- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- laser measurements

Results for

Laser measurements - Import export

QUELLTECH GMBH

Germany

Particular Challenges of the Application: By tactile equipment, determination of the deepest point on a rough metal surface is neither simple or precise. As a consequence, often either too much material is removed, or the surface is still covered with defects which have to be eliminated by a following milling cycle. The equipment is arranged in parallel, so that the complete width of the slabs is covered. The sensors are calibrated to a common coordinate system and mounted on a movable gantry. Before measurement, the slabs are fixed in place. The scanners mounted on the gantry are guided over the measuring object, driven by an electric motor. The point cloud recorded by the four scanners is consolidated in a PC by means of the QuellTech image processing software which calculates the difference between highest and lowest point of the corresponding surface and compensates for possible inclination of the slab (detrending).

Request for a quote

QUELLTECH GMBH

Germany

The QuellTech laser sensor family Q4 or Q5 used for these tasks is generally mounted on an arm of a rotational axis, to scan along the complete 360° angle of the internal surface in a sequence of strips. The Q4 sensors can also be used to control the weld seam tracking itself for rapid setup and ease of use. Even during a project, the range and scope of the Q Series sensor demonstrates the advantages of a modular system to quickly adapt to project needs, where the smallest system has provided fast analysis of pipes as small as 105mm. The low power, with standard communication protocols, enable battery powered systems to transmit wireless data to other systems for review and cloud back up.

Request for a quote

QUELLTECH GMBH

Germany

Many materials cannot be measured tactilely, therefore non-contact thickness measurements become necessary. Especially e.g. with glowing materials, or wet processes, a continuous tactile measurement is nearly impossible. Furthermore, web speeds in plant engineering and production have increased, requiring a corresponding fast sampling rate of the measuring systems. In addition, high measuring widths are often required. Why is contact free measurement technology so perfect for this application? Can be used in any web width, Scalable measurement thicknesses from a few millimetres to several meters, Thickness and coating thickness can be measured for different materials, Vibrations of the web materials, can be compensated, Turnkey solution for mechanical engineering, Non-contact and non-destructive measurement method, Large distances to the measured object are possible, Measurement of free forms,

Request for a quote

QUELLTECH GMBH

Germany

Q6-Lasor sensor – High Speed, High Resolution – Q6 Sets New Standards for 2D / 3D Measurement: Resolution of up to 0.6 µm Profile speed of up to 25.000 profiles/s Measuring ranges between 2 mm and up to 370 mm available Laser wave lengths starting from UV via blue, red and green through to IR The Q6 laser sensor series has already proven its ability in numerous industrial applications demanding a high degree of precision and process stability at increased travel speed. For common environments, connection is established via GIGE interface and GeniCam. Integration with linear axes and robots is possible by means of encoder inputs and trigger option.

Request for a quote

QUELLTECH GMBH

Germany

Rotationally symmetrical driving gears in a line producing for automotive industry are mutually connected by electron beam welding. The camera inspection carried out until was not able to assess the quality of the weld seams at the required precision. Non-contact laser measurement system Particular Challenge: As the welding seams show a high reflectivity and are located at a position hard to access, inspection is difficult, all the more so as they dispose of a width of only 500µm. Therefore it is quite a challenge for the laser measurement system. The QuellTech solution: A QuellTech Laser Scanner Q4-5 with extremely small shape factor and high resolution proved to be perfectly suited for this application. In order to suppress reflections from elements in the surroundings, a particular algorithm has been integrated. Furthermore, this laser measurement system features a particularly adapted laser wavelength and an ultrafine laser line.

