- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- measuring instruments

Results for

Measuring instruments - Import export

BIZLINK ROBOTIC SOLUTIONS GERMANY GMBH

Germany

The advintec TCP tool calibration system calibrates the tool or fixture electronically in up to six dimensions. The robot program is automatically corrected by the measured variations and ensures that the tool always operates at the correct position. advintec TCP is a high-precision calibration system that can be used for all robot types and most robotic tools, making it independent of specific manufacturers. Correction takes place directly and automatically in the ongoing production process.

TECHNO-COMPOSITES DOMINE GMBH

Germany

Housing for satellite positioning devices TC designed and constructed a weatherresistant housing in a very small batch for highly sensitive satellite positioning measuring devices. Do you already have an idea of what we could do for you?

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Magnetic-inductive flow measurement allows the precise measurement of electrically conductive liquids such as sewage. Standard measuring values are the current flow and the accumulated pumping capacity (e.g. daily volume). The measuring signals are available either as 4 – 20 mA or impulse signals and can be transmitted to the data recorder for state recording and diagnosis or to the AWAcontrol control technology for pump control. Magnetic-inductive flow meters are reliable and economic compact units or installation in the pressure line and are available in two basic versions: Sensors for pipe installation with integrated measuring transducer and on-site display as a compact unit Sensors for pipe installation with separate measuring transducer. With this version, the measuring transducer can be located separately on the wall in the service building or as a fitted housing directly in the AWAcontrol control cabinet.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Closed pneumatic-mechanical switching system The sewage-resistant pressure bellows and the end membrane are connected via a pneumatic line routed in a protective tube. There is a plastic housing on the collecting tank of the sewage pumping station which contains 4 easily accessible micro-switches In addition, there is a manometer for continual filling level display located in the housing

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Redundant twin measuring system where there is a requirement for increased operational safety for sewage pumping stations (e.g. main pumping station) for municipal applications. Product features The twin measuring system HWAS-BN uses two mutually independent measuring systems which work in different ways. The analogue sensor HWAS for integration in the pump control unit is combined with the pneumatic-mechanical contact sensor system MB. If one of the two measuring systems fails, emergency control is automatically triggered by the other measuring system.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Redundant twin measuring system where there is a requirement for increased operational safety for sewage pumping stations (e.g. main pumping station) in building service engineering and for municipal applications. Product features The twin measuring system MWAS-BN uses two mutually independent measuring systems which work in different ways. The analogue sensor AS for integration in the pump control unit is combined with the pneumatic-mechanical contact sensor system MB. If one of the two measuring systems fails, emergency control is automatically triggered by the other measuring system.

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Pressure sensor for analogue filling level measurement Especially suitable for STRATE sewage pumping stations for municipal applications Supply voltage 24 V DC Output of an analogue measuring signal 4 – 20 mA Pressure ranges depending on tank height 0 – 200 or 0 – 400 mbar Safe at several times over-pressure Explosion protection according to ATEX

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Pressure sensor for analogue filling level measurement Supply voltage 24 V DC Output of an analogue measuring signal 4 – 20 mA Pressure ranges depending on tank height 0 – 50 / 200 or 400 mbar Safe at several times over-pressure Explosion protection according to ATEX

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Measurement using the impact pressure method Measuring range 0 – 0.5 mWS Connection via polyamide flange with quick-action elbow gland Enclosure rating IP 67 Including 5 metres of rigid PU hose (Ø 8 mm)

Request for a quote

INOEX GMBH

Germany

The AUREX ERS uses the measuring technique of the Electronic Rotating Scanner (ERS) principle. With this active-passive measurement, every point of the measured object is detected 100% in longitudinal and circumferential direction, so that even minimal tolerance deviations are detected. Coextruded layers can also be detected as soon as they are physically detectable by ultrasound. The AUREX ERS is complemented by the optional "Quality Check", a wall thickness error check. The "Quality Check" detects anomalies on the surface, in the material and on the inner surface of the pipe. Further advantages/features: — 100 % wall thickness measurement for pipe dimensions up to 630 mm in diameter — Electronic rotation up to 16,000 rpm — Evaluation of vertical and angular signals reflected from the tube by activating adjacent sensors — Highest measuring resolution and identification of smallest production variations

