- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- furnaces

Results for

Furnaces - Import export

WIGTEC FISCHEREDER KG

Germany

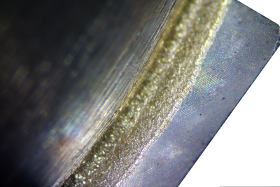

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The ExoFlex™ line of exothermic gas generators is designed to generate lean or rich exothermic gas. The generator includes automatic output turndown to 20% of the generator capacity with little loss of efficiency using the patented, maintenance-free ExoInjector™ gas mixing system. Thanks to a patented fuel injection technology that utilizes electronic flow measurement and precise ratio control, ExoFlex™ consistently provides the ideal mixture for high quality gas production. Another innovative design feature is the trim control input with programmable control range for precise generator control, which also eliminates the need for extra meters or valves. The ExoInjector™ easily replaces existing carburetor/pump designs for a significant reduction in process costs.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The advanced EndoFlex™ endothermic gas generator combines the patented EndoInjector™ fuel injection generator control system with the high-efficiency ReactionCore™ technology to lower operation and maintenance costs associated with producing high quality endothermic gas for your heat treatment furnaces. The generator is equipped with the latest sensors to monitor dew point, unreacted methane, and energy consumption. The touchscreen interface provides easy access to review generator operations, and the integrated paperless chart recorder tracks generator performance to meet production auditing requirements. ReactionCore™ technology is a proprietary generator design that replaces a single large retort with several smaller centrifugally-cast retorts to significantly increase the surface area, improve the heating efficiency of the reaction chamber, and reduce the heating energy required for the production of endothermic gas. In addition, the smaller retort design significantly...

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

FEATURES & BENEFITS • Direct reading of dew point with calculated % carbon • Direct reading digital display of process dew point • Designed for use in heat-treat applications • Equilibrium %C computed with entered process temperature. Feature provides cross check for oxygen probe systems • CQI 9 compliant furnace atmosphere measurement • No interpretation errors • Short response times, even when moving between a high and low dew point process • Easy-to-use, simple operation, operator training in minutes • Rugged capacitive sensor • Long life rechargeable battery • NIST traceable calibration • Calibration certificate supplied with factory calibration

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 455 is a ½ DIN powerful controller designed to monitor, control and record a variety of heat treating processes. Used in new furnaces as well as for refurbishing or updating existing systems, it is ideal for nitriding, nitrocarburizing, carburizing, carbonitriding, hardening, tempering and vacuum furnaces. FEATURES • color touch-screen interface • built-in chart recorder function • calculates variables such as % carbon, dew point, or millivolts, and percent oxygen • stores up to 200 19-step recipes • direct drop-in replacement for Marathon Monitors’ CarbPro, DualPro, MultiPro, and Carb PC • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750, & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

The Protherm 470 controller is designed to monitor, control, record and archive heat treatment processes running in a furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • ½ DIN multi-loop embedded programmer with a color display and turn-and-push knob navigation • Up to 32 programmable PIDs included • built-in calculators for real-time carbon and/or nitrogen diffusion, and hardness profile • mathematical model for calculating atmospheric parameters • integrated web server for browser-based remote access • works with internal and/or external I/O’s • suitable for all types of processes such as nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • standard connectivity allows for integration with SCADA systems • for compliance with CQI-9, AMS 2750 & AMS 2759/10-12

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Protherm controllers are universal configurable programmers that monitor, control and record processes running in a single furnace or simultaneously in multiple chambers. They are configurable for various types of batch and continuous furnaces. Installations are done on new or refurbished furnaces and are used for updating existing systems. FEATURES • Up to 32 PID control-loops to regulate parameters such as temperature, furnace pressure, atmosphere parameters (e.g.: carbon potential, nitriding potential and oxygen potential) • Real-time monitoring of jobs at all stages • Process parameters configured with alarm limits • Online diffusion calculation to control the process using required target values (e.g.: case depth, surface carbon content) • Up to 999 treatments/templates can be created and modified • Integration with SCADA systems • For all types of processes: nitriding, nitrocarburizing, carburizing, carbonitriding, plasma and vacuum • For compliance with CQI-9, AMS 2750 &..

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

In-line conveyor ovens: Pallets pass through the oven one after the other. Automatic batch ovens: The oven is charged with pallets while kept at a temperature below the gelation temperature. After the last pallet has been loaded, the temperature cycle is started for the whole lot. The oven is emptied in a rapid process after the complete temperature profile has been run through. Stack ovens: Pallets are loaded into the oven. When each row has been filled, all the rows of pallets are lifted up by one level. When one row of pallets has reached the uppermost position of a temperature range, it is pushed into the next temperature zone and from here is lowered down in fixed time cycles and unloaded. Serpentine conveyor ovens: Pallets are loaded into the oven in fixed time cycles and pass through the individual temperature zones.

