- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industrial machines

Results for

Industrial machines - Import export

WEBER FOOD TECHNOLOGY GMBH

Germany

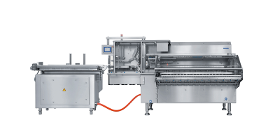

The compact SmartLoader is a fully automatic side loading system for single products or individual portions. Its features and capacity are optimized for sliced products. The SmartLoader can be combined with many slicers and portioners. Advantages Flexible Simple handling Hygienic Portions, groups, forms format sets, overlaps products Infeed operation – format sets, portions, individual slices or pieces

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Get the most out of your slicer blades! With the weSHARP 7000 sharpening center, you can quickly and easily get back the ideal slicing properties of your blades, even after intensive use in the slicer. The weSHARP 7000 is suitable for the refurbishment of all Weber Durablade Performance, involute and circular blades, and guarantees a precise and reproducible sharpening result with minimal material loss of the cutting edge. Thanks to program recognition and data storage, the sharpening process can be completed in the shortest possible time, and the use of tool-free fast-change systems also ensures that setup times are kept to a minimum. Advantages Simple operation with RFID technology Sharpening of all Durablade circular and involute blades Precise and reproducible sharpening result Precise sharpening process thanks to servo drive Convenient handling via touchscreen

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener SSG is suitable for gentle processing of all Durablade® involute blades with low material abrasion. The compact unit for various sharpening angles ensures constant sharpening of the cutting edge thanks to the rotating contour tracking. A counter is integrated for individual specification of sharpening cycles. A water bath improves the sharpening result. Advantages Gentle blade processing Low level of material removal Non-actively driven sharpening discs Compact device for different sharpening angles Constant sharpening of cutting edge thanks to all-round contour tracing Counter for the individual specification of sharpening cycles Water bath for improved sharpening Simple operation Very quiet running Long blade service life

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Sharpener KSG processes the blades gently with short setup times thanks to its intelligent sharpening technology. The sharpening unit is positioned via a visor. Sharpener KSG guarantees rapid, reproducible sharpening and has a long service life thanks to the sharpening disks which are not actively driven. A counter is integrated for individual specification of sharpening cycles. Advantages Long service life thanks to non-actively driven sharpening discs Sharpening unit positioning via sighting tool Gentle processing due to clever sharpening technology Quick, reproducible sharpening Counter for the individual specification of sharpening cycles Short set-up times Simple operation Clear, robust technology

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Every Weber slicer contains a Weber blade. The involute or circular blades are manufactured in Weber's own blade factory in Mecklenburg-Lower Pomerania and marketed worldwide under the Durablade brand. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, slicing quality, resilience and durability. Durablade blades are now also available to fit other manufacturers' slicers. Price advantage thanks to new manufacturing technology We are continuously investing in research, progress and manufacturing technology. We recently supplemented our blade production with a robot-controlled and high-performance production system, which combines quality assurance with maximum profitability. Weber Durablade involute and circular blades let you make the best cut at all times: with maximum hygiene, cut quality, resilience, durability and reduced prices.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products get transferred in a continuous-flow process. Products go through the scanner where the mass allocation of each product is determined using X-ray technology. The products are then weighed on the integrated weighing station according to their individual track. The system features a two-stage safety guarding for its radiation source. The CPS-X 400 is specifically designed for weight-accurate slicing of speciality products like Swiss Cheese and those which vary in density, e.g. fat to lean ratio. Optional: Detection of foreign objects: as well as ensuring reliable production, detecting foreign objects also protects units located downstream. This function can be used for detecting, e. g. stainless steel > Ø = 3 mm, glass/ceramic > Ø = 8 mm (product-dependent). Advantages Up to six products in one scan cycle Weight-precise cutting of cheese with holes Density determination of products with significant density differences (fat/lean proportion)