Request for a quote

INOEX GMBH

Germany

The WARP portable is a mobile, radar-based hand-held gauge for selective wall thickness measurement, specially designed for medium and large pipe extrusion as well as for sheets. The application possibilities are very flexible, whether as a quick centering aid in the start-up process, for final production control or as a stock control device. Not only wall thicknesses at pipe ends can be measured, but also the progression inside a pipe section or a sheet. The measurement itself is performed at the push of a button. The last 500 measured values including the measuring angle on the pipe as well as the time stamp are stored. Over 400 WARP portable sold speak for themselves. Other advantages/features: — Hand-held measuring device for wall thicknesses from 2 to 110 mm (depending on material) — Measured value log including measuring position on the pipe (last 500 measured values) — Intuitive handling — Splash-proof housing (IP54)

Request for a quote

INOEX GMBH

Germany

WARP 100 is an inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a gapless measurement. This is particularly important for pipes with high quality requirements, such as pressure or gas pipes. The maximum line speed for 100% coverage is up to 11.8 m/min. WARP 100 is available in three sizes and can be used for measurement in the diameter range from 25 to 630 mm. Measured variables such as wall thickness, diameter, ovality, eccentricity as well as process conditions (e.g. sagging) are precisely recorded, documented, and further used for automatic process control. Other advantages/features: — Measurement with 100% pipe coverage in diameter range from 25 to 630 mm (three sizes) — Wall thickness range from 2 up to 125 mm (depending on material) — Detection of thin sections within the tube — 100% documentation of production according to specifications

Request for a quote

INOEX GMBH

Germany

ECCO is the efficient solution for fast pipe centering. Especially for thick-walled large pipes, with low line speeds and high mass throughput, the start-up process is difficult, time-consuming, and associated with high raw material costs. ECCO makes it possible to measure the wall thickness distribution shortly after the pipe calibration. The ultrasonic sensors, which are mounted directly behind the calibration sleeve in the vacuum tank, are pneumatically and flexibly moved up to the respective pipe geometry after line start-up and adapted to the pipe. Further advantages/features: — Significant reduction of start-up scrap — Fast pipe wall centering — Fast reaching of product specifications after product start-up — Fast detection of product variations — Uniform wall thickness distribution — Suitable for PE, PVC, and PP with an outside diameter from 200 mm (wall thickness range PE from 8 - 140 mm, wall thickness range PVC and PP from 8 - 40 mm)

Request for a quote

INOEX GMBH

Germany

The WARP 8 is an inline pipe measuring system for wall thickness and diameter measurement at 8 points or 4 axes. It provides all important measurement data required for manual or automated process optimization and control. In addition to the short return-of-invest time, the system offers high measurement accuracy as well as process automation and documentation functions. The static sensors allow a high resolution of the measured values in the extrusion direction. Thus, process fluctuations are precisely recorded and visible, so that effects such as short-term fluctuations in output or backpressure effects during the sawing process can be detected and eliminated. Other advantages/features: — Diameter range from 60 to 1200 mm (five sizes) — Wall thickness range from 2 up to 250 mm (depending on material) — Short ROI period — Ideal for process optimization

Request for a quote

INOEX GMBH

Germany

The AUREX XXL is the solution for large pipes with a diameter of up to 3000 mm. The system works with 8 water-coupled ultrasonic sensors that can be pneumatically adjusted. This is possible without conversion in case of a change of dimensions. Minimum wall thickness tolerances are obtained via the downstream control loops of the weight per meter and thin point control and production is perfected. The better centering enables considerable material savings, especially for large pipes. Further advantages/features: — Production quality assurance by measuring and controlling wall thicknesses and diameter — Documentation of production — Material savings of up to 5% — Large measuring range — Proven measuring and control principles

