- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tools for machining

Results for

Tools for machining - Import export

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

Components and parts for machine builders,

Request for a quote

WIB SA

Switzerland

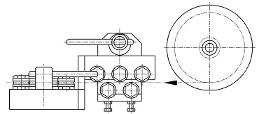

The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the ground “V” groove on the outer ring is machined and positioned precisely relative to the internal geometry. WIB only produces straightener roller bearings produced in this fashion, while many other producers machine the outer wire guide groove after assembly

Request for a quote

HOCHRAINER GMBH

Germany

Different systems can achieve the objective depending on product requirements: Machine tools for type VSMH rotary transfer machining (hydraulic) Machine tool for type VSMK rotary transfer machining (cam-controlled) Type NBM finishing machines for stamped, moulded, and cold extruded parts Our years of experience in complete machining of serial parts passes to the next generation in constructive and innovative cooperation.

Request for a quote

FÖHRENBACH GMBH

Germany

The rotary table combination RT3A100 consists of two directly driven rotary tables of the RT3A100 series. The B-axis has a swivelling range from approx. -10° to +110°; the C-axis can be rotated infinitely. The unit is driven by two integrated 3-phase synchronous motors. The drive guarantees highest dynamics and precision. An innovative clamping unit integrated in the housing guarantees high holding forces when the drives are switched off without position changes on the axes. By means of compressed are impact, the holding torque can be increased from 15Nm to 20Nm for special applications. The complete system is supplied as ready-to-connect unit.

Request for a quote

TOSYALI MAKINA A.S.

Turkey

1. It is a Single Leaf Chain Included in Two Standards EL chains are only included in the ISO standard, while AL chains are not subject to any regulation and have dimensions that vary between manufacturers. However, BL leaf chain is included in the international chain standard ISO4347 and BS29.8. 2. Offers Excellent Length Consistency BL series leaf chain has a consistent and reliable pitch and length because it consists of specific components. 3. It Has a Relatively Better Tensile Strength Rate BL series leaf chain has higher tensile strength and lower weight. The tensile strength rating can be up to 15% better than EL leaf chain, making it ideal for forklift masts and telescopic booms.

Request for a quote

SAMAG MACHINE TOOLS GMBH

Germany

KNOW-HOW & EXPERIENCE, COMMITMENT & IDEAS, RELIABILITY & FLEXIBILITY – SAMAG, MACHINE TOOLS FROM THURINGIA SINCE 1873! WE SEE OURSELVES AS DEVELOPERS AND MANUFACTURERS OF MACHINE CONCEPTS, FROM INDIVIDUAL MACHINES TO TURNKEY LINES. THE FOCUS OF OUR PRODUCTS IS ON MILLING AND DEEP DRILLING TECHNOLOGIES. Separated from the SAMAG Group, we have been independently continuing the tradition of mechanical engineering in Saalfeld / Thuringia as SAMAG Machine Tools GmbH since January 2020. With 140 employees, we draw on the experience of more than 145 years of machine tools for metal cutting. One of our strengths is the high level of technological solution expertise with which we help our customers worldwide achieve sustainable success. As an international machine tool manufacturer, our most important sales markets are the automotive industry, tool and mold making and mechanical engineering.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

It considers your process as a whole and transforms your business into lean production & We plan together with you the production technology you need for the entire facility in line with industry 4.0 requirements. In addition to all mechanical and electrical engineering, we provide complete mechanical, electrical and automation manufacturing with assembly service.

Request for a quote

TRINMAK MACHINE ENGINEERING AND INFORMATION TECHNOLOGIES INDUSTRY

Turkey

Cutting, bending, welding, machining, painting and assembly operations of specially designed chassis can be carried out within our company and the product is delivered to the end user in finished form.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Each our component is individually handled in complete care and tested with the latest measuring devices - Mitutoyo. Specialized in smaller productions has its own advantages. We individually devote ourselves to our partners. We support you by: - before production, we review the technical documentation and implement possible changes, - we have a larger amount of material in stock which guarantees us an immediate start of production and quick delivery of a new spare part, - all products are inspected, deburred and hand polished before release. The components are checked to ensure that they fit properly and that the external product is compatible. All dispatched products are functional and visually sophisticated. Which leads to more affordable and better quality of the end-product, and consequently greater satisfaction of our partners.