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The products to be recorded can be fed on multiple tracks into a LED camera system, which individually measures and then weighs them at a weighing station. Based on the captured data, the highest yield and minimal give-away is guaranteed during slicing of pieces/chunks and slices. Advantages Open design, simple handling High fault tolerance Excellent detection of products with extremely fluctuating color contrasts Precise measurement even in extraneous light The laser scanner is available in various sizes to fit your product.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Log Peeler CCP fully automatically and hygienically removes the casing from lunch meat and cheese products. The machine can be put together individually. A clear distinction between grey zones and hygiene zones allows the product casing to remain in the grey area, which increases the safety of the peeled product. With continuous production, the buffer can be inserted both upstream and downstream of peeling. The flexible system permits simple and rapid conversion when changing calibers. Advantages Continuous production: buffering possible before and after the peeling process Casing remains in non-high risk area, increased safety for the peeled product Safe: constant control of the peeling process Optional hygiene kit Optional hygiene kit: UVC irradiation from underneath of conveyors in the product contact area UVC air disinfection within the peeling area

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber PickRobot stands for the uncompromising automation of slicing applications. Specifically adapted to your application area, it can be used flexibly for all insertion tasks and is available in five different executions: SmartPicker, single, double, triple or quad PickRobot. As powerful and highly efficient automation components with up to 230 picks per minute, the robots integrate perfectly into your line and ensure maximum performance. In combination with the Weber VMAX thermoforming technology, loading portions into an advancing index is possible, which maximizes performance even better than ever before. Advantages Flexible, reduced labor costs, and easy-to-clean Multi-variety and multi-layer packs available for compact spaces (overlapping, 90° rotation, variable portion shapes) Complete filling of the package when portions overlap Virtually eliminates human contact Improves food safety Handles all popular portion shapes and sizes

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The CompactLoader is an especially compact infeeder which transports sliced portions fully automatically and feeds them into a packaging machine – all at a very modest footprint. Human touch of groceries is practically reduced to zero. Cleaning times of the CompactLoader are short and efficient. Advantages Compact, small footprint Modular adjustable system Weber hygienic design Arranges portions in die fomats, buffers them and places them in the packaging machine One design in different configurations – from base to top Space saving due to integrated rocker Optimal access to packaging machine by raising the buffer conveyors Infeeding belt foldable and swivable side-wise Easy cleaning, maintenance and service Options: Upper reject conveyor Buffer conveyor (2, 3, 4) Grouping conveyor (3, 4) Line divider – 2 axis 1 > n or 2 > 2 n Line divider – 3 axis 1 > n, 2 > 2 n, 2 > 3

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The infeeder CCA600/800 offers a high output with great flexibility. With a foil width of up to 830 mm, portions can be fed to up to six tracks of the packing machine in a wide variety of distribution variants. By adding various features such as diverse distribution variants, e.g. from four to six portions, or row completion, which supplements incomplete rows and inserts them again, infeeder CCA offers maximum flexibility and efficiency for many applications. Optionally, the infeeder can also complete rows and insert portions again. Advantages Automatic feeding of all commonly existing portion shapes and die formats Sets new hygiene standards Modular construction enables flexible design of the line length Optional: Automatic grouping of incomplete rows including automatic reintroducing UVC disinfection

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Powerful derinding machine for large and small pieces of cheese. In addition to an ideal cutting width, the Weber Cheese Skinner offers product-specific height adjustment of the blade, meaning that natural and plastic rinds can be optimally removed. Maximum product yield is guaranteed. Advantages Powerful and with a compact footprint A special cheese transport roller and perfectly adjusted blades for optimal processing results Ideal cutting width for powerful derinding of large and small pieces of cheese Bolted blade with blade protection in cleaning position Unique geared brake motor with quick stop Options: special voltages

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer 305 is the entry-level model for state-of-the-art slicing technology. Thanks to the intuitive Weber Power Control, Slicer 305 is easy to operate. The programmable touch screen assures rapid product changeovers, and the shear bar and side limit stop can be configured for the product width. Weber hygienic design ensures that the system is easy to clean. Option: Stack lowering device Interleaver, Interleaver Speed Plus Pivotable blade safety cover Further options available. We will happily provide you with more information.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

