- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- feed rollers

Results for

Feed rollers - Import export

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Great feeding accuracy of +/ 0,1 mm Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Synchronized drive of all bottom work rollers and both feed rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic full piloting Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

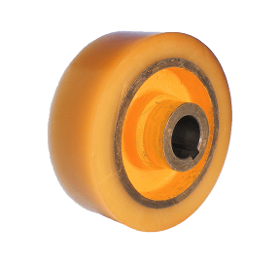

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Wood-Her rollers consist of an aluminum core. Light-colored rubber is used for the coating, in addition to the polyurethane materials that have long been tried and tested in the woodworking industry, and mainly the elastomer Vulkollan®. The core mounting holes have two side holes.As a service, we offer our customers the opportunity to have their used pressure and feed rollers re-upholstered by us. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Harbs rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. We would be pleased to advise you on which harbs rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design in smooth or grooved form and the most suitable degree of hardness must be determined by the customer. Weinig rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core mounting holes are designed as a keyway or with three side holes.The Weinig rollers are mainly coated with the elastomer Vulkollan® patented by Bayer. We would be happy to advise you by telephone or at your location regarding high-quality and cost-effective design of pressure and feed rollers.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

We manufacture pressure and feed rollers for moulders, feeders and belt sanders according to drawings or samples, completely ready for installation. The choice of roll coating, the design of the roll coating in smooth or grooved form and the most suitable degree of hardness for the roll coating must be determined customer-specifically. Our employees will be happy to advise you by telephone or on site regarding high-quality and cost-effective design of pressure and feed rollers.Gubisch rollers consist of a core made of aluminum or gray cast iron. In addition to the polyurethane materials that have long been tried and tested in the wood processing industry, the elastomer Vulkollan® is mainly used for the coating. The core receiving hole is designed with a feather keyway. We would be pleased to advise you on which gubisch rolls can be used in your processing, in order to achieve top process results. Please note, other trim types are available upon request!

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

The MMC 600/900 is the basis for a series of machines that, via several accessories and options, can be fully customized to individual needs. In the basic version the machine consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. Several accessories like a Y-axis, an A-axis and/or C-axis are available, thus expanding the range of machinable parts to microstructures, lenticular structures, spheres, polygons and so on. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement and even machine interferometers for insitu measurement of workpiece shape, make the MMC 600 and 900 machines an effective tool. Besides further accessories, there is the possibility to make customized solutions, to adapt the machine to your needs.

Request for a quote

ECKARDT SYSTEMS GMBH

Germany

Dosing systems DOS: Perfectly controlled oil feed rates Thanks to automated control of the oil feed rate DOS series dosing systems offer the highest levels of efficiency and flexibility in your lubrication processes – and it does not matter if continuous lubrication is desired or just a single drop is required. The machine cycle time determines the interval at which the lubrication valves open. The following DOS dosing systems are available from us: DOS 10 MR, DOS 10 MR H: system for pneumatically operated roller lubricators WF 60 WG, WF 110 WG, WF 110 MOT. Optionally available with poppet valve DOS 40: reservoir and control unit are separate. Also available for squeeze-on lubricators, but without pressure vessel (replacement: VB 10). DOS S: version for sector lubrication; in this case the oil feed for each roller can be programmed separately (via PLC). Other configurations include, amongst others, an extension to facilitate oil supply directly from an oil drum or an option to operate

Request for a quote

GSW SCHWABE AG

Germany

Both straightening and (servo) feeding performed in one operation Saves floor space as 2nd loop between standalone straightener and servo feed is eliminated Large entry pinch rollers driven synchronously with all bottom work rollers Great feeding accuracy of +/ 0,1 mm Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Operator interface provides simple insertion or recall of feeding paramenters or memorized programs Hard chromed rollers Polyurethane coated rollers Hydraulic cleaning stroke Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Motorized central height adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

In the basic version the MMC 5000 consists of a main X-axis featuring a linear air bearing (feed axis), a linear roller bearing Z-axis (infeed axis) and the milling spindle (air bearing) mounted on top of the Z-axis. The main application is face milling of optical and mechanical precision components. A Y-axis is available as an option. Another useful accessory is a second milling spindle, used perpendicular to the first one, thus allowing for the machining of two sides of a workpiece to perpendicularity in one setup. Accessories, like vacuum chucks, different milling spindles, touch probes for part thickness measurement, machine interferometers and other sensors for insitu measurement of workpiece shape and roughness, make the MMC 5000 machines an effective tool. In addition, various sensors are available for measuring of the workpiece geometry and surface quality during the manufacturing process.

