- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- installations

Results for

Installations - Import export

SCHOLPP GMBH

Germany

Installation: set up as before. Or even better. After we’ve unloaded, moved in and positioned your machinery and systems, that’s when it gets really interesting for our experts. The precise alignment of each individual part and meticulous millwrighting are key here. Our specialists then carry out the electrical and pneumatic reassembly. Once all the internal connections are in place, we then connect your machines to all the necessary utilities. Our teams use state-of-the-art measurement techniques in each and every step. They level the machine axes and adjust the system following the information recorded prior to disassembly and the manufacturer’s technical specifications. Then the way is clear for rapid commissioning and a successful start to production. SCHOLPP staff don’t guesstimate – precision is what you need when it comes to installation.

Request for a quote

HILGEFORT GMBH

Germany

Installation – maximum concentration on site If desired, Hilgefort can also assemble the plant components and perform final Installation and commissioning on-site. We will also be happy to provide instruction on use of the plant component and assistance in the event of unforeseen difficulties occurring during the Installation. Even years after commissioning, you can rely on us as an expert contact partner for help with any other issues, such as wear. Experience and skill – even in sensitive areas For many years, we have also been responsible for performing the final assembly of plant components produced by us in our customers’ industrial facilities and factories. Hilgefort experts have all the necessary qualifications to be permitted to work on sensitive factory premises, such as those in the chemical and petrochemical industry. Our construction supervisors and assembly personnel are certified by the SCC, which governs (occupational) health, safety and environmental (HSE)...

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

This installation includes cable duct construction, cable laying, connection of the control cabinet, components and drives, and grounding in accordance with regulations.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

Many devices and machines are still moved by compressed air. The necessary hoses are professionally installed by us.

Request for a quote

SPIROL

Germany

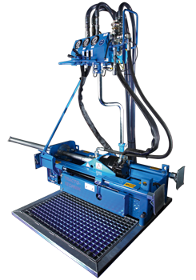

An accurate and consistent method to install virtually any Compression Limiter into plastic applications requiring up to 4.5kN (1000 lbs). Install just one Compression Limiter into one assembly, or several Limiters across multiple assemblies simultaneously for increased productivity. The Model CP’s quick-change tooling creates the flexibility to adapt the platform to a variety of products within seconds. The Model CP has a 230mm x 280mm (9”x11”) work area and is built on a rigid steel frame with high-precision shafting and linear bearings resulting in smooth operation, precise positioning, repeatability, and durability. The Model CP is available with optional enhancement features for error-proofing and maximum efficiency.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We install the necessary hoses between hydraulic power units and press cylinders. We also create piping and circuits for thermal oils and cooling water.

Request for a quote

SPIROL

Germany

SPIROL Pin Inserters feed all common types of pins — headed or straight — as well as Bushings, Rivets, Press-In Inserts and many other similar components. Whether your requirements are for a standard Pin Inserter (with or without fixturing) or a custom designed system, our objective is to build reliable and cost effective equipment that provides the right degree of automation based on the volume and complexity of the assembly process involved; the degree of automation that yields the lowest per unit assembly cost and the optimum pay back.

Request for a quote

SPIROL

Germany

This versatile tool is ideally suited for low to moderate levels of production for assemblies that require installation forces up to 22.2 kN (5,000 lbs). The Model PMX Extra Heavy Manual Pin Inserter easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. This Extra Heavy Duty Manual Pin Inserter will provide smooth operation, repeatability and durability.

Request for a quote

SPIROL

Germany

This exceptionally versatile tool for post-mould assemblies is ideally suited to all levels of production: from a single unit for prototype assembly, to multiple units on an assembly line. The SPIROL® Model CM Manual Compression Limiter Installation Machine easily accommodates quick change-overs by simply: • Replacing the fixture • Swapping insertion punch/pusher tip • Adjusting the positive stop for new install height. The use of high quality shafting and bearings results in smooth operation, precise positioning, repeatability, and durability. The Model CM Manual Compression Limiter Installation Machine installs Compression Limiters ranging in diameter from M3 to M10 metric and #4 to 3/8" unified, and has a maximum insertion force of 0.9kN (200 lbs).

Request for a quote

SPIROL

Germany

The Model CLX operates the same way as SPIROL's Model CL, yet this extra-large Compression Limiter Installation Machine is custom-designed to accommodate larger assemblies outside the standard footprint of the Model CL. Visit www.SPIROL.com to learn more!