The wide product throat in Weber Slicer 405 guarantees a high output, and the shear bar and side limit stop can be configured individually for the product width. Product change is manual and rapid, even with short products. Manual and automatic loading are available as options, and end pieces are ejected automatically. Thanks to Weber Hygiene Design, Slicer 405 is simple to clean. Options: Automatic loading Idle cut blade head Separate blade drive Clearance height infinitely adjustable Interleaver, Interleaver Speed Plus Portion designer

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

An idle cut blade head with automatic cutting gap adjustment ensures that the Weber Slicer 604 has a high yield with minimum giveaway. The product throat can be adjusted automatically in height and width, and the fully automatic central loading unit ensures rapid product changes. Products up to 1,700 mm in length are fed in automatically and processed at up to 600 slices per minute. The shear bar and side limit stop can be configured by motor and with programme control. That allows the Weber Slicer 604 to guarantee a precise cut and placement of perfect slices continuously. Options: Slice folder Variogripper Idle cut blade head Separate blade drive Interleaver Portion designer

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Short loading times are a key feature of the Weber Slicer 702. It masters the special challenges when slicing short products with short cycle times and an endless product flow. The involute blade system reaches performances of up to 1,500 slices per minute in idle cut operation. Options: Loading arm feeder Trimmer End piece management

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Weber Slicer 804 is among the most efficient systems in its class. The involute blade system cuts products up to 1,700 mm in length at a maximum speed of 2,000 slices per minute. The automatic central operation ensures quick product changes. Slicer 804 uses a blade head with an idle cut function, which positions slice thicknesses between 0.1 millimetres and 50 millimetres precisely in various presentation forms. The 400 mm wide and 180 mm high product throat permits four 90 calibre products or three 100 x 100 products to be processed simultaneously. The system includes a programme-controlled, automatically configurable product clearance height and width. Weber Hygiene Design ensures that the system is easy to clean. Options: Slice folder Variogripper Idle cut blade head

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

WEBER FOOD TECHNOLOGY GMBH

Germany

The Weber Slicer weSLICE 9500 is the new high-performance machine in the slicer portfolio, which once again set the standard with regards to quality and performance. On the one hand, the uncompromising slicing quality and performance is achieved using the new Weber DirectDrive technology. The product is precisely guided by the direct drive of all components, so that in addition to perfectly sliced, visually appealing slices, the highest portion weight accuracy is achieved while at the same time providing maximum protection for the product. On the other hand, equipment highlights such as the Weber Durablade Performance involute blade ensures the best slicing quality. Moreover, the Vario technology of the new slicer-flagship weSLICE 9500 contributes to this unique performance. If Weber vacuum gripper technology is used, the product yield is increased even further, as remaining end pieces are reduced by more than half.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N (6-7 bar air pressure) • Cost effective from an annual quantity of around 500.000 blind rivets (related to the german market) • Up to 50 % time and costs savings compared to standard blind rivet devices • Rivet pistol has a large action radius • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Up to 40 blind rivets can be processed every minute • Electronic system controls • Maintenance display & simple fault diagnosis • Customer-specifi c software modifi cation is possible • Rivet mandrels are disposed of by vacuum system • Optional Spring loaded trigger system • Interface for external memory programmable control system (SPS) can be realised via GESIPA® interface

Request for a quote

UNIFLEX-HYDRAULIK GMBH

Germany

The new 2" 4SH + SAE R 15 hose cutting machine for workshops (also as a 3" industrial machine available). Designed to perfection. Unique drive motor with double bearings and oversized shafts •Reduce scrap with straight cuts •More cuts between sharpening while increasing profits •Less contamination in the shop and in the end product will result in more parts out the door and a better environment in the building •Maximizes motor life, giving you the lowest cost of ownership in the market •Cut faster and generate a more saleable product Quality steel blade •Long lasting German quality steel blades, lowering the cost of ownership Compact design •Ideal for a mobile service CE compliant •Brake motor for safety •Security shield

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

to reduce the mass of the spiked roller, for example, in and out pivoting perforation roller for partial perforation

