- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- heat exchangers

Results for

Heat exchangers - Import export

BUSS-SMS-CANZLER GMBH

Germany

The falling film principle requires an even distribution of the feed liquid. To achieve this distrubution one or more distribution trays are located in the top head of the evaporator over the complete tube sheet. Our proven distribution system makes sure that the inner surface of each individual tube is properly wetted. The liquid film moves down the tubes by gravity force. Heat applied through the tube wall effects boiling-off the light fraction from the film. The picture shows a co-current operating evaporator with vapour and liquid leaving the bottom of the evaporator into the separator vessel.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

Short path distillation is a thermal separation technology operating at process pressures in the range of 1 to 0,001 mbar. It lowers the boiling temperature and is an excellent method for gentle thermal treatment of heat sensitive, high boiling products. The short path evaporator consist basically of a cylindrical body with a heating jacket, a rotor and an internal condenser. The rotor creates a mechanically agitated, thin product film on the heating surface inside of the body. By means of gravity the product flows down in a spiral path, whereby the volatile portion of the product evaporates. The vapour passes by the shortest route and with practically no pressure drop to the internal condenser. The non-volatile portion reaches the lower part of the evaporator and is discharged through the bottom product outlet. The residual vapours and inert gases flow through the vacuum nozzle to the vacuum system.

Request for a quote

AVITEQ VIBRATIONSTECHNIK GMBH

Germany

AViTEQ-vibrating heat exchanger are used in a number of processes in which bulk solids have to be cooled, heated, dried etc. These special-purpose units are able to perform the heat exchange process during transportation. Usually, this occurs indirectly through the use of double bottoms to accommodate the heat exchange medium (oil, water, air, etc.). AViTEQ heat exchangers are employed in practically every industry (chemical, food, plastics, pharmaceutical, recycling and raw materials). The spiral conveyor, which offers large heat exchange surfaces from a small footprint through its coils, is an especially cost-effective solution. A laser-welded version, which offers maximum density in return for minimum heat admission during manufacturing operations (no welding stresses to cause delays), is playing an increasingly important role for these special units. Advantages & benefits gentle product treatment optimised and customised modification to suit existing processes low wear and pra

Request for a quote

THIELMANN ENERGIETECHNIK GMBH

Germany

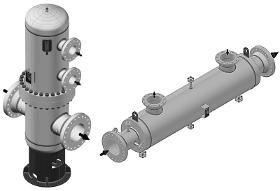

TUBE BUNDLE HEAT EXCHANGER, TYPE VEV/VEV-L/VEV-ex Gas / Water; horizontal / vertical CHARACTERISTICS Optimal load case design Flow stream optimized design Vibration-optimized design OPTIONS Customer-specific design for various design codes (ASME, EN 13445, SVTI, AS1210, PD5500 etc.) Design according to TEMA Customer-specific approvals Customer-specific testings Application for sour gas (NACE) Design for low temperature down to -50 ° C Design pressure up to 300 bar Customer-specific nozzle arrangement GENERAL Heat exchangers (heat exchangers) heat gas for a subsequent system requirement or to counteract the Joule-Thomson effect. For example, For example by pressure reduction in a gas-pressure control. Heat exchangers can also be determined in the reverse mode of operation as coolers. The design is carried out as a steel welded construction in vertical or horizontal design.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Heat exchangers - Import exportNumber of results

4 ProductsCountries

Company type

Category