Request for a quote

REINHARDT GMBH

Germany

Since decades, Reinhardt ovens “Made in Germany” are working day by day all over the world and are estimated by their reliability and long life time. Adapted to your requirements, a Reinhardt oven delivers the best results that are completely designed to your production process. In the temperature range up to 650° Celsius Reinhardt offers the best solutions for almost all requirements, for heating, tempering, drying, hardening, etc. all designed to your space conditions. All heating technologies, from electrical, direct or indirect gas, oil can be applied. Together with the customer, the Reinhardt industrial ovens are integrated into the production flow. In a classical batch oven, hood oven or pass through oven all thermal processes can be applied with the highest accuracy. Requirements such as lifting doors, charging carrier, transport and handling systems can be easily applied.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq TP6 is the perfect solution for the most demanding high temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Its robust software options also allow you to read information from the data logger in real-time with the optional Radio Frequency (RF) system and USB/Bluetooth connection options. • Available in 10 and 20 channel configurations and two case styles • Water resistant (IP67 rated) • ATEX certified version available, allowing for safe operation in Zone II classified areas • Communication via USB or Bluetooth • Real time telemetry via USB, RF telemetry and Bluetooth* • Alkaline, NiMH and Lithium battery options • Compatible with the Datapaq Insight™ for mobile application

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Furnace Tracker Sealed Quench Systems from Fluke Process instruments feature the Datapaq TP6 data logger, a sealed & quenchable thermal barriers from the SQ00 range, thermocouples and our intuitive Insight™ software to create a complete solution. This system is designed specifically for the aluminum solution heat treatment process. The system features a fully sealed design incorporating a pressure relief system, which allows for the most efficient insulation and enables the system to travel through every stage of your process. It can also be used in other solution heat treatment processes up to 900°C (1652°F) such as that for Titanium. Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ Software, you can display information from the data logger

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Vacuum Heat Treatment System from Fluke Process Instruments features the Datapaq TP6 data logger, choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Insight™ software to create a complete solution. The Furnace Tracker Systems that include the Datapaq TB45 series of thermal barriers can operate in temperatures up to 1050°C (1922°F) and the TB46 series can withstand temperatures of up to 1200°C (2192°F). Both are designed for use in vacuum and carburizing applications and can operate in pressures up to 20 Bar (290 PSi). Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker for Metals Heat Treating from Fluke Process Instruments features the Datapaq TP6 data logger, choice of thermal barrier (Datapaq TB40 or TB49), thermocouples and our intuitive Datapaq Insight™ Software to create a complete solution. Furnace Tracker Systems that include thermal barriers from the Datapaq TB40 Series are designed for use in conveyorized or batch furnaces, operated up to 800°C (1472°F). For processes at higher temperatures, the Datapaq TB49 Series features floating plate technology and more exotic materials, which enable use up to 1050°C (1922°F). Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ Software, you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Specialty Profiling Systems from Fluke Process Instruments features the Datapaq TP6 and Datapaq DP5 data loggers, hundreds of application specific thermal barriers, thermocouples and our intuitive Datapaq Insight™ Software to create a complete solution. These specialty systems enable through-process temperature profiles to be obtained in processes where long trailing thermocouples are not an option. Each thermal barrier is designed with a specific application in mind to provide the optimum solution for your process. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution. For more information, visit our customized profiling systems page. Data loggers The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Systems for Glass Tempering and Bending from Fluke Process Instruments feature the Datapaq DP5 data logger, low height thermal barriers from our TB75/TB77 range, thermocouples and our intuitive Insight™ Software to create a complete solution. This solution is optimized specifically for the glass tempering process, where the height at the furnace entrance is typically very limited. The system’s unique thermal barrier design includes an exterior ceramic coating to ensure there is no metal contact with furnace rollers. This solution ranges from 29 to 60mm (1.14 to 2.36 in.) high and can be used in temperatures up to 1000°C (1832°F). Data Logger The Datapaq DP5 is the perfect solution for low-height applications like glass tempering due to its size, which can be as low as 11.7mm (0.46 in.) and as narrow as 57 mm (2.24 in.). Once combined with the Datapaq Insight™ Software, you can display information

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Rotational Furnace Tracker Systems from Fluke Process Instruments features the Datapaq TP6 data logger, a rotational evaporative barrier, thermocouples and our intuitive Insight™ Software to create a complete solution. This system is designed to be fitted to the end of test logs or inside pipes to travel through your process measuring data from the product and can be used in applications up to 1000°C (1832°F). Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections. Available in 10 and 20 channel configurations and two case styles Water resistant (IP67 rated) Communication via USB or Bluetooth

