- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- edge board

Results for

Edge board - Import export

PRÜFREX INNOVATIVE POWER PRODUCTS GMBH

Germany

What do we take care of from the very beginning? Among other things, making sure the outside edges of circuit boards benefit production, thinking about how a housing can be perfectly planned in, working out where connectors will be a nuisance or where wide mechanical tolerances can be permitted. For decades, we have developed and produced together under one roof. Engineering in a way that benefits manufacture is part of our company DNA.

Request for a quote

KNÜPPEL VERPACKUNG GMBH & CO. KG

Germany

Edge protectors made of solid cardboard prevent the load from slipping, absorb shocks and prevent the strapping from cutting in.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

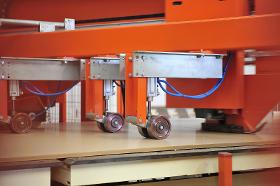

The boards are cut o the endless mat in the saw section. The process becomes a discontinuous one that is characterised by cycle times from this point on. The saw section includes the board edge-trimming and saw units. The board is cut by saws that are positioned at right angles to the endless board and that cut straight proportionally to the feed of the press. It is possible to change the tools without interruption to the production process depending on the number of individual units. longitudinal edge trimming device 2 edge-trimming units – no production possible while tools are being changed 2 edge-trimming units with the option for retrotting additional units 4 edge-trimming units for interruption-free changing of the saw blades Bevelling of the endless board after trimming Multi-diagonalsaw Up to two saw beams each with two units, i.e. four saws maximum Number of saws depending on the feed and desired board length

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The boards are trimmed, cleaned, checked and (if necessary) cooled in the nishing line. Features, function Any excess material caused by the decorative paper being larger than the carrier board is removed from edges on the nished boards in the edgetrimming unit. Rotating brushes then remove any residues that are clinging to the surface. A member of sta will visually assess the quality of the coated board on both sides at the inspection station. The boa station so that it can be inspected from the bottom. The board is then placed in the stack appropriate for its quality Advantages The modular design allows basic modules and optional modules to

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Siempelkamp's continuous saws are a tried-and-tested solution for plants with highest outputs. The saw throughput does not depend on the number of cuts and is therefore superior to other cutting solutions, particularly for large master boards. Continuous saws also permit in-line quality grading. This means that the combined sanding and saw line is able to deliver sorted stacks of nished boards from the master boards in a single stage of work. This allows investment and operating costs to be minimised. The cut-to-size saws may be combined in-line with a sanding machine or set up separately just as a cutting system Features and functions Continuous saws for longitudinal and horizontal cuts Scoring unit and main saw blade for top-quality edges Reliable guiding of the board using chains and/or rollers to ensure accurate cutting Trimming of the edges directly by the tool, no additional conveyors and follow-up work required

Request for a quote_0f73db15_o.jpg)

RIGA WOOD GMBH

Germany

Riga Composite Birch plywood ( Riga Ply) overlaid on one or both faces with a special material or such a material is used as a core to improve mechanical properties or visual appearance of plywood. Further mechanical processing, board and edge sanding and lacquering is available, also manufacturing of furniture elements. Riga Composite PPL PPL is 0,2 mm grey (RAL 7045), white (RAL 9016) or black (RAL 9017) slightly textured polypropylene overlay. PPL overlay is flexible, does not crack, resistant to UV and chemicals. Riga Composite PPL is applied in horse trailer walls, lining of trailer walls and ceiling, shop and warehouse fitting. Riga Composite TPO TPO is grey (RAL 7000), thermoplastic, textured polyolefin overlay. It is flexible, wear resistant, does not crack, resistant to chemicals and UV. Riga Composite TPO is applied in van and tent shed floors. Sizes 1250 mm x 2500 / 3050 mm 1525 mm x 2500 / 3050 mm Other colours, overlays and core materials on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Edge board - Import exportNumber of results

6 ProductsCountries

Company type