- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric controls

Results for

Electric controls - Import export

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

the economical alternative Replacement for STRATE 1DF2 and 2DF2 pump controllers suitable for connection to all STRATE fill level recording systems: contact-based or contactless the 2DF2 plus also handles dual level measurement: Sensor/pilot tube and sensor/contactor for outstanding operational reliability the current level and operating hours are always shown on the display

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

2DFmaster AWAcontrol control system for STRATE sewage pumping stations with two pumps each and an installed overall motor rating of 0.75 kW to 75 kW each. Particularly suitable for building services engineering and municipal applications (twin systems), offers outstanding ease of use and functionality of the AWAmaster technology also for pumping capacities over 4 kW. LCD plain text display Thermal and electrical motor monitoring Manual – 0 – Automatic functions Pump switch-off through switch-off point with run-on time Acknowledgement button Electronic monitoring of the motor current Forced switch-on, switchover and alternation of pumps Internal acoustic alarm Collective fault message potential-free and potential-bound Backwater alarm potential-free All settings and fault messages retained after power failure Operating hours counter High resistance to interference Simple operation Level recorded either by internal pressure transducer, external 4 – 20 mA probe or float switch

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

Compact control systems with micro-processor technology for controlling STRATE sewage pumping stations with two pumps each and an installed motor rating of up to 5,5 kW per pump. Particularly suitable for building services engineering (twin systems) and do not require a separate control cabinet. Compact control system AWAmaster 2 in plastic housing Ready for connection with 1.5 m cable and CEE plug 16 A, 5-pole Parallel operation of both pumps to cope with increased sewage volume (e.g. during heavy rain) LCD plain text display Thermal and electrical monitoring of the motors Manual – 0 – Automatic functions Pump switch-off through switch-off point with run-on time Acknowledgement button Electronic monitoring of the motor current Forced switch-on, switchover and alternation of pumps Variable graduated start-up (switch-on delay) Internal acoustic alarm Collective fault message potential-free and potential-bound Backwater alarm potential-free

Request for a quote

STRATE TECHNOLOGIE FÜR ABWASSER GMBH

Germany

The compact control system with micro-processor technology for controlling STRATE sewage pumping stations with one pump and an installed motor rating of up to 5,5 kW. Particularly suitable for building services engineering (single systems) and do not require a separate control cabinet. Compact control system AWAmaster 1 in plastic housing Ready for connection with 1.5 m cable and CEE plug 16 A, 5-pole LCD plain text display Thermal and electrical monitoring of the motor Manual – 0 – Automatic function Pump switch-off through time or switch-off point Acknowledgement button Operating hours counter Ammeter Electronic monitoring of the motor current Forced pump switch-on Variable graduated start-up (switch-on delay) Internal acoustic alarm Collective fault message potential-free and potential-bound Flood alarm potential-free All settings and fault messages retained after power failure (battery back-up not required) Reserve inputs for float switch, telecontrol module

Request for a quote

CUPASO DEUTSCHLAND GMBH

Germany

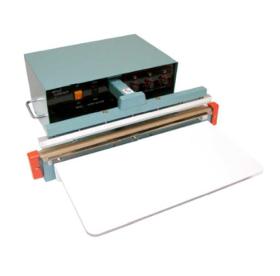

Electromagnetic sealing jaw type MS...IP for welding and sealing bags: - From PE - From PP - From soft PVC or polyamide Features: This sealing jaw has: - Adjustable welding time - Adjustable cooling time - Adjustable cycle time The jaw is controlled by an electric foot pedal.

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer accumulation table can store large quantities of glasses, bottles or tins. The products are pushed to the accumulation table if there is backlog. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle. In case of malfunction, the electrical control system activates the accumulation table based on sensor messages. After the malfunction ends, the stored products are automatically fed into the line. Technical data: —Chain width: up to 3,000 mm —Usable chain length: up to 20 m —Independent electrical control system Optional equipment: —Complete machine cover made of Makrolon with maintenance doors —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized switch divides the stream of products batch-by-batch and gently into several lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. Because the number and width of the lanes to be approached can be freely selected, the machine is suitable as product feed for palletizing machines or similar devices. Technical data: —Distribution: Number of lanes depends on the recipe —Distribution process during continuous flow of materials —Product gap: from 15 mm —Conveyor speed: more than 60 m/min. —Lane distance: depends on recipe —Complete machine cover made of Makrolon with maintenance doors —Independent electrical control system with congestion monitoring Optional equipment: —Loading and unloading belts —Infinitely variable width adjustment