Request for a quote

INOEX GMBH

Germany

The iXRAY solves almost all measuring, automation and documentation tasks for single and multi-layer pipes and hoses. Thanks to a precise spatial resolution and repeatabilities in the µm range, the system reliably generates exact measurement data. At high line speeds, the X-ray system - optionally two or three axes - delivers precise measurement results. The standard systems are available for pipe dimensions from 1 to 63 mm. The iXRAY series is user-friendly and the line operator only has to select the pipe, hose, or cable recipe to start the measurement. Other advantages/features: — Measurement of wall thickness distribution, inner and outer diameter, ovality and eccentricity — Up to 6 wall thickness values on the pipe or hose circumference — 3 diameter axes at 120° angle — High repeatability — High precision X-ray tubes with anode voltage up to 60 kV — Non-contact measurement, no seal, and no dimension-dependent accessories

Request for a quote

INOEX GMBH

Germany

The WARP CP is an inline measuring system with radar-based wall thickness sensors for detecting the various structures of a corrugated pipe. Outer and inner diameters, as well as the wall thicknesses of the bell, crest, liner, and valley can be resolved. The system is available for large, corrugated pipes with diameters from 300 mm. Since the corrugated tube has different structures, it is therefore necessary to assign the measurement data to the corresponding position on or in the tube. The WARP-CP algorithms do this automatically and prepare the data for the user in such a way that he receives different graphics and corresponding measurement data for each structure. Other advantages/features: — Non-destructive, contactless, and automated inline measurement of all relevant structures of the corrugated tube — No waste due to destructive measurement — Repair of critical thick and thin spots — Saving of material overweight in the end product

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INOEX GMBH

Germany

The AUREX MK is the complete solution for pipe dimensions from 0.5 - 400 mm. It enables compliance with the specified tolerances for wall thickness, eccentricity, diameter and ovality. Thanks to the combination of high-quality electronics with innovative measuring methods, up to 7 layers from 0.02 mm wall thickness can be evaluated. In addition to the standard measurement for control and visualization of the product, the "Fast Specification Check MK/AFM" is optionally available, which allows a fast wall thickness check. Since the AUREX MK does not completely cover the pipe at the circumference, this wall thickness check can be used, for example, to detect typical thin section rings caused by jerking of the produced pipe at the entire circumference.

Request for a quote

INOEX GMBH

Germany

The AUREX AFM measuring chambers are flanged directly to the outlet of the vacuum tank. With up to 24 sensors a reliable and precise ultrasonic measurement with a centric pipe guidance is guaranteed. The measuring chambers are available for a diameter range of 63 - 630 mm. The AUREX AFM performs wall thickness and diameter measurement in parallel according to the number of sensors. Optionally, the AUREX AFM can be equipped with the "Fast Specification Check MK/AFM", which enables a fast wall thickness check. Since the AUREX AFM does not completely cover the tube at the circumference, this wall thickness check can, for example, detect typical thin section rings, which are caused by jerks of the produced tube at the entire circumference. Further advantages/features: — Large measuring range with measuring range extension — Parallel measurement of wall thickness and diameter — Very robust mechanics — Separable adapter for easier seal change

Request for a quote

BLOWERDOOR GMBH

Germany

Fire safety is one of the areas where the use of BlowerDoor measurements is increasingly gaining in importance. In general, it is server rooms that are measured, where in the case of fire, this is quenched by special extinction gases. High-quality technology can thus be protected against damage from sprinkling or fire water. A prerequisite for the fire protection through extinction gases is an airtight room envelope.With the Minneapolis BlowerDoor measuring system and the FireProtection software, you can easily and accurately determine extinction gas holding times in accordance with ISO 14520 in rooms of angular volume.

Request for a quote

BLOWERDOOR GMBH

Germany

Bau.Tools BlowerDoor software has a new upgrade, offering professional thermographers even more: The differential thermography has been expanded to include sequential analysis, while the user interface has been newly designed at the same time to provide easy and intuitive usability. Bau.Tools BlowerDoor is now avalaible in English, German and French.

