- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools for machining

Results for

Tools for machining - Import export

ECOROLL AG WERKZEUGTECHNIK

Germany

ECOROLL's OMEGA system combines skiving and roller burnishing for machining hydraulic cylinders and cylinder liners. While the OMEGA skiving head cuts the cylinder's inner surface to the exact size and form required, the roller head burnishes it. The simultaneous skiving and burnishing process has almost completely replaced honing as the alternative machining process, since it is much more economic and faster. Thanks to its modular design, customized tools can be configured based on pipe quality and machining length. Sometimes for various reasons, tubes have to be skived and burnished separately or both processes have to be carried out one after the other. Therefore, all SK skiving heads can be delivered also as separate tools. SK skiving heads are then used in conjunction with GZ roller burnishing tools. In the first pass the SK skiving head peels the cylinder, and in the second pass the GZ tool burnishes it smooth.

Request for a quote

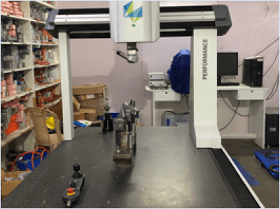

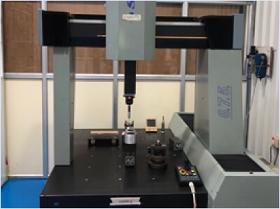

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Performance is the perfect solution for the most precise and fastest machining of your sheet material! The Performance is the flagship solution of the WiTEC machine family. A machine concept based on a FEM optimized design, built using premier precision components, and equipped with linear magnet motor technology, the Performance is able to achieve the highest levels of precision and speed, up to 80m/min! Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

Wissner’s highly dynamic GAMMA series is your HSC milling center for the most precise and fastest machining of your parts! Whether 3-axis, 4-axis or 5-axis – our modular concept allows customization to ensure your individual, machining tasks are achieved. The machine with a mono-block portal design is extremely compact and requires minimal space. The GAMMA series machines use Wissner’s FEM optimized machine frame with an exceptionally stiff and robust machine housing. The entire portal construction including side walls, the machine bed, and the traverse are built in one piece. Conical, tapered portal walls, a technology that Wissner initially introduced to this machine category, ensures a solid, vibration-free connection between the portal and the machine bed.

Request for a quote

WISSNER GESELLSCHAFT FÜR MASCHINENBAU MBH

Germany

WiTEC Basic - the perfect, allrounder machine for the most precise and fastest machining of your sheet materials! Equipped with an FEM optimized machine design, premier precision components, and using powerful Servo Technology, the WiTEC router is capable of achieving top milling speeds and delivering top precision results. Thanks to the combination of Wissner’s innovative and patented hold&press Technology and sophisticated Vacuum System, you can mill even the smallest parts all the way through the finishing cut-out! No need for any adhesive paper or foil, no need for leaving connector tabs, and no deburring or cleaning is necessary! The ready-finished parts will go directly from the machine table to the end customer!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Embossing punching is an important technique in the automated production of car parts, guided by robots. A laser system with a sensor harness measures the car body and its machining plane so that the embossing depth can be determined with maximum accuracy. The car body part is then embossed accordingly and all necessary holes are punched. Embossing punching is used for the fixture of headlights, bonnets, sliding roofs, boot lids and locks as well as wings. Our embossing punching machines are suitable for single-layer steel and aluminium sheet metal. This offer includes: • Embossing punching frame (assembly elements or components can be perfectly aligned to a mating part of different dimensions) • Handling: robot-guided via defined interfaces (mechanical, electrical, pneumatic) • Servo motor-driven Tool inserts and measurement are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

The multi-function unit is a universal C-shaped stationary machine designed for sheet metal utilising industries as a machine for every situation. In respect to working with sheet metal and profiles in aluminium, steel or stainless steel many demands are realised with the multi-function unit MFG 500/150 E. Accordingly the machine is used for clinching, self-piercing riveting, punching, pressing-in and embossing. However a new machine is not needed every time but merely an appropriate tool holder is inserted and the machine is ready for a further task. You can also choose from standardised tool holders or a custom-manufactured tool holder according to your needs. Required tools (punches and dies) and tool holders are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tools included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Domes produced with ECKOLD machines in automotive industry make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter). This offer includes: Dome embossing frame Embossings: 1 piece/stroke Embossing geometry: according to data set Drive: pneumohydraulic Mechanical interface: support stand Embossing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. We optionally offer hydraulic or servo motor drives as well as multiple embossings/stroke.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Small and easy to manoeuvre – Mobilformers MZ 30 for vessel flanging These portable forming pliers are the ideal tool for the flanging of cylinders, baffles and cones and can also be used for neck correction and general adjusting tasks. They are available with various quick-exchange tool inserts so that they can be configured to suit any forming task. The pliers are guided by hand along the workpiece. The ECKOLD Mobilformer MZ 30 has been developed for slightly thick sheets of 3.0 – 7.0 mm (steel) and 3.0 – 5.0 mm (stainless steel). Similar to the MZ 20, the MZ 30 is mainly used for the production of vessels and apparatures. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

For high force precision flanging tasks: Portable Kraftformers from ECKOLD This mobile C-frame is generally used for forming and adjusting tasks that require extra force. It is the perfect solution for the flanging of cylinders, baffles and cones as well as for flange repairs. Thanks to the exchangeable tool inserts, the Multiformer is a universal machine that can be configured to handle virtually any forming task. Its roller stops allow for accurate workpiece guidance through the machine. The portable Kraftformer MKF 130/16 is designed for the forming of steel sheets with a thickness from 4.0 to 10.0 mm and for 4.0 to 8.0 mm stainless steel. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Small and easy to manoeuvre – Mobilformers MZ 20 for vessel flanging These portable forming pliers are the ideal tool for the flanging of cylinders, baffles and cones and can also be used for neck correction and general adjusting tasks. They are available with various quick-exchange tool inserts so that they can be configured to suit any forming task. The pliers are guided by hand along the workpiece. The Mobilformer MZ 20 is the smallest machine of the ECKOLD Mobilformer ranges and therefore very easy to manoeuvre along the workpieces. The pliers are suitable for steel sheets of a thickness from 2 to 4 mm and for stainless steel of a thickness from 2 to 3 mm. The MZ 20 is mainly used for the production of vessels and apparatures. This offer includes a hydraulic drive unit HA 510. Tool inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, tool inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Seamclosing with hydraulic seamclosing pliers from ECKOLD: Perfect form-fitting joints in car body parts Seamclosing is a proven, form-fitting mechanical joining method used for car body parts, etc. The edges of sheet metal parts are folded around each other. This technique is employed in the automotive industry, for instance for the attachment of add-on parts. ECKOLD seamclosing machines are not only affordable and compact, but also highly efficient and therefore a great alternative to stationary presses and fully automated seamclosing stations. ECKOLD seamclosing equipment is the preferred option for prototype and small series production. This offer includes a hydraulic drive unit HA 510-F. Seamclosing inserts are not included in the scope of delivery. They must be chosen separately, based on the actual task. Contact us for a customised offer, inserts included!

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tools for machining - Import exportNumber of results

27 ProductsCountries

Company type