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer discharging device for residual liquid permits emptying residual liquids from reusable bottles. Bottles with large quantities of residual liquid can be fed into the machine via a bypass. Cleaning occurs during continuous material flow. In addition to turning and cleaning, differences in height can be overcome at the same time. Technical data: —Conveyor performance: up to 60,000 units/h —Overhead track: up to 10 m —Difference in height: up to 10 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain optional equipment: —deflecting pulleys —motorized width adjustment —machine cover made of Makrolon or steel grid —electrical control system —loading and unloading belts —water lances for cleaning support of the cleated chain

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer revolving storage is the space-saving solution for storing solid, cube-shaped general cargo. The storage process occurs in cycle operation. The products move into the machine batch-by-batch and are stored vertically in compartments. The machine works according to the First In-Last Out principle. Technical data: —Length of batch: up to 3000 mm —Number of batches: up to 50 —Independent electrical control system Optional equipment: —Complete machine cover made of Makrolon with maintenance doors —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer aligner station is a solution if you have to feed glasses, bottles or tins aligned into a filling or labelling machine. By using high-performance product identification up to 350 products/min. can be identified and aligned in a continuous flow of materials. New products can easily be saved with the electrical control system's user-friendly operator interface. Technical data: —Conveyor performance: up to 350 items/min. —Installation length: 1500 mm (identification and alignment) —Infinitely variable adjustment to product height and width Optional equipment: —Camera housing against the influence of other light —High-speed camera for precise alignment even at high conveyor performance —Automatic discharging of faulty products

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer FIFO spiral buffer stores general cargo and bulk goods. The products are transported on a plastic mat conveyor chain. The chain is wound around one or two rotating towers in a spiral. The design of the machine permits storing unpackaged food. The machine works according to the First In-First Out principle. Technical data: —Chain width: up to 1,400 mm —Usable chain length: up to 1,000 m —Independent electrical control system Optional equipment —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer synchronized distributor divides the stream of products batch-by-batch and gently into two lanes. During the distribution process the products are not braked, so that functional reliability is ensured even at high speeds. The compact design permits simple incorporation into existing lines. Technical data Distribution: 2 lanes Distribution process during continuous flow of materials Product gap: from 5 mm Conveyor speed: more than 60 m/min. Lane distance: 110 mm, 130 mm Complete machine cover made of Makrolon with maintenance doors Independent electrical control system with congestion monitoring Installation length: 1200 mm Optional equipment Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer overhead conveyor is used for discharging or transferring products. Distribution occurs in cycle operation and across the direction of transport. Depending on the use case, it is attached to existing machines to save space, or is set up in a free-standing housing. Even large distances can be overcome with the machine. Technical data: —Distribution: 2 lanes —Distribution process in cycle operation —Lane distance: up to 3000 mm —Complete machine cover made of Makrolon with maintenance doors Optional equipment: —Independent electrical control system with congestion monitoring —Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

Gronemeyer lane bridging increases the accessibility of the various machines in a filling and packaging line. The gripper technology permits space-saving bridging of roads or pedestrian walks. Even large spans can be realised. Technical data: —Conveyor performance: up to 60,000 units/h —Crossing width: up to 6 m —Crossing height: up to 3 m —Product weight: up to 40 kg —Product width: 20 - 450 mm —Solid steel construction in painted or stainless-steel version —Manual width adjustment —Automatic tensioning station for the cleated chain —Central lubrication system for the cleated chain Optional equipment: —Moving deflecting pulleys in the curves to reduce wear on chains and slide rails —Motorized width adjustment —Complete machine cover made of Makrolon or steel grid with maintenance doors —Independent electrical control system with congestion monitoring —Loading and unloading belts

