- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- current sensors

Results for

Current sensors - Import export

SCHNIEWINDT GMBH & CO. KG

Germany

CSN® Current Sensors are used for current measurement in control and protection systems in power transmission links (AC and DC applications). The CSN® type Current Sensors are based on highaccuracy resistive sensors (shunt) respectively iron free cores (CSN® AirCoil). There are selfsupporting structures available where the CSN® Current Sensor is mounted on top of a composite insulator, as well as variants in which the CSN® Current Sensor will be mounted hanging in the busbar. Schniewindt has implemented CSN® Current Sensors for nominal currents of up to 5 kADC at system voltages of 800 kVDC, which have been successfully typetested. Also for the precise measurement of small currents (1 to 10 A), such as transient currents in capacitor banks, Schniewindt offers appropriate solutions. All of our CSN® Current Sensors are individually designed according to customer requirements.

Request for a quote

EPP ENERGY PEAK POWER GMBH

Germany

3 x Modbus current sensor 100 A for SolarEdge Modbus energy meters

Request for a quoteEPP ENERGY PEAK POWER GMBH

Germany

The highlights at a glance Manufacturer: SolarEdge Manufacturer type: SECT-SPL-1000A-A Manufacturer item number: SECT-SPL-1000A-A Item no.: MO-6751

Request for a quote

EDDYLAB GMBH

Germany

eddyMOTION is a Windows-based analysis and configuration tool for eddy current probes. In combination with the TX electronics from eddylab GmbH, the software tool combines several performance features: The functional areas oscilloscope, FFT analysis, data logger and waterfall diagram, enables the visualization and documentation of mechanical movements. eddyMOTION also suites the on-site linearization of eddy current sensors in a traceable manner, without external assistance. In addition to the TX electronics and an eddylab eddy current sensor, a reference probe is required for this purpose: Together with the eddy current sensor, this probe measures the distance to the same material, with the reference probe serving to check the sensor.

Request for a quote

EDDYLAB GMBH

Germany

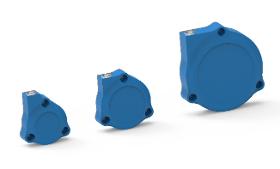

With an extended measuring range up to 45mm, the new eddy current sensor series completes the product portfolio of eddylab GmbH and at the same time combines all advantages of a non-contact eddy current measuring principle: With wear-free distance and displacement measurement, eddy current sensors are characterized by highest precision and dynamics. The new T14/T20/T40 series can withstand extreme temperatures in a range of -40...+150 °C without any problems and is insensitive to external influences such as dirt and dust. The new sensors with measuring ranges between 14 mm and 45 mm are also extremely compact and robust. This makes them ideal for use in difficult industrial environments or vibration measurements with larger amplitudes. Together with the TX electronics from eddylab GmbH and the eddy current software eddyMOTION, measurement data can be analyzed, visualized, and documented.

Request for a quote

EDDYLAB GMBH

Germany

■ Measuring on turbo vanes and shafts ■ TTL output for speed measurement ■ Analogue monitor output for gap control ■ High resolution ■ High dynamics ■ Low current consumption ■ High noise immunity

Request for a quote

EDDYLAB GMBH

Germany

The eddy current sensor series IC with integrated electronics guarantees highly accurate measurements thanks to linearized characteristic curve. Accuracy has been improved by up to a factor of 20 compared to previous models. The teach-in function allows the measuring range of the eddy current sensor to be optimally adapted to the respective application. Installation tolerances or material properties of the measured object can be compensated directly. Setting individual measuring range limits offers the user the greatest possible flexibility and simplifies sensor integration. As the complete analysis electronics are built into the sensor, installation and mounting are also extremely uncomplicated.

Request for a quote

EDDYLAB GMBH

Germany

High-quality eddy current probes: Beside robustness, high dynamics and high resolution the TX-Series also stands out with a wide temperature range from -60 °C up to 180 °C. ■ High precision measurement ■ High resolution (submicrometer) ■ High dynamics (124 kSa/s) ■ Minimal temperature coefficient ■ High noise immunity ■ Custom-made probes

Request for a quote

EDDYLAB GMBH

Germany

The CM-Sensors are specially designed for demanding applications: They withstand high pressures up to 100 bars (and more) at temperatures up to 190 °C. At conventional sensors with a similar size the probe head must be kept free from surrounding conductive objects, in order to avoid pre-attenuation of the measuring system. In contrast, the socket for the CM-sensor does not require additional notches or holes.This feature arises from the utilization of zirconium oxide as housing material and ferritic components with a focusing effect. The CM-sensor is typically applied to monitor the orbit of a turbocharger’s shaft.Its ball bearings have a squeeze film damper to reduce the rotor vibration. In order to optimize the entire system the CM-sensors detect the exact position of the turbine- and compressor wheel under real operating conditions.