Request for a quote

BOGRAMA AG

Switzerland

The most universal and most sold model by far for the mid capacity range to 10,500 cycles/h. Simple operation from touchscreen Integrated controller for infeed hole punching Available in two working widths.

Request for a quote

BOGRAMA AG

Switzerland

High-performance drum feeder with low feed height for comfortable working. With a capacity of up to 20,000 cycles/h, the TA 20 is also deployed for the small folds of rotary printing sheets.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer table for inline configuration of BSR 550 Servo with machines interfaced upstream such as cross cutters and digital printing machines.

Request for a quote

BOGRAMA AG

Switzerland

Mobile transfer unit for inline operation with the BSR 550 Servo rotary die-cutter. For the perfect gripping of die cut products. Fitted with clocked air nozzles for the separation of inner cuts.

Request for a quote

BOGRAMA AG

Switzerland

Simple, cost-effective delivery with fixed height.

Request for a quote

BOGRAMA AG

Switzerland

The SAB 550 / 750 stream delivery is used for multiple-up production. Formats from A3 to 30 x 30 mm (minimum) can therefore be delivered in streams Round belt infeed for optimised product delivery Powered top belts with size-independent stream belt Preselection and total counters Motorised height adjustment Available in two working widths, optionally with stream belt extension to 2 meters.

Request for a quote

BOGRAMA AG

Switzerland

The BSM 750 Servo with integrated front trim lends the booklet its final form. Front trim, head and foot trim, and blank separation are performed in one operation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOGRAMA AG

Switzerland

"The compact and attractively priced BSR 550 basic is structured as an offline solution. It is designed specifically for users who want to produce small and medium runs economically and efficiently as well as for those for which the flexible connection options and technical features of the BSR 550 Servo have no priority. Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. To exchange the flexible dies the entire breakout and deliver unit is disconnected from the die-cutting area. Thus an optimal accessibility is guaranteed. After die-cutting the inner cuts are separated and the section grids deflected.

Request for a quote

BOGRAMA AG

Switzerland

This machine configuration is the most flexible variant. It can not only be combined with downstream but also with upstream equipment such as cross cutters, digital printing machines and folding machines. Products are fed individually to the punching area via register table and rotary punched by using a flexible die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The LS 1679 has been specially developed for press brakes. The basis for its high accuracy and repeatability is its precise glass scale and high-quality integral bearing. Thanks to the material of its steel track and steel roller bearing component pair it is very robust. There are many variants for connection to the machine frame, whereby the ball coupling offers the most degrees of freedom. Besides the standard resolution with 5 µm measuring step there is also a variant with 1 µm. For perfect mounting to the two C-columns there are variants with rightward and leftward cable outlets.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Exposed linear encoders are designed for use on machines and installations that require high accuracy of the measured value. Typical applications include: Measuring and production equipment in the semiconductor industry PCB assembly machines Ultra-precision machines High-accuracy machine tools Measuring machines and comparators, measuring microscopes, and other precision measuring devices Direct drives Our standard encoders are suitable for use in a low or medium vacuum. Encoders used for applications in a high or ultrahigh vacuum need to fulfill special requirements. Design and materials used have to be specially adapted for it. For more information, refer to the Technical Information document Linear Encoders for Vacuum Technology. The following exposed linear encoders are specially adapted for use in high and ultrahigh vacuum environments. • High vacuum: LIP 481 V and LIF 481 V • High vacuum: LIC 4113 V and LIC 4193 V • Ultrahigh vacuum: LIP 481 U