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer depalletizer is an economical alternative to a completely automatic machine. It is used when processing small to mid-sized numbers of items. An individual arrangement of depalletizers lets one person operate several machines. Easy operation allows for a short training period for new personnel. Technical data: —Use of EURO pallets (1200x800 mm) or special sizes (1200x1000 mm) —Pallet height: up to 2250 mm —Pallet weight: up to 1000 kg —Depalletizer performance: up to 64 layers/h for 8 pallets —Independent electrical control system Optional equipment: —Unloading belts —Accessible platform according to customer request

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer switch divides the stream of products into two or more lanes during continuous operation or in cycle operation. You can select either a pneumatic or an electrical drive. The pneumatic drive is characterized by a good price-performance ratio. The electrical drive allows you to divide the stream of products into more than two lanes. Technical data: —Distribution: 2 lanes —Distribution process in cycle operation —Lane distance: up to 250 mm —Pneumatic drive Optional equipment: —Independent electrical control system with congestion monitoring —Loading and unloading belts —Infinitely variable width adjustment —Combination with gripper technology for distribution during continuous operation —Electrical drive for distribution to multiple lanes —Complete machine cover made of Makrolon with maintenance doors

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

Gronemeyer Heliflex storage systems store general cargo that is up to 400 mm wide and 160 mm high. The products are transported on a plastic Heliflex chain. The chain is wound around two rotating towers in a spiral. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle. Technical data: —Chain width: up to 400 mm —Usable chain length: up to 1,000 m —Independent electrical control system Optional equipment: —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAMPMANN GMBH & CO. KG

Germany

Features — Particularly beneficial in modern buildings with large windows — With natural convection for complete room heating, supplementary heating and/or cold air screening — Adaptation of length by trench extensions provided by empty trenches or by coupling standard lengths together — Convenient surface- or flush-mounted electrical controller Tailor-made Your customer gets the thing you appreciate about Kampmann: individual made-to-fit trenches for all façades. Regardless of whether you need mitred corners, curved trenches, column cutouts etc. Our trenches are also available for floor-mounting or semi-recessed. Uses — Hotels/motels — Sales rooms and showrooms — Office and meeting rooms — Residential areas and conservatories — Restaurants and cafés

Request for a quote

ASSMY & BÖTTGER ELECTRONIC GMBH / A+B ELECTRONIC

Germany

As a manufacturer of control cabinets, we are always at your side. We process standard cabinets as well as special designs for our customers. We take care of construction and wiring plans directly according to customer specifications, as well as the mechanical processing, the construction and the wiring of the control cabinets. After the actual construction, we also carry out an electrical test and insulation tests. Upon delivery, you will receive the customer-specific labels and accompanying documents. Your advantages with A + B Electronic -Switch cabinets directly according to your specifications -We are not just a service provider, but a technology partner: A + B Electronic thinks your project with you and together we can bring it to series production successfully

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

The main characteristics of the forced ventilation unit are short assembling measures. The ventilations are static and dynamically balanced, thus, of a high balance quality. The diameter, the length as well as the side punchings can be made to customer´s requirements.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

This forced ventilation series offers a wide voltage range of 400 to 575 Volt three-phase in IP 66 Made in Europe. Forced vent. - Motor optionally available in three versions. Mb 1F for standard forced ventilation with drive motor in aluminium, in IP66, insul. Class F. Mb 1G for all special versions, drive motor in cast iron, IP66. Special versions further available in insul. Class H, IP67, special voltage etc. Mb 1H with UL/CSA certified drive motor in aluminium, IP66, insul. Class F.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

Forced Ventilation Units Forced Ventilation Units type MW in IP 66 with axial ventilation fan to ensure a low run at a simultaneously higher output. These units can be operated at a higher ambient temperature of max. 60 °C.

Request for a quote

KURT MAIER MOTOR-PRESS GMBH

Germany

This forced ventilation series offers a wide voltage range of 220 to 275 (+-5%) Volt single-phase respectively 380 to 480 (+-5%)Volt three-phase in protection class IP 66 The very high stiffness and stability in connection with our flexible assembly possibilities for the extensions and the wide electric field of application offers you a cost-effective, technically high-quality solution for your motors .

Request for a quoteResults for

Electric controls - Import exportNumber of results

24 ProductsCountries