Request for a quote

MANTIS ULV SPRÜHGERÄTE GMBH

Germany

Which purpuse are MAFEX-Silage sprayers used for? Mafex-Silage spraying systems ares used for application of liquid silage support agents directly during chaffing. How and where should a MAFEX-Silage sprayer be assembled? Atomisers are installed in protective tubing at an appropriate location with an adapter suited to the chopper. The atomiser cannot clog thanks to its special design and installation angle. On John Deere choppers installation by the accelerator, for example, takes place so that plant parts are evenly covered by the droplets as they are discharged. On the other hand and depending on the year ofmanufacture, atomisers on New Holland choppers are installed near the feed rollers or, likewise, by the accelerator. As a rule, installation is possible on any chopper (e.g. Claas, Krone, etc.). Stationary installations on conveyor systems, for example, are also possible. Advantages Optimisation of the silage process Minimum application volumes Optimal distribution of active ag

Request for a quote

SERVOLIFT GMBH

Germany

SERVOLIFT’s drum blender is designed for the demands of the pharmaceutical and chemical industries. Equipped with easy-to-use equipment, optimal ergonomics, converted to a space-saving and compact machine housing. The blender offers the ability to take up drums of varying sizes. The drum blender can be ideally connected to previous or follow-on processes, to refill or sieve into underneath placed containers, for easy attachment of drums either manually or hydraulically, to blend various containers with fitting clamp or take-up systems. Blending and Handling Technical description Stainless steel or cGMP-compliant design Can lift all customary drums as well as special drums Free-standing or floor- or ceiling-mounted design Loading using trolleys, hand lifters up to fully automatic roller conveyor feeds and unloading Various container clamping systems, from manual up to fully automatic designs Safety housing depending on where set up, and processes Standard tipping setting on the...

Request for a quote

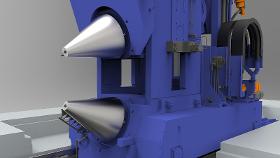

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quote

MFC DEUTSCHLAND GMBH & CO KG

Germany

The cleaning card was developed for ATMs and bank statement printers. The microfiber surface cleans the magnetic head and chip contacts. The feed rollers are embedded and cleaned by the special length of the microfibre.

Request for a quote

MFC DEUTSCHLAND GMBH & CO KG

Germany

Cleaning cards for the Bill to Bill & MFL by Suzo Happ + CashCode, microfiber surface, moist in the bag. Optical sensors, feed rollers and the shaft of the device clean especially the height, width and the arrangement of the raised areas in the microfiber surface.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Drum chippers prepare long and short round wood, slabs, saw mill waste, veneer waste, board trimmings, and various waste wood into high quality wood chips. Annual plants such as cotton stalks or bamboo can also be processed. The drum chipper size and design can be tailored according to the wood type or infeed material to be prepared and the desired wood chip quality. The most suitable sized chipper is determined by the maximum infeed diameter to be processed and the desired throughput capacity. The required chip length will also influence the performance rate of the chipper. Characteristics, Function Large feed rollers assure a process reliable infeed at a constant speed Pivoted feed system for automatic adjustment of the infeed height Hydraulic swing drive system for constant pressure and shock absorption Robust, electrodynamically balanced chipper rotor Large flywheel effect to compensate for sudden peak loads Amply dimensioned V-belt drive Start process supported by...

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Compaction Custom-made solutions With our variety of granulating systems we produce granulates or compacts in every shape and size for our customers in contract work. Our modern granulating systems consist of roller compacters, pelletizing systems, drum granulators and extruders. Supplementing these are our granulating systems for vacuum packing, in addition equipped with a fully automatic compression force regulation. Through high-tech to the perfect product Our compactor plants made from stainless steel usually consist of the product feed to the roller, a vent unit by vacuuming as well as counter-rotating rollers with continuously adjustable compression force and speed regulation. Here a pre-granulation of pressed slugs, then the fine granulation of pre-granulated goods and the screening of the fine particles under continuous feedback of the screened fine grain are carried out. Our process engineers have multiple ways to customize both the shape and the properties of the final pr

Request for a quote

GERMANBELT SYSTEMS GMBH

Germany

germanShock® impact bars germanShock® IP impact bars replace conventional buffer rollers at in-feed and absorb the impact energy of dropping bulk material, thus reducing damage to the belt. Combination with our germanLine® skirting rubber provides effective side sealing at in-feed. ... more

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quote

CASTSERVICE GMBH

Germany

The grinding and the combustion of natural resources such as wood and coal for energy production causes abrasive and thermal wear and decreases the service time of its wearing parts. For problems we offer you a consistent solution: we develop and supply ready to install wear-cast-parts made out of heat resisting gray cast iron, highly heat resisting stainless steel casting and wear resisting heat treatable steel. The use of CS-specific-materials results in a higher service life. Our grate bars can be found in roller grates, feed grates, traveling grates or horizontal grates. The development and manufacturing of water-cooled grate bars is also part of our product line. Our services include the preinstallation of single grate lines in order to check the dimensional stability and quality. We can also offer customer specific solutions for the entry area and the outrun area of rotary kilns in the field of grinding tools and crushing tools.

Request for a quoteResults for

Feed rollers - Import exportNumber of results

28 ProductsCountries