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Handling the friction and steel discs into the measuring system from storage 360° laser measurement of the thickness of friction and steel discs Stacking discs with the respective high points offset to each other Measuring the disc pack for stacking height (pack class) and plane parallelism

Request for a quote

MICRO-EPSILON

Germany

Laser distance sensors are designed for non-contact distance measurements: laser gauges for measuring ranges up to 10m, laser distance sensors for up to 270m. These sensors are used for positioning and type classification in machine building and handling equipment.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE C.LP sensor systems use laser profile scanners for the thickness measurement. These scanners project a laser line onto the surface to be measured. The laser line compensates for strip tilting and enables profile averaging. The laser line measuring technique makes it possible to measure the thickness of structured materials such as embossed surfaces and perforated plates.

Request for a quote

MICRO-EPSILON

Germany

thicknessGAUGE C.LL sensor systems use laser triangulation sensors for the thickness measurement. These laser sensors enable high measuring rates at high speeds. The thicknessGAUGE.laser series impresses with a favorable price/performance ratio and is preferably used for thickness measurements of common surfaces such as plastics, wood and metals.

Request for a quote

MICRO-EPSILON

Germany

The optoNCDT 1220 is the entry-level model for precise measurements in industrial automation. This compact laser triangulation sensor measures displacement, distance and position with high precision. Based on an excellent price/performance ratio, this sensor is ideally suited to measurement tasks involving a large number of pieces. Therefore, the sensor can be used in all fields of automation technology, e.g., in machine building, 3D printers or robotics.

Request for a quote

MICRO-EPSILON

Germany

The optoCONTROL 1200 is based on the principle of light quantity measurement. The compact laser micrometer has all the evaluation electronics integrated in the case and the mounting is very flexible. High dynamic applications can be measured due to the measuring rate of 100 kHz.

Request for a quote

MICRO-EPSILON

Germany

scanCONTROL 30x2 laser scanners are powerful profile sensors in terms of size, accuracy and measuring rate. These laser scanners provide calibrated 2D profile data with up to approx. 8 million points per second. With a maximum profile frequency of 10 kHz, the scanners are designed for precise profile measurements in dynamic processes. The sensor matrix offers a resolution of 1,024 points with a point distance from 24 µm. This means that even small details can be detected reliably.

Request for a quote

MICRO-EPSILON

Germany

thermoMETER CTLaser pyrometers are used for both industrial measurements and R&D. Two laser beams mark the measurement spot which ensures precise temperature measurements. The smallest measurement spot is 0.5 mm. The thermoMETER CTLaser infrared pyrometers can be used with various measuring objects. From extremely low temperatures (-50°C) to the highest temperatures (975°C), these IR pyrometers measure precisely and reliably.

Request for a quote

MICRO-EPSILON

Germany

White light interferometers use infrared light in the non-visible range (approx. 840 nm wavelength), which means that the measurement position cannot be seen. To visualize the measuring position, Micro-Epsilon systems are equipped with a pilot laser which projects a light spot onto the measuring position. In addition, the pilot laser uses a patented method to provide feedback on the distance in addition to the measurement position. If the measuring object is at the correct distance and within the measuring range, a constant glow is emitted by the pilot laser. If the measuring object is outside the measuring range, the pilot laser flashes.

Request for a quote

WALTER UHL TECHNISCHE MIKROSKOPIE GMBH & CO. KG

Germany

for the measurement of control cams on plasic rings in automatic gearboxes.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9012 M has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction.A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Request for a quote

ZOLLER & FRÖHLICH GMBH

Germany

The Z+F PROFILER® 9012 A has a vertical 360° field-of-view and is the fastest profile imaging 2D laser measurement system in its class. With its scan rate of more than 1 million points per second and a maximum scanning speed of 200 profiles/sec. short distances between the profiles can be achieved even at high speeds of the carrier vehicle. Because of the high point density, even small objects are registered and processed by the software. Because the laser measurement system corresponds to laser class 1, the scanner can be used in urban environments without any restriction. A hardware-assisted pixel-by-pixel synchronization makes it possible to process signals form external devices. As a result, the position and orientation of the scan data can be determined.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ZOLLER & FRÖHLICH GMBH

