- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- electric motor shafts

Results for

Electric motor shafts - Import export

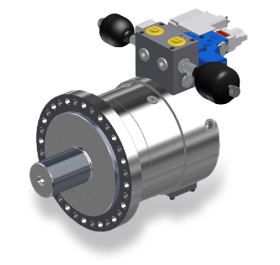

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The output shaft of the HSH swivel motors has radial and axial hydrostatic bearings. Here, radially and axially arranged bearing pockets are supplied with pressurized oil via a separate pressure connection. As a result, the output shaft is centered radially and axially between liquid cushions and all metallic contact surfaces are permanently separated from each other by a thin liquid film. This eliminates wear caused by metallic friction in any operating state, even at zero speed compared to hydrodynamic plain bearings. In conjunction with highly dynamic control valves and angle of rotation sensors, these actuators are preferably used in controlled systems in which disturbance variables such as friction and the stick-slip effect must be reduced to a minimum. Furthermore, due to the lack of internal seals, they are ideal for test series with large numbers of load cycles where an interruption, e.g. due to the replacement of internal seals, is not permitted.

Request for a quote

GEMÜ GEBRÜDER MÜLLER APPARATEBAU GMBH & CO. KG

Germany

The GEMÜ 539 2/2-way globe valve has a hollow shaft actuator and is electrically operated. The eSyDrive hollow shaft actuator can be operated as an OPEN/CLOSE actuator or as an actuator with integrated positioner or process controller. The valve spindle is sealed by a self-adjusting gland packing providing low maintenance and reliable valve spindle sealing even after a long service life. A wiper ring fitted in front of the gland packing protects the seal against contamination and damage. An integral optical and electrical position indicator is standard. — Linear or modified equal-percentage control characteristics — High flow rates — Force and speed are variably adjustable — Extensive diagnostic facilities — Operable via web interface eSy-Web — Integral optical position indicator and LED high visibility display — Standard gland packing suitable for vacuum up to 20 mbar (abs.)

Request for a quote

FRANZ EISELE & SÖHNE GMBH & CO KG

Germany

Eisele rotary lobe pumps have been constructed since 1983 and have proved themselves in the agricultural and industrial sectors. Detailed key data here: Rotary lube pump (rotary piston pump) for pumping media up to approx. 30% TS Rotary lobe with metal core and perbunan coating Drive with PTO shaft or electric motor (7.5 / 11.0 / 15.0 / 18.5 / 22.0 kW) Pumping capacity from min. 450 l/min. to 6,000 l/min (depending on the media) Pressure performance 4 - 10 bar The rotary lobes can be changed quicker and easier by opening the four ring nuts of the cover, easy as one-man operation. Vacuum and pressure side can be freely selected by re-plugging the drive shaft Standard with front side-wear plates in the pump housing and cover Mobile pump stations with one or two rotary lube pumps (pumping capacity up to 7,400 l/min.) Eisele rotary lube pumps have proved themselves in the agricultural and industrial sectors. A continuous further development guarantees a high technical standard....

Request for a quote

IGUS® GMBH

Germany

For designs that require a stepper motor with directly integrated lead screw, drylin® E offers the ideal solution. The stand-alone versions with NEMA11 stepper motor (very small type) are available in a compact type with or without encoder. The lead screw is centred and in combination with the dryspin® high helix thread technology, the system has a long service life. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

IGUS® GMBH

Germany

The new direct-current motors with worm gear enable quiet and economically efficient operation with drylin® lead screw units. The worm wheel has a spline to which the drive pin of the linear unit is connected. As a result, a motor flange and coupling are unnecessary and, this taken in conjunction with the motor adapter angled by 90°, the structure of the linear module is very compact. Thanks to the integrated magnetic rotary encoder (2-channel hall), the new DC motors are suitable for positioning. - Space-saving and compact design - Easy to fit - Quiet operation - Rotary position encoder included - Suitable for: SLW-BB, SAW, ZLW

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

IGUS® GMBH

Germany

Versatile choice due to the high torque and speed. This motor is the best choice for most applications with medium loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. The connector interface provides a high IP65 protection level (IP: International Protection). The higher the IP rating, the better the motor is protected from the ingress of dirt and water. The encoder sends signals from the motor to the motor control. The encoder verifies that the required linear motion has occurred precisely as required. Encoder = increased machine accuracy.

Request for a quote

IGUS® GMBH

Germany

This little motor has impressive torque and high RPMs. Reliable operation with quick movements of low loads. Stepper motors from igus® are a good supplement to drylin® linear axes. They are characterised by their cost-effectiveness, their precision and easy control. They work reliably under the most varied environmental conditions (depending on the selected class of protection IP). The igus® stepper motors can be connected to the most common motor controls using standardised electrical connection. Motors with stranded wires are the least expensive and the most common stepper motors. The connecting wires for this type exit from the housing and will be connected with a JST connector. They are usually installed in machines and equipment that have an additional housing or are used in clean environments.

Request for a quote

IGUS® GMBH

Germany

Find the suitable motor for your application: simply enter your requirements and receive suitable suggestions.

Request for a quote

FÖHRENBACH GMBH

Germany

2-phase stepper motors Our 2-phase stepper motors are reliable and low-cost drives with a long service life. They are available in different sizes and types of power output, are continuously developed and are thus suitable for a variety of applications. AC servo motors The AC servo motors meet the highest demands regarding dynamics and accuracy and are used if dynamic, exact positioning or smooth running characteristics are required. The different types of power output and sizes cover the most diverse requirements. The benefits at a glance Highly dynamic High efficiency Long service life

Request for a quote

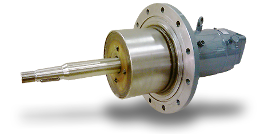

KAISER-MOTOREN GMBH

Germany

Watercooled electric motors can be realised in any possible mechanical and electrical customised version. They can be realised in vacuum tight version for fan drive on thermal treating oven.

Request for a quote

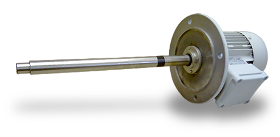

KAISER-MOTOREN GMBH

Germany

Electric motors are available in nearly any mechanical and electrical customised version

Request for a quoteResults for

Electric motor shafts - Import exportNumber of results

12 ProductsCountries