- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- labelling machine

Results for

Labelling machine - Import export

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the accessories of printer, which function is for support stand.They were made by aluminum, then use CNC Milling machine to process, then doing black anodize.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are CNC turning assembled stainless steel parts.

Request for a quote

ALTMANN GRAPHISCHE MASCHINEN GMBH

Germany

age 1993 labelling machine semi automatic wet glue hand feeding box delivery Delivery time: immediately Ref: LA210185A Please ask for price. We ship and install worldwide!

Request for a quote

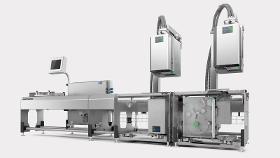

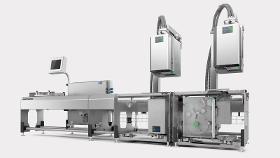

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The Automatic Weigh Price Label Systems from Bizerba. Introducing the GLM-Ievo 150 capable of weighing and labelling up to 150 packages per minute. Designed for automatic weighing and labelling of pre-packaged goods comes in different versions from the entry level intelligent weigh price goods labelling system GLM-Ievo 70 (70 packages per minute) to the GLM-Ievo 170 weigh price goods labelling system (170 packages per minute) Higher package rates are available upon request. Due to its modular design, it can be optimally configured for products and performance requirements in the industrial food production area. With the Bizerba _connect.BRAIN Industrial Software makes this system an even more attractive addition to your production plant. The intuitive software enables you to connect the Automatic Weigh Price Label Systems to existing third party hardware and software....

Request for a quote

BIZERBA SE & CO. KG

Germany

Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The GLPmaxx can be used as a label printer for product labeling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels. In combination with the Bizerba weighing technology it is the perfect starter kit for manual price labeling.

Request for a quote

BIZERBA SE & CO. KG

Germany

Suitable as a stand alone printer, total printer or for weight-related product labeling The Label printer GLP-Imaxx in combination with the Bizerba weighing technology is the perfect starter kit for manual price labeling. GLP-Imaxx is suitable for label rolls with a diameter of up to 300 millimeters. Thus retrofitting time is reduced - especially with large labels. The printers are network compatible and can also be controlled directly via the Internet. Settings and maintenance of the printer unit can be made without need of any tools - reducing costs and increasing print quality.

Request for a quote

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The Weigh Price Goods Labelling System with the Big 3: Performance, Plug-In® label and Quality Check Inside - with more customer benefits for any future requirements. The intelligent labelling line GLM-Ievo Weigh Price goods labelling system designed for automatic weighing and labelling of pre-packaged goods comes in different versions depending on the products that need to be weighed and labelled. Due to its modular design, it can be optimally configured for products and performance requirements in the food production area. Additionally they will seamlessly integrate with inspection systems. Thanks to the modular system, there are no limits for today and any future requirements in the industrial food manufacturing area. In addition to its flexibility, this labelling system stands out in terms of technology, robustness and an easy-to-clean design. With intelligent...

Request for a quote

BIZERBA SE & CO. KG

Germany

Big 3: Performance, Plug-In ® label and Quality Check Inside - more customer benefits for future requirements The weigh price labeller GLM-Ievo intelligently designed for automatic weighing and labelling of pre-packaged goods comes in different versions. The Weigh Price Goods Labelling System GLM-Ievo 170 will achieve over 170 packs per minute. Due to its modular design, it can be optimally configured for alternative products and offers exemplary performance requirements in the food production area. Thanks to the modular system of the weigh price labeller, there are no limits for todays and any future requirements you may have in the industrial food area. Besides its flexibility, this labelling system stands out in terms of robustness and an easy-to-clean design. With intelligent visual quality control and automated activation of process data via the new function Plug-In® Label operation it is easy to maintain and manage thereby reducing errors during the packaging...

Request for a quote

BIZERBA SE & CO. KG

Germany

High-tech meeting the highest demands. More customer benefits for future requirements Intelligent Weigh Price goods labelling system from Bizerba. Unique in it's class and recognised as the worlds leading experts in weigh price labelling systems for the food industry. High Speed High IP protection with intuitive BRAIN software. Easy to operate and maintain incorporating the Bizerba quick belt change system that does not require tools. The flexible system will easily incorporate into existing production lines seamlessly. Additionally the system will talk to existing software packages with our _Connect BRAIN software module. The Intelligent Weigh Price goods labelling system weighs, labels rejects inferior weights automatically. Depending on the speed requirements and the lines the Weigh Price Goods Labelling System can achieve up wards of 170 packages per minute. High-tech meeting the highest demands. More customer benefits for future requirements. The intelligent labelling...