Germany

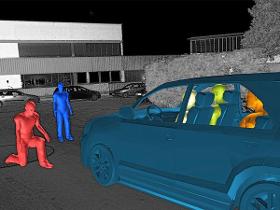

Within a few minutes, Z+F 3D laser scanners can provide accurate measurement data of crime scenes and accidents – indoors and outdoors. This data speeds up the investigation process by "freezing" the scanned crime scene and documenting it. These evaluations are accepted in court. Accident investigation The phase based 3D laser scanners of Z+F enable an accurate three-dimensional capturing of complete accident scenes with all the details like deformations of the vehicles or skidmarks. Using this technology, the question of the possible causes and sequence of the accidents can be analysed and answered more easily. Crime scene investigation The complete securing of evidence at crime scenes and the geometry measurement on the spot are of great importance. A crime scene is normally captured from various positions by the Z+F IMAGER®. By combining these scans, the viewer gets an overview of the complete scene.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

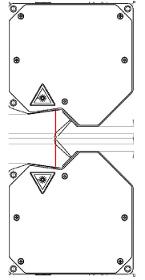

The optimum oscillation behavior of the ultrasonic sonotrodes is determined by means of FEM (Finite Element Method) calculation. Highest precision requirements in terms of CAD/CAM calculation algorithms guarantee precise 3D contours for sonotrode manufacturing. Measuring and documentation of the amplitude distribution is performed at the vibrating sonotrode using state-of-the-art laser measurement technology. Special surface finishings result in even longer service life spans of the ultrasonic sonotrodes.

Request for a quote

METZNER MASCHINENBAU GMBH

Germany

Metzner has developed a fully automatic processing machine with outstanding cutting quality and great length accuracy for steel cable wires of up to 20 mm diameter. The steel cable wires are fed by a motorised feeding device in combination with a contact-free loop control. Then, program-controlled and positionally accurate marking tapes are applied to the steel cable – with a cycle time of less than two seconds. In addition, a wax printer marks all the fastening and processing points that will be required for subsequent processing. This labelling method is carried out in a continuous process. The cut is then made using a special cutting process. Precise length accuracy is achieved by a special laser measuring system. A material stacker with a storage area of up to 12 metres ensures that the steel cable wires are deposited in an orderly manner. All cut steel rope can be stored and sorted according to length to allow it to be removed at a later point.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) approximately 114/113/165 cm Total weight approximately 490 kg Equipment Stepless adjustment of the seat depth via pneumatic spring Rotating fixation of the knee joint axis for optimum biomechanics Stepless adjustment of the lever arm Laser pointer for secure positioning of the joint axis* * Optional accessories Options 100 kg weight block (20 x 5 kg) Fine weight adjustment 1 kg SmartPanel compass 600 Medical LAN Isolator Position sensors Isometry measuring device Laser pointer positioning aid Movement limitation Holder for drinks bottle Holder for Zimmer frames Lordosis support proxotrain software

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Technical data Dimensions (L/W/H) approximately 106/113/165 cm Total weight approximately 420 kg Equipment Stepless seat height adjustment via pneumatic spring Stepless adjustment of the lever arm Steplessly adjustable lower body fixation* Laser pointer for secure positioning of the joint axis* * Optional accessories Options 100 kg weight block (20 x 5 kg) Fine weight adjustment 1 kg SmartPanel compass 600 Medical LAN Isolator Position sensors Laser pointer positioning aid Isometry measuring device Movement limitation Holder for drinks bottle Holder for Zimmer frames Lower body fixation, steplessly adjustable proxotrain software

Request for a quote

TOPTICA PHOTONICS AG

Germany

The wavelength meters of the WS series accomplish wavelength measurements with highest accuracy. Both cw and pulsed lasers with narrow-band emission can be examined, monitored and even actively controlled. Various models of the WS series are available, covering UV to IR wavelength ranges (192 nm - 11 µm). Based on a rugged Fizeau interferometer setup without any moving components, the wavelength meters provide quasi unlimited lifetime.The spectrum analyzers LSA and HDSA allow for multi-line or broadband spectrum of light sources like cw and pulsed lasers, gas discharge lamps, super luminescence diodes, semiconductor laser diodes and LEDs.