Request for a quote

EDDYLAB GMBH

Germany

■ 1 and 2 channel drivers ■ Sensor protection class IP68 ■ Driver protection class IP40 or IP68 ■ Analog output ■ Low current consumption ■ High dynamics ■ High electromagnectic immunity

Request for a quote

MICRO-EPSILON

Germany

Inductive sensors from Micro-Epsilon are based on the eddy current principle and designed for non-contact measurement of displacement, distance, position, oscillation and vibrations. They are particularly suitable when high precision is required in harsh industrial environments (pressure, dirt, temperature). Inductive sensors from Micro-Epsilon offer extremely precise measurements where sub-micron accuracy is required.

Request for a quoteEPP ENERGY PEAK POWER GMBH

Germany

With an additional current transformer, the production data of the inverter can be recorded and visualized in the VARTA monitoring portal. As a result, you do not need a Solar-Log data logger to integrate the inverters.

Request for a quote

MICRO-EPSILON

Germany

The SGS (Spindle Growth System) 4701 displacement measuring system is developed for high speed milling machine applications. Due to high machining speeds and the heat generated, the linear thermal expansion of the precision machine tool spindle needs to be compensated for in order to keep the tool in a defined position at all times. The SGS sensor measures the expansion of the spindle caused by thermal and centrifugal force. The measurement takes places typically on the labyrinth-ring. As well as the linear expansion, the temperature of the sensor is detected and output.These measurement values are fed into the CNC machine tool as correction values, compensating for any positioning errors.

Request for a quote

MICRO-EPSILON

Germany

Modifying the standard eddyNCDT sensors is sometimes necessary particularly for small and large series. Therefore, we modify the measuring systems according to your specific requirements, e.g., changes to the cable, sensor material and design, and to the controller. In particular, sensors with integrated electronics in a miniature housing or special sensor designs are often requested by systems integrators.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8101.EC O-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system can be integrated in the flat layer section.

Request for a quote

MICRO-EPSILON

Germany

In its sensor housing, the combiSENSOR combines two displacement sensors. This unique sensor concept enables one-sided thickness measurement of electrically non-conductive materials on metallic objects. Its field of application is the thickness measurement of plastic film or of plastic coating on metal plates. The eddy current sensor penetrates the plastic layer and measures the distance to a metallic material underneath it, e.g. a metal plate. The capacitive sensor synchronously detects the distance to the plastic material. The thickness is determined based on the difference of both sensor signals.

Request for a quote

MICRO-EPSILON

Germany

Non-contact eddyNCDT 3300 eddy current displacement sensors are designed for use in factory automation, for machine monitoring, for quality control and quality assurance. More than 80 differentes sensors models are available.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MICRO-EPSILON

Germany

The eddyNCDT 3005 is a compact inductive measuring system (eddy current) for precise displacement and position measurements. The system comprises a robust controller, a sensor and an integrated cable and is factory-calibrated either for ferromagnetic or non-ferromagnetic materials.

Request for a quote

MICRO-EPSILON

Germany

The eddyNCDT 3001 is a new, efficient, inductive displacement sensor based on eddy currents whose compact dimensions have to date only been reserved for inductive proximity switches. The temperature-compensated design provides high stability even in fluctuating ambient temperatures. The eddyNCDT 3001 comes with integrated electronics, offering an outstanding price/performance ratio and easy operation.

Request for a quote

MICRO-EPSILON

Germany

The system RTP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. As the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment. The profilometer corresponds to the TIP 8301 regarding its functionality. However, it has a different operators´ frontend and evaluation functions.

Request for a quote

MICRO-EPSILON

Germany

The FTS 8102.EC C-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system is designed as a C-frame and can be used as a traversing unit by using the linear axis.

Request for a quote

MICRO-EPSILON

Germany

The BTS 8101.EO O-frame is based on the combisensor principle. The system is equipped with a non-contact capacitive sensors and a Thrubeam sensor which are integrated in a traversing frame. The eddy current sensor measures the reference distance to the measurement roll‘s metal surface. The distance from the film surface is measured by the Thrubeam sensor. Together with the reference signal the film thickness is calculated. This combisensor principle allows extreme precise measurements.