Request for a quote

SPIROL

Germany

This robust, vertical installation machine is specifically designed to install Compression Limiters into a variety of plastic components. The machine is available in two models: the CL1000 is capable of 4.4 kN (or 1,000 lbs.) of installation force and the CL2000 is capable of 8.8 kN (or 2,000 lbs. of installation force, and is available with multiple installation tips in nearly any configuration at various elevations. The incorporation of a touchscreen operator interface machines makes our machines easy to use and customisable. Language conversion is easily executed to support international use. The Model CL is equipped with installation verification to ensure that the machine has completed a full installation cycle and a Compression Limiter was installed at each location. This highly flexible platen style machine with 228mm x 279mm (9" x 11") working area. The Model CL is available with optional enhancement features for error-proofing and maximum efficiency.

Request for a quote

SPIROL

Germany

SPIROL offers robust, vertical installation machines specifically designed to post-mould install Compression Limiters into a variety of plastic assemblies. The machines can install a single Compression Limiter or multiple Compression Limiters simultaneously into various polymers, thermoplastics and thermosets. SPIROL’s Compression Limiter Installation Machines are versatile solutions designed to be retooled to accommodate changing part configurations. All designs incorporate standardized machine components to reduce factory lead time, improve component reliability, and lower component costs. SPIROL also specializes in application-specific fixtures to ensure that all assembly components are held accurately in place through the installation process.

Request for a quote

SPIROL

Germany

The Model PMH easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. The precisely machined rack and casting results in smooth operation, precise positioning, repeatability, and durability. The Model PMH Heavy Duty Manual Pin Inserter installs pins ranging in diameter from 0.8mm-10mm (.031”-.375”) with a maximum insertion force of 6.7 kN (1,500 lbs).

Request for a quote

SPIROL

Germany

This exceptionally versatile tool is ideally suited to all levels of production: from a single unit for prototype assembly, to multiple units on an assembly line. The Model PM Manual Pin Inserter easily accommodates quick change-overs. The part holding device (fixture) is simply replaced from the base of the machine. The pin diameter is easily changed, positive pin depth easily adjusted, and part size variation easily accommodated. The use of high-tech shafting and bearings results in smooth operation, precise positioning, repeatability, and durability. The Model PM Manual Pin Inserter installs pins ranging in diameter from 0.8mm-4mm (.031”-.156”) with a maximum insertion force of 0.9 kN (200 lbs).

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

This is a plactic cover,used for machine accessories.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

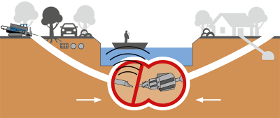

Working space diameter = 60 cm Operation and connection above ground Safer spoil removal with suction excavator Detectable and steerable bore head Drill rod length 230 mm Bore length up to25 m Max. upsizing diameter = 90 mm Thrust and pull back = 40 kN Torque = 850 Nm / 60 rpm

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDOPIT Power GRUNDOPIT Manhole GRUNDOPIT Keyhole Technical Data

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRACTO-TECHNIK GMBH & CO. KG

Germany

optimal PE pipe installation in the cold season (from 5°C ambient temperature) to prevent the machine from freezing

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

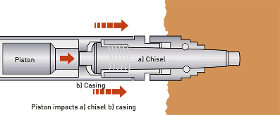

Pre-stroke Pulverizing Relocation Penetration

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

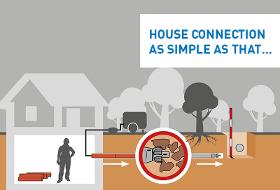

For Property service connections Advantage:Installation of casing and medium pipes for all utilities (gas, water, sewage, power, communication and fibre optic cables) with direct pipe installation for all common pipe types 15 – 20 m through the front garden without the need for trenches Advantage:No trench – no subsequent reinstatement, staircases, garden walls and other surface obstacles are simply bored beneath The GRUNDOMAT can be launched directly from inside of the building Advantages: No access hole in front of the building, shorter installation times, lower costs Wall ducts from our system partner (building seals by our system partner) Advantage: Reliable sealing of the cored brickwork walls (secure sealing of masonry) Several property services connections can be established in one day. Advantage: Greater efficiency, lower costs

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

Easy mounting by dismantling the system components Highprecisioninstallation Simple, time-saving machine alignment Equipment: rig, core borer, steering bore head, winged bore head for upsizing, re-usable retrievable pipes, augers Walk-over detection system