Request for a quote

ALPHA LASER GMBH

Germany

The ALW is a comfortable, ergonomic, and compact seated workstation that offers plenty of legroom, and which can be adjusted to the height of the operator via the height-adjustable foot plate. The observation lens offers a variable viewing angle from 10° – 50°, thus ensuring comfortable working. The closed, laser-proof housing makes the ALW a laser-protected workplace that can be used in a normal production environment without additional safety precautions. The laser system is easy to operate. In addition to configuring via the display, the laser parameters can be adjusted via the patented multifunction footswitch or adapted accordingly during welding. The large doors of the ALW can be opened wide. This facilitates easy loading.

Request for a quote

ALPHA LASER GMBH

Germany

This stable work table can be used with laser sources from 300 - 900 W, which are integrated in the work table. The modular design allows the use of various optics and focal lengths, so that you can optimally carry out your tasks. The system can be operated either manually - with our instantly responding joystick - and semi-automatically or automatically with the WINLaserNC software. When welding, workpieces are moved precisely on the three axes of movement of the work table. An axis of rotation is also available. The Z axis of the table lifts workpieces up to 450 kg. The laser and motion system are conveniently operated via the control console with an intuitive touchscreen. With the AL-TW you can weld without restricting the work area. This enables the processing of large workpieces. We support you with the implementation of the laser safety measures with our laser safety concept.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Detector head to measure LASER radiant power in W and LASER irradiance in W/m². Features: Low height detector with 7mm dia active area, 400 to 1100nm, for the usage with optometers and signal amplifiers, calibration certificate.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Detector for fast, time-resolved (ns) radiant power measurement of pulsed laser diodes and LEDs. Features: Integrating sphere for integration of laser modes and beam profile. Pulse waveform with peak power and pulse energy (in joules) of pulses with pulse lengths in the low ns range. Optional 7 mm measuring aperture for eye safety.

Request for a quote

SIM AUTOMATION GMBH

Germany

The product portfolio at SIM Automation ranges from the effective design of individual manual workstations all the way through to completely interlinked, highly automated process lines. We handle all common transfer systems and can thus offer solutions that are independent from the branches of our customers. In addition to all standardized joining, measuring, testing and inspection systems, our assembly plants can also implement the customer’s own processes, including: - Joining, screwing, bonding, riveting, welding (laser, ultrasonic, resistance) - Testing, measuring, inspecting (optical, tactile, electrical, thermal) - Robot systems - Linear systems (pneumatic, electrical, mechanical) - Cam-controlled drives, linear and handling systems Testing and inspection lines we have been involved in: - Electric high-performance gear components (up to 6 kV) - Electric central locking systems (vehicles)

Request for a quote

SCHÜTZ GMBH MESSTECHNIK

Germany

The Laser Mini offers a selective measurement of methane without interfering cross-sensitivities. The device monitors itself and is therefore almost maintenance-free. Thanks to the menu navigation in conjunction with supporting displays of the measurement history, absolute value, etc., the Laser Mini is easy and safe to use even by inexperienced users. The Laser Mini only needs to be switched on.

Request for a quoteResults for

Laser measurements - Import exportNumber of results

36 ProductsCountries

Category

- Sensors (9)

- Laser - cutting and welding machines (4)

- 3D scanner (4)

- Measurement - Equipment & Instruments (3)

- Machine vision system (2)

- Monitoring and control equipment (2)

- Optical measuring equipment (1)

- Adjustment - machine tools (1)

- Automation - systems and equipment (1)

- Mechanical engineering - custom work (1)

- Navigation - charterers (1)