- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- direct acting

Results for

Direct acting - Import export

KENDRION KUHNKE AUTOMATION GMBH

Germany

Direct acting valve, 15 mm width, two individual electrical connection possibilities.

Request for a quote

INFICON GMBH

Germany

The INFICON Gemini Inverted Magnetron Vacuum Gauge is the workhorse for all vacuum measurement applications (pending). Gemini combines two sensor systems into one small device to measure from atmosphere to 1x10 – 9 mbar. The patented ultra-low magnetic stray field design opens up a whole new range of applications. A unique interchangeable dual chamber sensor unit avoids cleaning cycles and reduces maintenance, making Gemini the most robust and economical vacuum gauge of its kind. Gemini Cold Cathode and combination comes with fully integrated digital electronics, providing ultimate flexibility for system integration. Cold cathode and Pirani combination option provides seamless transition, reliability, practicality and flexibility across wide ranging applications. MPG500 series represents the latest Technology to act as direct replacement for Cold Cathode or Penning Transmitters of the PTR 90 / PTR 225 (analog Versions) series. Part-No Typ Part-No Typ 3MB0-006-000P MPG500 SS,...

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force to be measured must be introduced axially and perpendicularly to the entire surface of the inner and outer bands of the sensor in the opposite direction. Conversion of the acting force into an electrical output signal is performed by strain gages connected together in a full bridge circuit. To achieve optimal accuracy, the base of the sensor should rest on a smooth level surface, hardened to at least ≥ 58 HRC with sufficient dimensions. The base cover welded to the surface has a stabilizing effect on the sensor element. Lateral forces must be avoided anyway as they distort the measured results. Tension and bending relief for the sensor cable is to be carried out on the machine side. FEATURES: — Measuring ranges from 0 ... 100 N to 0 ... 200 kN — Centric throughout hole — Flat disc design — Made of stainless steel — Completely welded sensor body — Nominal characteristic value standardization possible — burster TEDS optionally available

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The ContiRoll® press is the core element of the forming and press line and at the same time the focus of Siempelkamp’s innovations. More than 300 presses have been sold to all parts of the world since its launch 30 years ago. The concept has been continuously developed by Siempelkamp ever since, especially product quality, user friendliness and resource eciency. The exible infeed section adjusts to the formed mat in dependence on the recipe thus oering an optimal combination of a quick pressure build-up and a reliable evacuation of air from the mat. The booster heater integrated in the infeed end transfers a maximum of thermal energy into the mat. Very fast pressure and temperature build-up ensure an optimal density prole and excellent physical properties of the engineered board. Today, the 8th ContiRoll® generation is in use. It oers almost isobaric pressure distribution. Patented pressure distribution plates ensure consistent pressure in working direction acting on the product.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

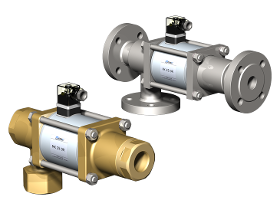

MÜLLER CO-AX GMBH

Germany

The lateral valves are solenoid valves with two or three connections and two switch positions in the basic position closed (NC). In this type of construction, the magnetic drive is not arranged coaxially, but laterally. Additionally, this valve construction is not pressurebalanced, and the switchable pressure range is therefore significantly smaller than with valves in a coaxial design. However, the lateral design is often sufficient for applications in the lowpressure and rough vacuum range and, thanks to its simple construction, also offers a very attractive price. Lateral valves are particularly wellsuited to the packaging, glass, metal, and furniture industries as a robust and fast switching valve for lifting tools (suction cups). Since they do not require dynamic seals, they are ideally suited for rough use in a dusty environment. They are therefore also recommended for use in vacuum furnaces.

Request for a quote

MÜLLER CO-AX GMBH

Germany

The lateral highpressure valves are valves with two or three connections and two switching positions. The pressure range extends from vacuum up to 500 bar. In this type of construction, the valve drive is not arranged coaxially, but laterally.

Request for a quote

MÜLLER CO-AX GMBH

Germany

Whenever several valves are to be used in a confined space and with minimal piping, a module or strip solution is recommended. In contrast to single piping, the expense for valve piping, fittings, working time, and possible leaks is almost cut in half.

Request for a quote

MÜLLER CO-AX GMBH

Germany

The 3/2way solenoid valves are electrically operated solenoid valves with three connections and two switching positions. These valves are hermetically sealed on the outside and have proven themselves when used with liquid, gaseous, dirty, or poisonous (toxic) media. Even if the seals are completely worn out, no process medium can escape.

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

Safety Relief Valves / Blow-Off Valves WITT safety relief valves (blow-off valves) protect against overpressure by venting excess gases from pipelines, gas receivers and other equipment. The spring-loaded, direct-acting safety relief valves (blow-off valves) are suitable for individual opening pressures from 5 mbar to 45 bar (approx. 0.07 to 1 435 psi). The compact size allows easy installation in any orientation. A dust cap protects the safety relief valves (blow-off valves) against dirt. WITT safety relief valves (blow-off valves) are available in brass or stainless steel, as a ventable version, and with or without condensation outlet.

Request for a quoteResults for

Direct acting - Import exportNumber of results

11 ProductsCountries

Company type