- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- equipment machine

Results for

Equipment machine - Import export

GEPPERT RÜHRTECHNIK GMBH

Germany

Rigid stand for wall-mounting for tank volumes from 100 l. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching agitator elements. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The stand WRW is available in two standard sizes, thus enabling the processing of various tank sizes. The standard sizes are particularly designed for the processing of exchangeable vessels such as drums and IBCs.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Mobile stand with H-foot for tank volumes from 100 l. The mobility of the tripod is ensured by using castors and fixed castors. The tripod can be moved due to The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg can be realized (with ex-protection only realizable to a limited extend). Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The FRW is equipped with fixed and steerable wheels for mobility. The electric or pneumatic supply is guided through a laterally mounted energy chain. The mobile stand mixer FRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs. Various tank sizes upon request.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Rigid stand with H-foot for tanks that range in volume from 100 l. Under these conditions, the stand can be equipped with all fast running or gear-reduced mixers and their matching mixing elements. Mixer powers from 0.37 kW to 7.5 kW and support loads up to 100 kg – by means of a reinforced stand loads up to 300 kg – can be realized. The agitator is positioned on a telescope sleeve that is moved via the spring-suspended lid connected to the stand. The lift is done by a geared hand-wheel or electric with a lift drive and chain drive. The mixer is positioned on a cantilever beam which is fixed to a support slide that is moved on the stand column. The electric or pneumatic supply is guided through a laterally mounted energy chain. The floor stand mixer SRW is available in two standard sizes that are particularly designed for the processing of exchangeable vessels such as drums and IBCs. Various tank sizes upon request.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Electrical tote tank mixers for stainless steel IBCs The LRK-C series tote tank mixer and their drive units LRK-A are a special solution designed for operation on stainless steel containers with filling openings of at least 400 mm and mixing volumes from 400 l up to 1,500 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives. The mixing unit that remains in the container is connected to the drive unit with a bayonet coupling and a clutch. The drive is dismountable so that one drive unit can be used for several mixer units interchangeable. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The agitator shafts are borne in a bearing housing, which is welded into the container lid on the product side. The impellers are designed to fit through the filling opening DN 400 when being inserted.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives. All CR-M series mixers can be supplied as follows:

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CRP-E are equipped with a pneumatic drive. It has been especially designed for plastic IBCs with filling openings of at least 150 mm and volumes from 600 l up to 1,200 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator. Folding propellers that fit through the filling opening DN 150 mm are used for geared agitators. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly. Explosion-proof mixers are also feasible.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CR-E are designed for operation on plastic containers with filling openings of 150 mm and volumes from 600 l up to 1,200 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gears). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on a container traverse bridge, which is included in the scope of supply and clamped with a rapid fixing system to the cage frame of the IBC. The plastic bulk of the container is therefore not harmed by any static or dynamic loads by the agitator. The fixing of the traverse bridge is adjustable for various container models. The impellers are designed to fit through the filling opening 150 mm when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker.

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The FR series is a fast running electric drum mixer that can directly be mounted on 200 l steel drums with a 2“ bung hole. The mounting on the drum is done with a 2” threaded adapter with which the agitator is screwed into the bung hole. The agitator shaft is connected to the drive shaft by means of a sleeve coupling. Folding propellers are used as mixing elements, which can be inserted into the drum through the 2” bung hole when being folded. The FR series mobile mixer is delivered as a turn-key solution with an on-/off-switch with low voltage breaker and connection cable. Upon request, the FR series mixer can also be supplied with an integrated frequency inverter. Additionally we can provide you with a vessel clamp applicable for open lid drums.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

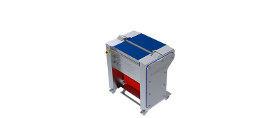

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Log Peeler CCP fully automatically and hygienically removes the casing from lunch meat and cheese products. The machine can be put together individually. A clear distinction between grey zones and hygiene zones allows the product casing to remain in the grey area, which increases the safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling. The flexible system permits simple and rapid conversion when changing calibers. Advantages Continuous production: buffering possible before and after the peeling process Casing remains in non-high risk area, increased safety for the peeled product Safe: constant control of the peeling process Optional hygiene kit Optional hygiene kit: UVC irradiation from underneath of conveyors in the product contact area UVC air disinfection within the peeling area