Request for a quote

SCHNIEWINDT GMBH & CO. KG

Germany

Since the invention of the “Schniewindt grid” in 1902, we produce high voltage resistors and are thus among the pioneers in the electrical industry. Due to continuous development of our products and new developments according to the respective needs of the market, we are now one of the leading manufacturers of electric heating equipment, resistance equipment and sensors for current and voltage measurement

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The rectifier with built-in current sensor for fast turn-off is designed for the operation of electromagnetic devices. It ensures fast turn-on and turn-off. The rectifier with bridge circuit comprises a thyristor and timer. During overexcitation, the rectifier delivers bridge rectified output voltage before changing over to half-wave rectification. On the DC side, the output voltage is enabled by the built-in current sensor which measures the AC current of the connected motor. If the motor is stopped, the rectifier turns off on the DC side as soon as the current falls below the turn-off threshold. The turn-off voltage generated by the inductive load is limited. The rectifier is suitable for connection in parallel with AC motors. The current sensor must be wired into the motor current path in such a way that the current flow created when the motor operates in generator mode will not pass through the sensor. This is crucial to avoid delayed or impaired DC side switching.

Request for a quote

TAVRIDA ELECTRIC

Germany

Air insulated switching module incorporates a Tavrida Electric vacuum circuit breaker with a per phase actuator, housed in a corrosion resistant tank. Six main circuit bushings, made from UVstable polymer, are covered with silicone rubber bushing boots. Each bushing has builtin current and voltage sensors for protection, measurement and indication purposes. The outdoor switching module is equipped with six, high voltage bushings with embedded current and voltage sensors. Current sensing is performed by Rogowski coil sensors. Capacitive sensors are used for voltage measurement in all six bushings. Tavrida Electric manufactures small vacuum interrupters with extremely long mechanical and electrical lifespans. A specially designed axial magnetic field distribution provides even current density over the contact surface and significantly improves the vacuum's interrupting performance.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

▪ Analogue version ▪ 5-pin connection ▪ Can be used with all analogue Hydraulic Testers of the PPC series ▪ CAN version ▪ 5-pin SPEEDCON connection plug ▪ Housing: Aluminium (black anodised) ▪ Gaskets: FPM (Viton®) ▪ Accuracy (at 21 cSt): ±1 (% FS*) or ±1 (% of the displayed value) ▪ Pressure measurement connection: SMK20 (M16 x 2) ▪ Temperature measurement connection: M10 x 1 (standard screw plug) ▪ Calibration certificate on request ▪ UNF version on request Ambient Conditions ▪ Media temperature: -20 °C ... +90 °C / -4 °F ... +194 °F ▪ Ambient temperature: -10 °C ... +50 °C / +14 °F ... +122 °F ▪ Storage temperature: -20 °C ... +80 °C / -4 °F ... +176 °F ▪ Permissible particle size: < 10 Micron for SFM-015 < 25 Micron for others ▪ Viscosity range: 10 ... 100 cSt Electrical Data ▪ Response time: 50 ms ▪ Flow Turbine (analogue): A PPC-04/12-CAB3 (3 m / 9.84 ft) Connection Cable is needed to connect the sensor to the current Hydraulic Testers. A PPC-04/12-CAB5-EXT (5 m / 16.40...

Request for a quote

DRIESEN + KERN GMBH

Germany

Sensors for Water Quality Parameters pH/Temperature pH-Sense330 Conductivity/Temperature µS-Sense340 O2 Saturation/Temperature O2-Sense350 The Sense300 Series by Driesen+Kern GmbH consists of three models for different water quality parameters. Each sensor model also measures temperature thus ensuring precise and temperature compensated readings. Electronic circuits are entirely integrated into the stainless steel housing making it compact and entirely submersible. Of course, it can also be installed in the process assembly. The user himself can perform calibration and exchange the electrode on each model. Devices are available with analog, digital and switching output. Analog outputs are 0-1V/0-10V or 4..20mA in thre-wire or as 4-20mA current loop. Optionally, the sensors can be fitted with a relay output whose switching value will be factory-set, but can later be changed with the programming kit.

Request for a quote

GIGAHERTZ OPTIK GMBH

Germany

Measurement system for the color transmission of fibers and flux, spectrum and color of cw and pulse operated LEDs. Features:25 cm integrating sphere in CIE 127 total flux conform set-up, CCD-sensor spectralradiometer, LED current cw and pulse source, software

Request for a quote

NORIS GROUP GMBH

Germany

Non-contacting multi-channel stainless-steel speed sensor, eddy current principle. Due to its design and type approval according to DIN EN 50155 especially suitable for transport technology. Scanning of all electrically conductive materials (steel or aluminium). Insensitive against mechanical abrasion (metal chips). Robust and high quality housing: IP69 pressure-tight and individually tested at 5 bar (for details see technical data). Excellent vibration and shock resistance and double protection of the sensor head. Connection outlet straight or lateral; with protective tubing on request. Detection of very low speed (near zero speed).

Request for a quoteResults for

Current sensors - Import exportNumber of results

31 ProductsCountries