Request for a quote

BIZERBA SE & CO. KG

Germany

Whether as a Windows® printer or part of a system network, the robust, stainless steel GLP-58 thermal printer impresses with its fast, reliable handling and multifunctionality. In combination with a range of Bizerba labeling systems, checkweighers and industrial terminals, it offers a wide variety of potential applications - both in manual labeling and statistical work. The label printer GLP 58-K on the ST terminal allows printing of up to three barcodes. It is possible to use not only standardized printing images but also custom layouts. The Windows® printer driver can be used to print out labels created using Windows® applications and the Bizerba Label Designer (BLD).

Request for a quote

BIZERBA SE & CO. KG

Germany

Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The GLPmaxx can be used as a label printer for product labeling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels. In combination with the Bizerba weighing technology it is the perfect starter kit for manual price labeling. The printers are network compatible and can also be controlled directly via the Internet. Settings and maintenance of the printer unit can be made without need of any tools - reducing costs and increasing print quality.

Request for a quote

BIZERBA SE & CO. KG

Germany

Industrial Barcode Label Printer with Thermal direct / thermal transfer printer for more features, more convenience, more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product labeling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today's and tomorrow's requirements. The Industrial Barcode Label Printer with Thermal direct and thermal transfer printer packed with more features, more convenience, and more functionality. Regardless if used as stand-alone printer, total printer or if used for weight-related product for labelling, the GLP maxx with its Intel® Atom™-based hardware is the ideal solution for today and tomorrow's requirements. Future proof your business. The GLPmaxx Industrial Barcode Label Printer can be used as a label printer for product labelling in the food processing industry as well as in manufacturing trade and logistics. It is perfectly suitable for dispatch and stock labels....

Request for a quote

AXRO GMBH

Germany

DYMO LabelWriter 550 (2112722) original & new

Request for a quote

AXRO GMBH

Germany

Zebra Label printer GK420t USB/Parallel/Serial color print (GK42-102520-000)

Request for a quote

AXRO GMBH

Germany

Colop e-mark Labelling Machine white (153111) Inkjet, 11.1 V Li-Ion, Up to 4 imprints can be saved

Request for a quote

AXRO GMBH

Germany

Special features: Inkjet, 11.1 V Li-Ion, Up to 4 imprints can be saved

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PDL model series for labeling Petri dishes from our special machine construction provides filled and sealed Petri dishes with a serialized DMC label in the minimum tolerance range at an output of 130 products/min. The system combines mechanical engineering, label material and thermal transfer printer. The Petri dishes from the previous filling/capping line are fed to the labeling system. By means of a clock star, the system transports the products through the various stations, such as labeling, the press-on unit and DMC inspection, where the grading (quality control) of the data matrix code takes place at the same time. In case of insufficient quality of the barcode, the product is ejected. By using our label dispenser RAPID SM we guarantee an accuracy of +-0.2 mm at a labeling speed of 60 m/min while maintaining the product quality. The signals are switched directly into the stepper motor card developed by us.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RML labeling machine is suitable for wrap-around labeling of non-rigid cylindrical products - ampoule, cartridge, syringe labeling. The products are transported to the labeling station, which fixes the label on the circumference, by means of an intermittent roller conveyor. The labeling system is suitable for products such as ampoules, cartridges, lipsticks, syringes and vials and is therefore suitable for the pharmaceutical, medical technology, cosmetics and food industries, where reliable labeling and control processes are extremely important. Deviations and errors here can lead to life-threatening situations. From manual loading and unloading to fully automatic loading and subsequent collection of the products, this model is modularly expandable. Particularly narrow products such as ampoules or cartridges can also be processed using format sets (RML-FS).

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

With the VFP labeller, pasta packages or other flat products can be labelled on the bottom or top. In various industries such as food or cosmetics, and especially pharmaceuticals and medical technology, accurate product labelling is important. Food packaging or folding boxes are often labelled on the top and bottom. Like all systems, this labeller from b+b is modularly expandable. Processing of different product sizes and formats is possible without tools by simply changing over from format to format. Your advantages here are short set-up times and easy handling. The fully automatic VFP labelling system enables you to label your products precisely - regardless of whether the label is to be applied to the top, the bottom or both sides.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

This manual labelling solution was developed to apply one or more seal labels to folding boxes in small batches - before fully automatic lines are changed over to the product, the products are already sealed with this device. The seal label can be applied to all closure flaps as required. An ultrasonic fork sensor enables the processing of transparent and non-transparent sealing labels. Label roll-on across corners is clean and accurate. The solution for smaller, decentralized labeling jobs: — suitable for transparent/non-transparent (ultrasonic label sensor) — reliable, handy with handle bar — non-slip stand — easy setup — repeatable application of labels — core diameter: 76 mm — max. outer diameter: 200 mm — max. label width: 80 mm — label winding: outer winding