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

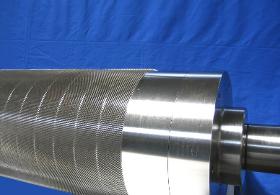

A ready-to-install needle roller on its own shaft or segments to place on the roller for different applications - more details on our homepage! The construction of complete needle or perforation rollers depends on the intended use. Please describe your requirements exactly! Perforation rollers usually consist of individual segments, which are mounted on a shaft or a tube. The mass inertia can be reduced by bearings between the shaft and the tube. In case of driven shafts, the segments can be firmly anchored to this. A sketch of the installation situation with a short description of the requirements helps us to find the optimal solution!

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Our modular system provides cost-effective, simple and flexible integration of a perforation in your system. Working widths up to approx. 4 meters can be realized, optionally with manual or pneumatic delivery of the perforation roller. This gives you an exact setting of the perforation depth. A quick shift of one to another machine is also possible!

Request for a quote

TAMBULA GMBH - PRECISION IN PERFORATION

Germany

Integratable in the production line, only the inspection windows of the bags will be perforated. The neighbor areas of the inspection windows are left unperforated. The perforation holes are melted down with hot needle rollers of steel at high temperatures.

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec offers complete production systems for manufacturing long-fiber reinforced thermoplastics (LFT) in pellet form and as UD tapes (unidirectionally reinforced tapes) as well as impregnated fiber strands and profiles. The system works extremely flexibly and is designed for variable formulations and high throughputs at a production speed of 50 m/min. We deliver an LFT system design customized to meet the respective customer requirements, all from an single source – from material development, to testing and commissioning on location at the customer‘s premises.

Request for a quote

KLN ULTRASCHALL AG

Germany

“Powersonic” is a type of KLN transducer systems with a particularly good cleaning effect and especially solid design. Thus we give full guarantee for up to 12.000 hours in max. 3 years. Submersible transducers are ultrasonic transducer systems in hermetically welded metal housing, inside of which piezoceramic transducer elements are incorporated. They are arranged at the bottom or at the sides of cleaning tanks. The HF current supply is realized via a power supply line which is lead via connection box at the back, a pipe elbow or a flexible metal mesh hose. Various sizes of submersible transducers make possible to use them in operating frequencies differing from 20, 25, 30, 40 up to 132 kHz.

Request for a quote

KLN ULTRASCHALL AG

Germany

Solvent cleaning machines / non-flammable solvent Compact • Standard with Automation • Freely programmable • Ultrasound and Agitation • Vapor Rinse • Freebord drying • Non-flammable Solvents • Meets YOUR BUDGET with Premium Features

Request for a quote

KLN ULTRASCHALL AG

Germany

The machine of series KT can be applied universally. It is designed for the industrial part cleaning. Application fields: metal degreasing, electrical industry, optical industry, medical technology, maintenance and service etc. The compact design of the machine as 3-tank system guarantees a high cleaning quality together with space-saving location. The basic version consists of a heated ultrasonic tank (tank 1) and heated cascade rinsing (tank 2 and 3). Additionally a separate dryer corresponding to the size of the compact unit can be made available. The tanks are incorporated in a solid frame. Optionally a stainless steel base frame can be delivered. Armatures, tank and frame are made of stainless steel. All valves can be easily operated at front of the machine. All electrical operating elements are on the front of the machine. They are each assigned to the tanks.

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN has developed spray unit concepts, e. g. for precision cleaning of electronic components, here focusing on cleaning of DCB, ceramics and polymer-FR4-SMD in inline continuous spray units. KLN plans and manufactures cleaning plants using state-of-the-art technologies. The machine concept is adapted to the referring chemical products used, thus safe monitoring and process control is guaranteed. The machines are made completely of stainless steel to achieve a high chemical resistance. Moreover, the machines can be used in a versatile way, they have an extremely sturdy and long-life design

Request for a quoteResults for

Industrial machines - Import exportNumber of results

73 ProductsCountries

Company type