- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- interface test

Results for

Interface test - Import export

TAVRIDA ELECTRIC

Germany

Custom designed tool for primary and secondary injection testing of Rec15/25 protection and automation functions.

Request for a quote

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The 220 is a large capacity lightfastness tester dedicated for textile testing. It comes with premium on-rack light and temperature sensor and non-aging optical filter technology. With the ability to test 38 samples, the 220 provides nearly twice as much capacity in the same footprint compared to 150S+. The combination of its large test chamber and the efficient use of power and water make it today’s most economic air-cooled instrument available. It complies to standards ISO 105 B02, AATCC TM16 (option 3), and Marks & Spencer C9, C9A. 1x 2200 W air-cooled Xenon Lamp 2310 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct Setting and Control of Irradiance (300-400 nm) Direct Setting and Control of Black Standard Temperature Direct Setting and Control of Chamber Temperature Direct Setting and Control of Relative Humidity Display of Diagnostic Message Storage for 10 user-defined tests Multilingual User Interface Non-aging filter systems for ISO 105-B02 and AATCC TM16 On-rack XENOSENSIV® for measuring and controlling irradiance (in W/m²) and Black Standard Temperature on sample level Selectable temperature control either by Chamber Temperature (up to 65 °C) or by Dual Control: Chamber Temperature and Black Standard Temperature (up to 100 °C) simultaneously Fan-controlled temperature difference between Chamber and Black Standard Temperature Ultrasonic humidification system with integrated 60l water reservoir for humidity control (automatic refill) Sample rack suiting 19 sample holders with capacity for 38 standard textile samples Pre-programmed standards ISO 105 B02 and AATCC TM16-2004 (Option 3) Switch-off by radiant exposure, light exposure or total operating time UV-protected test chamber window Advanced Auto Start functions Internal memory chip for storing instrument data Data output via Memory Card or RS 232 Ethernet interface plus XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“) XenoCal BB 300-400 XenoCal BB 300-400 BST XenoCal BST

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The Xenotest Beta+ FD is a premium stand-alone rotating rack xenon instrument with 4000cm2 exposure area. It’s completely target designed to meet the testing needs of the FMCG industry, such as drinks, foodstuffs, personal care or household products. Beta+ FD enables consumer goods manufacturers to test their products realistically within very short test times, typically with acceleration factors between 10-50 versus real time. It’s for reliable qualification of stable product formulations, determination of appropriate packaging materials, and supporting product shelflife claims. Beta+ FD offers two custom racks - a bottle rack and a packagings rack. Both carry loads up to 20 kg and fit various packaging shapes and sizes. Economic non-aging filters guarantee realistic simulation of all three common light conditions - outdoor Daylight / indoor Daylight / Supermarket light, while a chiller keeps test temperatures on realistic levels even at high irradiance. Programming and monitoring can be done online. 3x 2200 W air-cooled Xenon Lamps 4000 cm 2 exposure area Touch screen with colour display to monitor and display test parameters Direct setting and control of Irradiance (300-400 nm) or (300-800 nm) Direct Setting and Control of Black Standard Temperature (BST) Direct Setting and Control of Chamber Temperature (CHT) Display of Diagnostic Messages Storage for 10 user-defined test methods Multilingual User Interface Test chamber with rotating rack technology; for application-specific specimen racks Thermal insulation of test chamber and periphery preventing water condensation Non-aging XENOCHROME filters to simulate outdoor daylight, daylight behind window Optional StoreLight filter to simulate supermarket light conditions On-rack XENOSENSIV 300-400 nm or 300-800 nm sensor for measuring and controlling irradiance (in W/m²) and BST (C°) on sample level Selectable Temperature control either by CHT (10° *- 70°C; *with chiller) or by CHT and BST (25° * - 120°C) simultaneously (dual control) Fan-controlled temperature difference between Chamber and Black Standard Temperature Chiller SunCool Beta+ for extended CHT- and BST-ranges towards lower temperatures UV-protected test chamber window Switch-off by radiant exposure, light exposure time or total operating time Advanced Auto Start functions Internal memory chip for storing instrument data Data output via memory card or RS 232 interface Ethernet interface for connection to internal computer network and use of XenoTouch Add-ons 1, 2, and 3 (“Remote Control“, “E-Mail Service“, “Online Monitoring“)