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five different executions: SmartPicker, single, double, triple or quad PickRobot. As powerful and highly efficient automation components with up to 230 picks per minute, the robots integrate perfectly into your line and ensure maximum performance. In combination with the Weber VMAX thermoforming technology, loading portions into an advancing index is possible, which maximizes performance even better than ever before. Advantages Flexible, reduced labor costs, and easy-to-clean Multi-variety and multi-layer packs available for compact spaces (overlapping, 90° rotation, variable portion shapes) Complete filling of the package when portions overlap Virtually eliminates human contact Improves food safety Handles all popular portion shapes and sizes

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

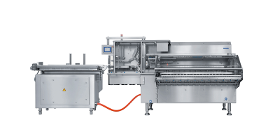

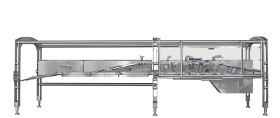

The infeeder CCA600/800 offers a high output with great flexibility. With a foil width of up to 830 mm, portions can be fed to up to six tracks of the packing machine in a wide variety of distribution variants. By adding various features such as diverse distribution variants, e.g. from four to six portions, or row completion, which supplements incomplete rows and inserts them again, infeeder CCA offers maximum flexibility and efficiency for many applications. Optionally, the infeeder can also complete rows and insert portions again. Advantages Automatic feeding of all commonly existing portion shapes and die formats Sets new hygiene standards Modular construction enables flexible design of the line length Optional: Automatic grouping of incomplete rows including automatic reintroducing UVC disinfection

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The compact SmartLoader is a fully automatic side loading system for single products or individual portions. Its features and capacity are optimized for sliced products. The SmartLoader can be combined with many slicers and portioners. Advantages Flexible Simple handling Hygienic Portions, groups, forms format sets, overlaps products Infeed operation – format sets, portions, individual slices or pieces

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

An idle cut blade head with automatic cutting gap adjustment ensures that the Weber Slicer 604 has a high yield with minimum giveaway. The product throat can be adjusted automatically in height and width, and the fully automatic central loading unit ensures rapid product changes. Products up to 1,700 mm in length are fed in automatically and processed at up to 600 slices per minute. The shear bar and side limit stop can be configured by motor and with programme control. That allows the Weber Slicer 604 to guarantee a precise cut and placement of perfect slices continuously. Options: Slice folder Variogripper Idle cut blade head Separate blade drive Interleaver Portion designer

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer 905 combines innovative slicing technology with versatility, efficiency and ease of operation. The extremely wide cutting throat and blade speeds of up to 2000 rpm allows the industry’s highest throughputs. The improved product control system provides perfect slicing results. Delicate and odd shaped products are easily loaded and sliced. The open frame design of the 905 allows easy access for operation, maintenance, and cleaning functions. The product control system has been upgraded to allow for more hygienic operation and quicker disassembly for cleaning. The Weber 905 has been designed and constructed to meet the world’s highest sanitation standards. The modular design allows the Weber 905 to be used in conjunction with all Weber up and down stream accessories such as stacking, party tray, automatic infeeding unit, etc.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. Industrial robots are the optimal solution for complex movements or systems with highest flexibility. We integrate and program the appropriate robot such as the Kuka robot and other brands.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We also create the programs ourselves to “breathe life” into machines and robots. After commissioning, we can run extensive performance tests. We strive for clearly structured program sequences. User interfaces should be as self-explanatory as possible and intuitive to operate. It is also important to have a well thought-out concept for user authorizations and parameter management.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

We install the necessary hoses between hydraulic power units and press cylinders. We also create piping and circuits for thermal oils and cooling water.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

This installation includes cable duct construction, cable laying, connection of the control cabinet, components and drives, and grounding in accordance with regulations.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

Many devices and machines are still moved by compressed air. The necessary hoses are professionally installed by us.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

The design of electrical systems and the creation of circuit diagrams are carried out on SEE Electrical, with all common output formats. Our electrical warehouse contains over 2,500 items. Annually we build more than 60 switch cabinets in all all sizes.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

The design of electrical systems and the creation of circuit diagrams are carried out on SEE Electrical, with all common output formats. Our electrical warehouse contains over 2,500 items. Annually we build more than 60 switch cabinets in all all sizes.

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

In our workshops, our experienced team assembles small subassemblies, devices, but also complete production systems. Bellingerstraße 3a: 1.000 m² assembly area (door height 4,5 m) with 10 t indoor crane

Request for a quote

ARTHUR WEISSBACH GMBH MASCHINENFABRIK

Germany

In our workshops, our experienced team assembles small subassemblies, devices, but also complete production systems. Bellingerstraße 14: 600m² assembly area (with 4 m passage)

Request for a quoteResults for

Equipment machine - Import exportNumber of results

52 ProductsCountries

Company type