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker System from Fluke Process Instruments features the Datapaq TP6 data logger, choice of phased evaporative thermal barriers, thermocouples, and our intuitive Insight™ Software to create a complete profiling solution. Each furnace tracker can be detailed to fit into a cut out of the slab or, if height permits, they can be placed on the slab. Meanwhile, systems for billet profiling are designed to mount to the end of the billet. Data Logger The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections. Available in 10 and 20 channel configurations and two case styles Water resistant (IP67 rated) Communication via USB

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The Datapaq Furnace Tracker Temperature Uniformity Survey (TUS) System from Fluke Process Instruments features the choice of data logger (TP6 or XDL12), choice of thermal barrier (TB45 or TB46), thermocouples and our intuitive Temperature Uniformity Survey (TUS) Insight™ Software package to perform accurate in-process product thermal profiling while verifying conformity to all required specifications, including the AMS2750 standard. Data Loggers The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections. Available in 10 and 20 channel configurations and two case styles Water resistant (IP67 rated) Communication via USB or Bluetooth

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The ThermoView TV30 thermal imaging camera provides a rich feature set of automation and control capabilities along with the expected durability to meet the demanding industrial applications that FPI product need to survive in. TV30 can interface directly to factory automation equipment, 3rd party software such as Labview, or Fluke Process Instruments ThermoView software. By incorporating a built-in I/O for automation applications in a small foot print, you can expand your field of view by providing continuous infrared images, recording, and actionable analytics right at your fingertips. To meet the factory automation needs of today, TV30 cameras utilize edge technology to provide analytics calculations and on board I/O, multiple fieldbus protocol capabilities to interface to a variety of factory automation equipment, along with high-speed GigE vision capability for the most demanding applications.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ Furnace Tracker systems offer accurate and reliable in-process temperature profiling and surveying solutions for a wide variety of demanding high temperature heat treatment processes in the glass and metalls industries and in aluminum manufacturing (Annealing * Brazing * Homogenizing * Decorating * Tempering * Forming * Frit Sealing * Normalizing * Billet Reheating * Slab Reheating * Pressure and Vacuum Processes). TB4000 Series Thermal Barriers: Rugged 304 stainless steel construction Microporous insulation provides the best thermal protection of any known material Various heights available to meet limited clearances TB4900 Series Thermal Barriers Exceptional durability and thermal resistance Outstanding resistance to oxidation and distortion One way lid and base alignment avoids thermocouple damage DATAPAQ temperature profiling systems comprise high-accuracy industrial-strength data loggers, thermocouples, thermal barriers, and analysis software.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Type K 1.5mm (0.05in) ⌀ mineral insulated for all general furnace profiling applications Nicrobel sheath protects against electrical noise and furnace atmosphere Type K 3.0mm (0.1in) ⌀ mineral insulated for high-temp steel reheat applications Larger ⌀ less prone to shunt errors, while retaining flexibility for setup Type K “Nextel” insulated, best for low-temp applications or where fast response from open junction is needed No resistance to furnace atmosphere or electrical noise Type N 2.0mm (0.07in) ⌀ mineral insulated for furnace survey applications (TUS compliant with AMS 2750D) Calibration services for AMS 2750 and CQI-9 requirements Less susceptible to oxidation, possible re-use Type K high-temp glass fiber insulated probes for auto windscreen forming applications Used with CS2035 probe kit Type K heavy-duty PTFE insulated probes For use with pressure thermal barrier in ‘wet’ or dry autoclave applications

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

Datapaq Furnace Tracker temperature profilers are available for all kinds of thermal processes in the metals, steel, and glass industries. The systems based on the Datapaq DP5 data logger are designed for short and medium duration processes. The portfolio includes a comprehensive range of high-accuracy, industrial-strength DATA LOGGERS with six or 12 measurement channels, various THERMAL BARRIERS that protect the electronics from heavy-duty process conditions, the Datapaq Insight ANALYSIS SOFTWARE, and a selection of fast-response, high-temperature type K or N THERMOCOUPLES. Designed to ensure minimum running costs, DP5 loggers store up to 10 profile runs before download to a PC. The built-in harsh-environment radio transmitter provides real-time data from within the process, speeding up fault-finding and process optimizations. The loggers can be recharged from flat to usable in just five minutes. A full charge via high-speed USB takes only 90 minutes and can provide 20 profile runs.