ATLAS MATERIAL TESTING TECHNOLOGY GMBH

Germany

The CCX is the most advanced, sophisticated and versatile laboratory corrosion testing cabinet. With installed options, it can replicate up to 15 environmental conditions, placing powerful capability in the hands of the user. Advanced cyclic tests are used to qualify a specific coating or material for a wide range of end uses, to quickly qualify a coating or material on a pass-fail basis, to predict service life or determine the probability of corrosion of a specific material. Applications include: Aerospace, Automotive, Research, Electronics, Government, Military, Paints/Coatings, Robotics, and Telecommunications. Reinforced fiberglas cabinet - Exposure zone lined with gel coat Solution reservoir - 60 gallon (227 l) Exposure zone heated by titanium rod heater Polypropylene cover with water seal - CCX9000 only Peaked cover prevents dripping of condensation onto samples Clear cover with dual magnetic Santoprene gaskets Heated humidifying (bubble) tower with air relief valve Exposure zone temperature up to 160 °F (71 °C) - high temperature option up to 194 °F (90 °C) Specifications and Dimensions (Testing Volume, Exposure Zone Dimensions, External Dimensions) CCX2000 - 565L, 1.27 x 0.74 x 0.63 m, 2.4 x 0.9 x 1.4 m CCX3000 - 850L, 1.91 x 0.74 x 0.63 m, 3 x 0.9 x 1.4 m CCX4000 - 1130L, 1.91 x 0.94 x 0.63 m, 3 x 1.1 x 1.4 m CCX9000 - 2550L, 1.93 x 1.14 x 1.16 m, 3.05 x 1.3 x 2.16 m CCX11000 - 3115L, 2.27 x 1.86 x 0.76 m, 3.12 x 2.59 x 2.13 m Standard Controls Features Programmable Logic Controller with Operator Interface Panel Five Pre-loaded Test Methods for Immediate Operation Storage of up to 15 Test Profiles with up to 18 Steps Pressure Gauge for Bubble Tower Premium Controls Features Notebook Computer with Color Screen, PC-compatible Seven Pre-loaded Test Methods for Immediate Operation Display of up to 50 Test Profiles with up to 100 Steps Display Graphing on Notebook Monitor Operator Interface/Datalogging Software Pressure Transducer for Bubble Tower Solution Reservoir Fill with Automatic Shut-off SO2 Injection System High voltage kit High capacity oil: water separator External condensate collection system(to check collection rate of fog with cover closed) Air actuated cover, automatic ambient Solution spray (direct impingement) Power exhaust kit Water fog, automatic Custom sizes (extra height or any LxW) and configurations (pass-through electrical/mechanical ports) Cabinet options choices: Standard controls. Two pen circular chart recorder with digital display (wet bulb and dry bulb), recorder/6 channel strip chart (4 temperatures, air pressure), modem for remote trouble shooting / Premium controls Controlled, Adjustable RH with direct RH Sensor; required for SAE J2334 Color Touchscreen Upgrade Data Recording PC Software; output to customer's computer- DB/WB/BT temps Immersion Option, Automated - CCX2000/3000/4000; recommended for SAE J2334 Immersion Option, Automated - CCX9000; recommended for SAE J2334- 1250 Immersion Set-up Kit; required for future addition of Immersion Option LN2 Freezing/Cooling System; using customer-supplied liquid nitrogen; to 30ºC Mechanical Freezing/Cooling System; to 30ºC; includes Controlled RH Automatic Retractable Housing; for RH sensor Very High Temperature 90ºC; for Dry Cycle operation, CCX2000/3000/4000 Very High Temperature 90ºC; for Dry Cycle operation, CCX9000/11000 Solution Spray; multiple nozzles (8, 12 or 16) w/ separate shut-off valves Volume Marker and Overflow Protection; for Solution Reservoir CCX Exhaust Recirculation System; for Salt Fog and Water Humidity steps only - not for use during Freezing/Cooling or Very High Temp 90ºC options

MERECS ENGINEERING GMBH

Germany

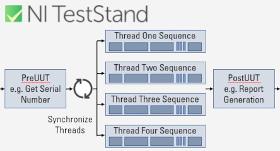

As an NI Alliance Partner, we use NI TestStand and NI LabVIEW for test automation. Python, C/C++ Embedded and Microsoft PowerBI can be used in addition. NI-TestStand is the industry standard test management software and is used by the developers and architects at Merecs Engineering with a lot of experience. We offer for example the following services: - Requirements analysis based on the DUT properties to be tested - Development of test cases in cooperation - Sequence development in TestStand - Intuitive custom user interfaces - Parallel testing of many DUTs & Badge Testing - Reporting (SQL databases etc.) - Trainings & Workshops Our developers hold the CLA (Certified TestStand Architect) and CLD (Certified TestStand Developer) certificates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAVRIDA ELECTRIC

Germany

Custom designed tool for secondary injection testing of Rec15/25 protection and automation functions.

Request for a quote

PROXOMED® MEDIZINTECHNIK GMBH

Germany

Interfaces To the proxomed test and training systems as well as to external patient management systems such as Theorg (Thedex) or KIS (HL7) Functional modules proxOS connect tergumed proxOS connect IPN-Test Suite proxOS connect MediMouse proxOS connect Biodex S4 proxOS connect MFT S3-Check proxOS connect goldenage proxOS connect HL7 proxOS connect Thedex proxOS connect mobile proxOS connect SmartPanel proxOS connect evaluation station proxOS connect proxonetwork proxOS connect proxotrain

Request for a quote

FRIWO GERÄTEBAU GMBH

Germany

Enable-Tool NG Professional is used for the adjustment and maintenance of our control units in development, production and after - Read error memory - Setting of a limited number of parameters per control unit - Creation of signed data records for production and aftersales - User roles (developer, production, service) for controlling vehicle projects in larger organizations with a dealer network - Creation of signed data records for production and aftersales - Storage and transmission of data sets - Interface to End-of-Line Test Additional information •Interface: USB •System requirements: Microsoft Windows, Dualcore CPU @ 1.8 Ghz, 2GB RAM, 100MB HDD •Read fault codes: Service and developer •Change parameters: Developer •Create datalog: Service and developer •Create data snapshot: Developer •Transfer data snapshot on a certain OEM ECU: Service •Transfer data snapshot all OEM ECUs: Developer •Connectivity: Active online connection

Request for a quoteResults for

Interface test - Import exportNumber of results

9 ProductsCountries

Company type