- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- high-temperature pump

Results for

High-temperature pump - Import export

PROPACK DICHTUNGEN UND PACKUNGEN AG

Germany

Expanded natural Graphite in Purity 98 % – industrial grade or 99.85 % nuclear grade (chlorine content < 20 ppm) Temperature in steam Density min. 1.40 g/cm 3 Characteristics High cross section density Self lubrication and limited wear Dry running capability Coefficient of thermal expansion similar to steel Maintenance free and elastic, also under variable pressure Non ageing, high chemical resistance Attention! Precise tolerances and surfaces of application are requeste Operating range Pressure [p max]: 800 bar Temperature: t = -200… +550 °C pH: 0 - 14 Density: 1.80 g/cm³ Temperature in steam Density min. 1.40 g/cm 3 Main application Fittings Pumps (high temperature) Covers Valves Suitable for Valves and fittings of all Industries Approvals Oxygen BAM 200 °C/250 bar DVGW and KTW Variant Rings with integrated reinforcement or endcaps made from ANSI 316 Special quality TA Luft 300 with a leakage rate of 5.7 · 10 -3 mbar · l/(s·m) 300 °C Form of delivery ARF rings - endless,...

Request for a quote

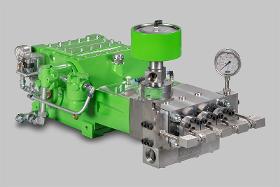

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

Melt pump for building up pressure in the polymer process. The series is the result of a complete revision of the core components used. The BOOSTER-AT is available with flange connections according to EN1092-1 and ANSI B16.5. Thanks to the new gear wheel geometries, differential pressures of up to 320 bar are possible with selected pump sizes. The new design is rounded off by the usual variety of different material combinations. Advantages: Higher efficiency, therefore Less temperature input into the polymer Wider viscosity range possible Larger volume flow range possible Increased safety against shaft breakage in case of overload due to new design

Request for a quote

WITTE PUMPS & TECHNOLOGY GMBH

Germany

The reliable booster pump for the polymer process. BOOSTER gear pumps from WITTE are used in the polymerisation process to increase the pressure of medium to high viscosity media. The hydraulically heated booster pump conveys very gently prepolymers and polymers, such as PET, PBT, PS, ABS and many others. Heating is by means of heat transfer oil or steam. The core components such as shafts and slide bearings come from the WITTE modular system. The booster pumps of the BOOSTER series are used wherever particularly high pressure is required for the process. High pressures are required for pelletising, fibre production or for spinning pumps, among others. The design of the BOOSTER booster pumps can be adapted to the needs of the plant and the customer's requirements.

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and solid parts or structural elements that can be used at temperatures up to 1.400 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% biosoluble — high temperature resistance — low thermal conductivity — high chemical resistance * — low weight — good tear resistance — high flexibility — easy processing — complicated geometries can be produced — recyclable * to achieve higher acid resistance, a special coating is required. Available from manufacturer. Application: Burner plant components, crucibles, thermocouple housings, coupling devices in continuous casting plants, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals, gasket in aluminium foundries, gaskets in blast furnaces, expansion joints, pipe insulation, catalyst insulation, repair work in the high temperature range.

Request for a quote

CBG COMPOSITES GMBH

Germany

High-temperature vacuum-formed products made from biosoluble ceramic fibres are lightweight and strong parts or structural elements that can be used at temperatures up to 1 .600 °C in air and in aggressive environments, including direct contact with liquid metals. — 100% natural — biosoluble — high thermal shock resistance — low thermal conductivity — high chemical resistance * — recyclable — low weight — good tear resistance — high flexibility — easy processing — harmless to health — complicated geometries can be produced * A special coating is required to achieve high acid resistance. Available from manufacturer. Fields of application: gaskets, crucibles, thermocouple housings, coupling devices in continuous casting plants, expansion joints, convex and flat gaskets in blast furnaces, channel elements of metal troughs, inlet device in the melting of non-ferrous and ferrous metals.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

High-temperature pump - Import exportNumber of results

6 ProductsCountries

Company type