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Wireless signal transmission The signals are transmitted from wireless touch probes to the SE transmitter/receiver unit via • radio or infrared for the TS 460, • infrared for the TS 444, TS 642, TS 740. This makes these touch probes ideal for use on machines with automatic tool changers. The following transmitter/receiver units are available: • SE 660 for radio and infrared transmission; shared SE for TS 460 and TT 460 • SE 540 only for infrared transmission, for integration in the spindle head • SE 642 only for infrared transmission, shared SE for TS and TT The SE 660 communicates with the TS 460 and TT 460. The SE 540 and SE 642 can be used in any combination with the TS 4xx, TS 642 and TS 740 touch probes.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TS workpiece touch probes from HEIDENHAIN help you perform setup, measuring and inspection functions directly on the machine tool. The stylus of a TS touch trigger probe is defl ected upon contact with a workpiece surface. At that moment the TS generates a trigger signal that is transmitted either by cable, an infrared or radio beam to the control. The control simultaneously saves the actual position values as measured by the machine axis encoders, and uses this information for further processing.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TS workpiece touch probes fromHEIDENHAIN help you perform setup, measuring and inspection functions directly on the machine tool. The stylus of a TS touch trigger probe is defl ected upon contact with a workpiece surface. At that moment the TS generates a trigger signal that is transmitted either by cable, an infrared or radio beam to the control. The control simultaneously saves the actual position values as measured by the machine axis encoders, and uses this information for further processing. HEIDENHAIN touch probes are available in various versions for workpiece measurement on machining centers, milling, drilling, boring machines and CNC lathes.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The TT 160 and TT 460 tool touch probes aretouch trigger probes for the measurement and inspection of tools. The TT 160 features signal transmission by cable, while the TT 460 communicates wirelessly over a radio or infrared beam with the SE 660 transmitter/receiver unit. The disk-shaped probe contact of the TT is defl ected during physical probing of a tool. At that moment the TT generates a trigger signal that is transmitted to the control, where it is processed further. The trigger signal is generated through a wear-free optical switch that ensures high reliability. The probe contact is easy to exchange. The connection pin to the contact plate features a rated break point. This protects the touch probe from physical damage due to operator error.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The aluminum housing of a HEIDENHAIN sealed linear encoder protects the scale, scanning carriage, and its guideway from chips, dust, and fluids. Downward-oriented elastic lips seal the housing. The scanning carriage travels along the scale on a lowfriction guide. It is connected to the external mounting block by a coupling that compensates unavoidable misalignment between the scale and the machine guideways. For typical applications on manual machine tools such as milling machines or lathes, display steps of 10 µm or 5 µm are suffi cient. Such display steps are provided by the LS 300 and LS 600 series linear encoders with an accuracy grade of ± 10 µm per meter traverse.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

Linear encoders from HEIDENHAIN fornumerically controlled machine tools can be used nearly everywhere. They are ideal for machines and other equipment whose feed axes are in a servo loop, such as milling machines, machining centers, boring machines, lathes and grinding machines. The benefi cial dynamic behavior of the linear encoders, their high permissible traversing speed, and their acceleration in the direction of measurement predestine them for use on highly-dynamic conventional axes as well as on direct drives. The linear encoders with slimline scale housing are designed for limited installation space. Larger measuring lengths and higher acceleration loads are made possible by using mounting spars or clamping elements.

Request for a quoteResults for

Tools for machining - Import exportNumber of results

1,583 ProductsCountries

- Germany (789)

- Turkey (224)

- Italy (124)

- China (121)

- Switzerland (41)

- Austria (39)

- Portugal (29)

- United Kingdom (27)

- Czech Rep. (22)

- Netherlands (22)

- South Korea (19)

- Poland (18)

- France (17)

- Romania (15)

- Croatia (14)

- Slovenia (13)

- Spain (10)

- Sweden (6)

- Ireland (5)

- Belgium (4)

- Lithuania (4)

- Serbia (4)

- Ukraine (4)

- Belarus (3)

- Bulgaria (3)

- Russia (3)

- Slovakia (1)

- Taiwan R.O.C. (1)

- United States (1)

Company type

Category

- Machine tools, metal machining - parts and accessories (290)

- Machine tools - metal machining (287)

- Milling - machine tools (263)

- Industrial cutting machine tools (156)

- Cutting - machine tools (123)

- Adjustment - machine tools (82)

- Machine tools, cutting - parts and accessories (72)

- Machine tools, metal shaping - parts and accessories (72)

- Grinding - machine tools (71)

- Bending machine tools (69)

- Tools & Hardware (65)

- Drilling - machine tools (52)

- Sawing machine tools (51)

- Punching machine tools (41)

- Machine tools - metal shaping (40)

- Lapping - machine tools (37)

- Metal engraving - machine tools (33)

- Stamping - machine tools (30)

- Shearing machine tools (27)

- Embossing machine tools (21)