- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- insulator manufacturing

Results for

Insulator manufacturing - Import export

WERNER LANGER GMBH & CO. KG

Germany

For companies from the construction supply industry, we manufacture among others insulating mat holders and plastic dowels in a variety of lenghts. In the sanitary sector, our portfolio/range varies from drainage components through radiator holders in individual parts as well as complete modules to plastic parts for shower cubicles. We also produce components for sealing systems for windows and doors.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

In the insulation material industry IFA Technology has established itself internationally as a reliable partner in many important production and processing steps. In close cooperation with our customers, we always develop economical solutions to meet the constantly changing requirements of the market. We consider your individual requirements and build customised plants and systems for the insulation materials industry. In the field of mineral wool insulating materials, we specialise in manufacturing binder mixing systems and process water treatment plants. In this segment in particular, the properties of insulating materials are constantly changing. Together with our customers we continuously develop new systems to meet the requirements of the market. Thanks to many years of know-how, we are always able to implement the most economical solution from the customer's point of view.

Request for a quote

TEPROSA GMBH

Germany

Baking varnish is a special joining technology for sheet metal packages. After the individual lamellas have been cut, electrical steel with a baking varnish coating is baked into a sheet metal package in a two-stage temperature step. The result is a full-surface, solid connection between the individual sheets with complete insulation. Sheet metal packages manufactured in this way have high precision and perfect magnetic properties. Advantages of the Backlack process: The Backlack process offers several advantages over alternative packaging processes, which we will discuss in detail below. Precision – Sheets coated with baking varnish are baked over the entire surface. This means that even delicate slats can be assembled precisely.

Request for a quote

FRIMO GROUP GMBH

Germany

Processing sound-absorbing materials such as textiles, carpets or foamed materials requires efficient and high quality system technology. FRIMO supplies tailor-made solutions for insulation and acoustic component manufacturing for vehicles or other applications which require noise-cancellation.

Request for a quote

PANEL SELL GMBH

Germany

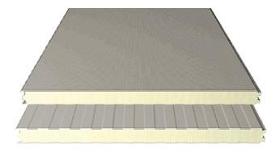

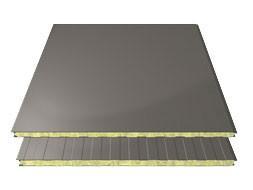

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

PANEL SELL GMBH

Germany

For commercial buildings, coldrooms, Panelsell are able to supply sandwich panels quickly and in large quantities. Insulated sandwich panels (also known as insulated sandwich boards, or composite panels) are essentially two profiled metal sheets with an insulated layer material in between. Standardly, the outer sheets are made from steel. However, for special purposes, stainless steel or aluminium can be incorporated. The standard sheet thicknesses range between 0.5mm to 1.0mm. Therefore, it can be produced in other strengths as required. The wallpanels commonly have the Eurobox-marked profile on the sheet. However, smooth and micro-ribbed surface finishes are also possible. The standard core insulation of these composite wall panels is rigid polyuerethane foam (PU/PUR). Increasingly more popular are panels with a core insulation consisting of rockwool or polyisocyanurate foam (PIR) due to fire-protection requirements. The panels would have fire-rating classes, and involves non-combustible materials. The wall panels are assembled together in what is known as a "tongue and groove" system. The panel attachment can come as open or secret fixing. In open-fixing panels, screws that are mounted would be visible, whereas secret-fixing joints would conceal the screws when mounted. On request, we can offer the full range insulated wall panels manufactured new as tailored to your requirements in length, thickness and most RAL-colour tones. Of course, we are also able to offer you alternative special surplus stock items and cancelled orders at low prices.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

NEOPOR® MEANS OPTIMAL INSULATION. As soon as packaging not only has to protect, but also insulate, Neopor® is used, a version of Styropor® that contains graphite. The expanded foam features impressively low thermal conductivity combined with high compressive resistance, providing the basis for energy-efficient solutions. Among other things, Storopack uses Neopor® to manufacture insulating boxes for packaging and shipping temperature-sensitive products such as food and medicines. Insulating boxes and system solutions made of Neopor® ensure that goods are always kept within a set temperature range, independently of the active cooling system in the laboratory, warehouse, or truck. Thanks to outstanding heat and cold insulation properties, high compressive resistance, reliable shock absorption, low weight, and guaranteed low moisture absorbency, Neopor® packaging is not only tailor-made for products, but also secure and temperature-resistant.

Request for a quote

STOROPACK HANS REICHENECKER GMBH

Germany

NEOPOR® MEANS OPTIMAL INSULATION. Neopor® comes into its own when perfect insulation is called for. The expanded foam is a version of Styropor® that contains graphite with insulation properties that are ten percent better. The very low thermal conductivity combined with high compressive resistance makes it the perfect material for technical molded parts. Storopack uses Neopor® to manufacture insulation elements for building sections such as the roof and walls as well as perimeter bases and panels for laying underfloor heating systems. Up to 70 percent of heat energy can be saved with Neopor® thermal insulation compared to homes with no exterior insulation. Storopack products made of Neopor® are used in heating and air conditioning applications for insulating boilers, pumps, and heating controls and as housing for modern home ventilation systems. The technical molded parts can be expanded to optimally fit around contours so that no heat is lost.

Request for a quote

GARNTEC GMBH

Germany

The thinnest paper yarns in the world ! Paper cable yarns are used to obtain a regular air space between the copper conductor and the paper insulation. The yarns must have an exact diameter and may not become flat being wrapped on the conductor. Furthermore, the paper cable yarns can be used to exact standard measures as center elements or filling string. The raw material basis of our products are special celluloses of those the necessary special paper is made. For the thinnest yarns GarnTec is world class specialist and possessing the required know-how. In some sectors we are even sole supplier. Range of application: - telephone cable manufacturing - carpets and carpet bases manufacturing - candle wicks manufacturing (as substitute for lead or as reinforcement of the cotton fabrics) - insulation material manufacturing (as reinforcement) - Textile fabrics in combination with other yarns (e.g. for car seat and furniture covering)

Request for a quote

HELANTEC GMBH

Germany

The HELOX 4 has been a proven test instrument for quality control of IG units for more than 30 years. The analyser is preferred by test institutes and the central labs of the insulated glass manufacturers. A paramagnetic measuring cell that selectively measures the residual oxygen, and which consequently is the primary measurement method, is used as the measuring technology for this analyser. This has the advantage that the user does not need to know which gas type is in the IG unit. On the display the gas concentration of the gas sample is shown. A rechargeable battery can be integrated as an option, which enables the devices to also be used directly on the construction site. A sample is injected with a gas syringe. This offers the advantage that only minimal gas quantities are required and you can check the function of the gas analyser yourself.

Request for a quoteResults for

Insulator manufacturing - Import exportNumber of results

12 ProductsCountries