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

With the TNC-L model series, cardboard boxes and small cartons are provided with sealing or closure labels. The system can be infinitely adjusted to different formats. We determine the format range together with the customer. Optionally, labelling can also take place at several points - for this purpose, the product must be relocated in the system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The PAE range is an innovative new generation of pallet labellers that can label pallets on up to three sides with either pneumatic and/or electric traversing axles. The labels are printed with individual data in real time immediately before dispensing. The series is designed to integrate thermal transfer printing modules from different manufacturers. Automatic height adjustments are available as an option in order to Application heights on the pallet to start up. The complete traceability of products is essential nowadays, which is why interest in intelligent pallet labelling processes is so high. The system can handle label formats up to DIN A4 format, enabling product labelling according to the global GS1 standards.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Due to increasing product counterfeiting, many manufacturers are forced to make their products tamper- and counterfeit-proof. Legal requirements exist in some countries for this purpose. Our TE model was developed for this task. The system enables single-sided and/or double-sided seal labeling of pharmaceutical folding boxes and can also be used in the cosmetics industry. During the development, special attention was paid to the protection of the packaging as well as the format range of the products to be processed. The basic version labels folding boxes with format widths (in the running direction) of 50-250 mm at an output of up to 300 folding boxes per minute. Models for processing wider folding cartons are based on the same line concept. As an extension, the model series is available as a combination system (TE-PV) with a b+b serialization module and b+b LineManager. In this case, the printer and camera system are integrated into the system.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Our printing and apply systems from the CLM model series are designed for use in the final packaging predestined. To labelling of their cardboard boxes, printing widths from 54 mm to 216 mm (2“ to 8“) are available. In addition to the selection of the desired printing width the customer can choose between one- and two-colour printing. decide. The latter is e.g. helpful in the implementation of the GHS Regulation in the chemical industry. In interaction with our label design software Labelsplatform 4 you decide to choose the ideal and future-proof complete package.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

We offer the TNC-2F model for labelling large square containers such as canisters or cartons on one or more sides. For this purpose, the operator places the product in an adjustable product pick-up station. As soon as the operator actuates the foot switch, the labelling process is started, and the labels are applied. Model TNC-2F-2 | 2- sided labelling with 2 apply systems TNC-2F-3 | 3- sided labelling with 3 apply systems

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Our HSF-eco model is used for offline labelling of flat products such as empty pharmaceutical boxes, postcards or cardboard blanks. After loading the infeed magazine, the system unstacks the inserted products fully automatically and collects them again after labelling. The system can be refilled during operation and the processed products can be removed. In the basic version, product widths of 350 mm can be easily labelled. Models for processing wider products are optionally available.

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

Like all of our labelling systems, this model has a modular design and can be expanded at any time. The advantages such as low set-up costs, high availability and multiple use in different production lines are obvious. The adaptation to the different products takes place by simple adjustment of the machine components and is possible without tools. The VRM-DS model includes a 3-roller turning station and can be used for an output of up to 60 products per minute. It is characterised by the highest labelling accuracy and can optionally align the products using a welding seam, print mark or other feature before labelling (target zone labelling). For larger quantities of up to 250 products/ min the VRM-RB model is used. Model: VRM-DS | Cylindrical and quadratic products | up to 60 products/min VRM-RB | Cylindrical and quadratic products | up to 250 products/min VRM-DSRB | Cylindrical and quadratic products | up to 250 products/min

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

For precise labelling, products with an accessible cavity are manually placed on a format mandrel. By actuating the foot switch or the optionally available 2-hand control, the labelling process is triggered, the product is rotated, and the label is applied precisely to the circumference of the product. If front and back labels are on one label roll, the system can also place several labels on the circumference. The distance between the labels can be adjusted in the PLC. Optionally, the labels can be aligned using a welding seam or other product features (such as opening tabs or lid recesses for tubes). A pneumatic ejection makes the removal process superfluous and blows the well labelled products into a collection box

Request for a quote

B+B AUTOMATIONS- UND STEUERUNGSTECHNIK GMBH

Germany

The RSA Series is designed to identify suspension springs with the appropriate load class based on an individual payload measurement result. The system receives the measurement results from the upstream system. The system is available as a single or double cycle version (depending on the required throughput). Simple linear axes, single- or twin-robot systems are used as handling systems. Since the labels are normally wider than the distance between the threads, the label is preformed (Ushape) before application to reach the labelling position before it is placed around the wire and finally fixed as a flag label. The data is inspected by a vision system and compared with the original measurement information at the outfeed of the system (verification). The labels are printed in the system with various data such as customer information, barcodes and line information. The data for this is made available via the main control of the production line.

Request for a quoteResults for

Labelling machine - Import exportNumber of results

119 ProductsCountries

Category

- Labelling machines (102)

- Food industry - machinery and equipment (16)

- Printers - computer (5)

- Chemical and pharmaceutical industry - machinery and equipment (2)

- Cleaning and maintenance products, household (2)

- Lubricants, industrial (2)

- Office supplies (2)

- Bottling and filling - machinery and equipment (1)

- Labels - stationery (1)

- Custom packaging (1)

- Branding equipment (1)

- Conveyor belts (1)

- Pharmaceutical industry - machinery and equipment (1)

- Potting equipment (1)

- Silicones (1)