Request for a quote

FLUKE PROCESS INSTRUMENTS GMBH

Germany

DATAPAQ TP3 data logger * 10 or 20 thermocouple channels * Temperature range: -100 °C – 1370 °C/-148 °F – 2498 °F * Sample interval: 0.1 sec – 50 min without telemetry; 1 sec – 50 min with RF radio data transmission * Memory: 3.6 million data points * Robust stainless-steel machined case * High logger accuracy: ±0.3°C (±0.5°F) Comprehensive thermal barrier range for * Heat treatment and TUS * Vacuum carburizing and vacuum heat treatment * Aluminum solution treatment and age hardening * Steel slab and billet reheat * Controlled atmosphere brazing * Aluminium vacuum brazing Specialized software for TUS applications is trusted by hundreds of our customers to meet the stringent requirements of AMS2750E and CQI-9 certifications. Fluke Process Instruments offers a wide variety of PTFE, glass fiber or mineral insulated thermocouples to withstand harsh environments and high temperatures, conforming to the highest standards and providing the most accurate data possible.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For temperatures up to 450 °C. High-temperature furnaces Tempering furnace for car chassis stabilisers Previously cold-formed workpieces, e.g. stabilisers, are heated up in the tempering furnace at circulating air temperatures of up to 450°C and maintained at this temperature for an adjustable dwell time. This tempering increases toughness and dissipates residual stresses. Preheating furnace for frying pans and roasting tins Pan blanks are heated up to a temperature of approx. 390 °C and burnt free of all grease and oil residues. Enamelling furnace for frying pans and roasting tins The PTFE coating sprayed beforehand onto the frying pans is baked on at a temperature of approx. 450 °C. PTFE is used as a non-stick coating for frying pans and cooking pots on account of its low surface tension and good heat resistance. Chamber enamelling furnace for aluminium sheet metal forms Baking on of the single or multi-layer PTFE coatings at approx. 450 °C.

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your annealing / bright annealing / normalizing operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Annealing / Bright annealing / Normalizing control Solution is supplied with a PROTHERM controller and either an AccuCarb® LTA probe or FurnaceDoctor® FX analyzer or with Protherm ActivePLC™, FurnaceMeter™, AtmoSense™ and UPC oxygen probes for a variety of furnace types. FEATURES • AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Latest achievements in process control • Cost-effective module configurations * depending on the options chosen

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your annealing / bright annealing / normalizing operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Annealing / Bright annealing / Normalizing control Solution is supplied with a PROTHERM controller and either an AccuCarb® LTA probe or FurnaceDoctor® FX analyzer or with Protherm ActivePLC™, FurnaceMeter™, AtmoSense™ and UPC oxygen probes for a variety of furnace types. FEATURES • AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Latest achievements in process control • Cost-effective module configurations * depending on the options chosen

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your annealing / bright annealing / normalizing operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Annealing / Bright annealing / Normalizing control Solution is supplied with a PROTHERM controller and either an AccuCarb® LTA probe or FurnaceDoctor® FX analyzer or with Protherm ActivePLC™, FurnaceMeter™, AtmoSense™ and UPC oxygen probes for a variety of furnace types. FEATURES • AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Latest achievements in process control • Cost-effective module configurations * depending on the options chosen

Request for a quote

UNITED PROCESS CONTROLS GMBH

Germany

Our modular control packages are customized to significantly improve your vacuum heat treat operations, meet industry standards requirements and ultimately provide you with precise and reliable process control. We offer compact, fully automatic modules for new installations or retrofits. Each solution consists of a cost-effective module or combination of modules delivered with state-of-the-art equipment and backed by our extensive technological expertise. Vacuum Control Solution is supplied with a PROTHERM programmable controller and optional multiple load thermocouple inputs for soak guarantees. Interfaces to popular vacuum gauges. FEATURES • Full compliance with AMS 2750, CQI-9, NFPA 86-C, NADCAP* • Expanded recipe control including automatic leak test cycles • Guaranteed soaks based on multiple work thermocouples • Recipe control of partial pressure setpoints, guaranteed soak, ramp rates, events and quench gas selection • Built-in uniformity survey capability • Temperature...

Request for a quoteResults for

Furnaces - Import exportNumber of results

56 ProductsCountries

Company type

Category

- Heat treatment furnaces (12)

- Infrared tubes (9)

- Gas and oil - exploitation (4)

- Temperature sensing devices (4)

- Ovens, kilns, furnaces and hearths, industrial (3)

- Metallurgy and iron and steel industry - machinery and installations (2)

- Industrial furnaces (1)

- Furnaces, ovens and kilns, electric (1)

- Smelting furnaces (1)

- Offshore construction (1)

- Oiling - machines and systems (1)

- Steel & Metals (1)

- Vacuum cleaners - industrial (1)