Request for a quote

BLOWERDOOR GMBH

Germany

The airtightness of outside windows and doors is an important criterion for achieving an airtight building envelope. The Window and Door Measurement System developed by BlowerDoor GmbH allows you to determine the joint permeability of building components in a simple and accurate way. On the basis of the measurement results windows and doors can be classified in accordance with EN 12207 (windows and doors, air permeability-classification).

Request for a quote

BLOWERDOOR GMBH

Germany

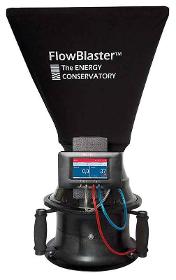

With a measuring range of 17 to 500 m³/h, the Minneapolis FlowBlaster has been especially designed for testing ventilation systems during residential and commercial construction. In combination with the measuring fan BlowerDoor MiniFan, it allows the precise measurement of the air flow at supply and exhaust air valves. Measuring the supply and exhaust air flow at the respective valves provides information as to whether the requirements have been implemented as designed. If the air flows measured at the valves deviate from the requirements, the ventilation system can be adjusted.

Request for a quote

BLOWERDOOR GMBH

Germany

The Minneapolis Micro Leakage Meter (MLM) Measuring System has been developed by the manufacturer The Energy Conservatory in close cooperation with BlowerDoor GmbH in order to guarantee the functionality of ventilation systems by conducting airtightness tests of the duct system. With a measuring range of 0.17 to 78.5 m³/h, the MLM is also suitable for testing building components as well as small and highly airtight clean rooms.

Request for a quote

BLOWERDOOR GMBH

Germany

To conduct airtightness tests in large buildings, simply combine several BlowerDoor fans (BlowerDoor MultipleFan): With up to three fans per door opening, Germany’s leading measuring system for airtightness easily masters even large air-flow rates! The BlowerDoor MultipleFan system consists of three BlowerDoor fans and two digital DG-1000 pressure gauges, and was developed for airtightness measurements of large buildings with an envelope area of approximately 7,000 to 36,000 m² or an internal volume of up to 440,000 m³. As a modular system, the MultipleFan system can be used for testing larger industrial and administrative buildings, but also for single-family homes and apartment buildings using one or two BlowerDoor fans.

Request for a quote

BLOWERDOOR GMBH

Germany

With a measuring range of 5 to 2,300 m³/h, our compact BlowerDoor MiniFan System is perfect for use in individual apartments or very airtight or smaller buildings.With the new DG-1000 high precision pressure gauge and the TECTITE Express 5.1 software included in the package, you can conduct highly accurate automated, semi-automated or manual BlowerDoor tests in accordance with ISO 9972 and European Standard EN 13829.

Request for a quote

BLOWERDOOR GMBH

Germany

Minneapolis BlowerDoor is a modular measuring system for airtightness. With its measuring range from 19 m³/h to 7,200 m³/h and the possibility to combine several BlowerDoor systems (MultipleFan), there are no limits to its use in Passive Houses, in newly constructed buildings, and in existing buildings and apartment buildings, as well as in industrial and administrative buildings. With the innovative DG-1000 high precision pressure gauge and the new TECTITE Express 5.1 software you can conduct highly accurate automated, semi-automated and manual BlowerDoor tests in accordance with ISO 9972 and the European Standard EN 13829.

Request for a quote

LABOM MESS- UND REGELTECHNIK GMBH

Germany

The ASEPTconnect Inline unit allows to install measuring instruments into pipes taking all requirements related to successful SIP and CIP procedures into account. The instrument connection is designed as Aseptic clamp connection per DIN11864-3, model A. Inline unit with aseptic clamp-connection per DIN 11864-3, model A (groove side), dead-zone free ■ Process connection: pipe ends or clamp-connection ■ Seals gap-free by means of an O-ring ■ Fast and accurate mounting of the devices ■ Various pipe diameters available ■ Hygienic design ■ Suitable for CIP or SIP procedures ■ Pipe ends suitable for orbital welding ■ Delta ferrite content < 0.5 %

Request for a quoteResults for

Measuring instruments - Import exportNumber of results

52 ProductsCountries

Company type