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

7 powerful machine types The slim design allows drilling with minimal clearance to buildings High corrosion protection, e.g. due to fully galvanised rod boxes The engine hood is made of weather-proof GRP The electronics are shock- and vibration-proof High quality manufacturing and certified supplier components (motors, pumps etc.) Highly resilient, fail-safe and service reduced High value stability Wide range of applications Compatible with tensile load measuring unit with bore data log according to the latest standards Additional safety: prototype testing by the trade organisation

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

For controlled and steered bores, In limited space, for high precision requirements, For house service connections on sloping terrains, beneath stairs, walls etc., bores that can’t be established using a soil displacement hammer up to 50 m bore lengths, For bores directly out of the building, as the machine is able to be dismantled, For bores out of manholes from 1 m diameter on (PIT S), For a quick, clean and economic jobsite execution.

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

GRUNDOMAT GRUNDORAM Machine technology Application range GRUNDOPIT GRUNDODRILL GRUNDOBORE Software Maxi HDD rigs Pipe and cable plows

Request for a quote

TRACTO-TECHNIK GMBH & CO. KG

Germany

UNDERCROSSINGS Road crossings and property service connections are everyday tasks for the GRUNDOMATN hammer. PIPE RAMMING FROM MODEL 130 GRUNDOMAT Ncan also be used for ramming in steel pipes by attaching a special ram cone to the head of the machine. PIPE BURSTING FROM MODEL95 Modified soil displacement hammers are also applicable for pipe renewal using the pipe bursting method. PILING Grundomats are also ideal for vertical use, e.g. piling for laying foundations.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

REB 420 - for tube-Ø from 4-20 mm Our type REB axial forming machines, with their compression power of up to 287,000 lbs, are particularly well-suited to effortlessly master complex geometries. With up to 6 forming steps in combination with an additional clamping unit, they will satisfy almost all requirements. The operation is simple and intuitive with a touch panel. The sequence control makes each separate movement of the respective forming step user-friendly and fully programmable. We offer the option to equip our systems with electric or hydraulic-numerical drives. These forming processes can be completed stepwise in transfer systems to achieve very short cycle times. Simultaneous axis movements ensure fast production processes and an efficient and highly dynamic production.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

The type UMR tube forming machines use smart operating technology with many predefined settings that can be retrieved automatically to achieve perfect mirror-like surfaces. When producing flares with 20°-90° angles, with a clamping length of 1 x D, the machine achieves perfect sealing surfaces. Flaring up to 90° can be produced in a single cycle. Tools can be changed extremely quickly. With the appropriate tools, the machine can also close tube ends.

Request for a quote

SPIROL

Germany

SPIROL's Model DP self-contained vertical drilling and pinning machine is ideally suited for moderate to high production applications that require accurate drilling and pinning of assemblies. The concept of drilling and pinning with one system eliminates tight tolerance and precision drilling of individual components to ensure proper alignment of holes for assembly. The Model DP Drilling and Pinning Machine consists of an automatic high-precision drilling unit, a SPIROL Model CR Heavy Duty Pin Insertion Machine and a precision air-powered linear slide unit to move the assembly between the drill unit and installation station. The Model DP Drilling and Pinning Machine can drill holes ranging in diameter from 0.8mm-6mm (.031”-.250”) and is capable of insertion forces up to 8 kN (1,800 lbs).

Request for a quoteResults for

Installations - Import exportNumber of results

302 ProductsCountries

- Germany (302)

- Berlin and region (1)

- Bonn, Düsseldorf and North Rhine and Westphalia (152)

- Frankfurt am Main and Hesse (7)

- Hamburg and region (5)

- Hannover and Lower Saxony (6)

- Leipzig and Saxony (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (63)

- Saarbrücken and Saarland (4)

- Schwerin and Mecklenburg-Vorpommern (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (60)

- Weimar and Thuringia (1)

Company type

Category

- Metallurgy - machinery and installations (74)

- Industrial cabling (35)

- Plumbing installations (23)

- Screw cutting - steels and metals (20)

- Gas and oil - exploitation (11)

- Recycling - machines and installations (10)

- Gymnasiums - installations and equipment (10)

- Tennis courts and installations (10)

- Urban fixtures and installations (8)

- Vibrators, industrial - installations (7)

- Magnetic equipment (7)

- Electrical & Electronic Components (5)

- Solar energy - installations (4)

- Foundries - machinery and installations (4)

- Forges - machinery and installations (3)

- Connectors, electronic (3)

- Construction - Machines & Equipment (3)

- Concrete forms (3)

- Copper and copper alloys (3)

- Sensors (3)