- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- furnaces

Results for

Furnaces - Import export

WIGTEC FISCHEREDER KG

Germany

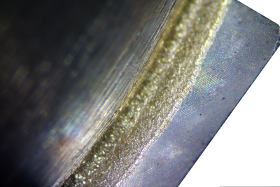

In the WTH 200.2, the following materials can be reliably brazed with active materials in a high vacuum. PCD (polycrystalline diamond) MKD (monocrystalline diamond) CVD diamond (chemical vapour deposition) PCBN (cubic boron nitride) and Hard metals as well Ceramics In the high-vacuum furnace WTH 200.2, our customers manufacture indexable inserts, dressing wheels, rotating tools and turning tools with blades made of natural diamond or MKD for polish turning. The vacuum brazing is flux-free. In the so-called active brazing process, titanium allows wetting of the surfaces. While cemented hard metals can also be inductively brazed, diamonds, CVD and ceramics must be actively brazed in a vacuum. When brazing PCD and PCBN, not only the hard metal substrate but also the PCD or PCBN layers are wetted.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

High-vacuum heat-treatment furnaces with integrated pressing unit and power-regulated resistance heater elements (Hot Press). Used for diffusion bonding and forming processes under high vacuum conditions as well universal use for thermal treatments and processes where particularly demanding requirements and sophisticated materials are involved.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

The SSH is a standardized vacuum-pressure sintering furnace for economic production of hardmetal (cemented carbide) parts. It combines the universal application of dewaxing (debinding), vacuum-sintering and isostatic pressing up to 60 bar overpressure in one process. Based on PVA TePla's leadership in production of Sinter HIP furnaces for hardmetal applications, the SSH furnace gives you a most affordable and economic access to this leading technology. Applications: Dewaxing (Debinding), vacuum-sintering, isostatic pressing Customer Benefits: • High product quality by excellent temperature homogeneity • Elaborated safety system for reliable and full-automatic operation • Short dewaxing and cooling times • Short installation and ramp-up times, all pre-tests and qualifications done at PVA site • Proven design and performance • Short delivery time due to pre-production • High cost effectiveness • High energy efficiency • Low gas consumption

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Plasma heat treatment, especially pulse plasma nitriding and pulse plasma nitrocarburizing is used for surface treatment of work pieces for protection against wear. For the treatment by plasma, the parts have to be placed in a vacuum vessel and are electrically insulated from the case. At a pressure of 50 - 500 Pa, a pulsed electrical D.C. voltage of several hundred volts is used between work piece and vessel, whereby the workload is switched cathodically. The ionizing of the remaining gas in the vessel results in a glow discharge. The electrical, positive ions are moving towards the work piece and impact with high kinetic energy. During this process at the surface the following happens: • sputtering, cleaning and activation of the surface • heating of the work piece by absorption of kinetic energy of ions • reactions of highly active ions with elements in basic work material • diffusion of elements -which are to be found in gas- into the work piece

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

Heat Treatment furnaces MOV are ideal for the treatment of sophisticated materials if high temperatures and an absolutely clean hydro-carbon free atmosphere are required. Due to the ultrahigh vacuum atmosphere as well as the extreme temperature homogeneity and the fully automatic process the furnaces are especially suitable for the economic application in industrial and medical productions, i.e. for brazing of vacuum interruptors, parts of x ray tubes, heat exchangers, parts used in the medical and aerospace industry. Applications: MOV furnaces are universally applicable if heat treatment with particularly high requirements in respect of cleanliness for exacting materials is involved, for example: • Degassing of electric or radiation tube components • Bright- and stress-free annealing of high-temperature alloys • Sintering of high-melting and heavy metals such as tungsten • Production of high-quality fluxless braze joinings of steels, steel-ceramics and many other materials.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

OV heat treatment furnaces are high performance most efficient furnaces with a wide working-temperature and application range. Due to the compatibility with all kind of process gases and the fully automatic process runs they are especially suitable for the economic application in industrial productions for example to produce hard metals or the cleaning and purification of graphite. Applications: • operating temperatures up to 1.100 °C: heat treatment, brazing, reduction, degassing and debinding • operating temperatures up to 1.350 °C: heat treatment, brazing, degassing, debinding and sintering • operating temperatures up to 1.600 °C: debinding and sintering of hard metals • operating temperatures up to 1.800 °C: sintering of non-oxydic ceramics • operating temperatures up to 2.000°C: CVD- and pyrolytic processes, degassing, cleaning, sintering • operating temperatures up to 2.400 °C: CVD-processes, degassing, cleaning • operating temperatures above 2.

Request for a quoteResults for

Furnaces - Import exportNumber of results

8 ProductsCountries

Company type