- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- complete manufacturing

Results for

Complete manufacturing - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

BÜRKLE GMBH

Germany

Sampling tube manufactured in a clean room specially designed for disposable use. Due to the blue colour, it is also perfect for use in the food, animal feed and pharmaceutical industries. The scaled sample container can be used for an exact measurement. After sampling, the container can be closed and is leakproof. The closed handle structure ensures secure handling. The sample container is available with 50 ml, 100 ml or 250 ml content. Depending on the design, container openings can be sampled from a diameter of 52 mm (2" barrel opening), 65 mm or 85 mm. This makes DispoDipper ideal for extracting samples from barrels, canisters and other containers. DispoDipper is completely manufactured in one piece and can be used for sampling and subsequent transport of the sample in one device. In this way, cross-contamination or sample impurities are impossible.

Request for a quote

SCHOLPP GMBH

Germany

Complete installation: services for machinery manufacturers. One part of our services is performing the same installation processes again and again, or complete installations of similar machinery by one manufacturer. To maximize speed, efficiency and quality, we familiarize one or several teams with the specific characteristics of your machinery. This means we are ideally placed to support your staff all the way from disassembly, through transport, to ensuring production readiness. Depending on the task in hand, we assemble interdisciplinary teams with specialists from a variety of fields, including mechanical engineering, mechatronics, electronics, and electrical engineering. And we carefully select equipment, with the best interests of your machines in mind. We guarantee that your machinery will be lifted at the correct points and be up and running as soon as possible. SCHOLPP can train one or more teams on the specific characteristics of your machinery on request.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Our range of vandal resistant pushbuttons is very wide to offer you the best possible choice. With our handy configurator you can quickly and easily put together the perfect pushbutton for your needs and request it directly. New: an individual engraving of the push-button cover is possible for push-buttons of the S1AGQ series with mounting diameters of 16mm, 19mm and 22mm. In addition to the individual configuration of our three basic series, we also offer you the option of manufacturing completely customized pushbuttons in individual colors, engravings and adapted technical specifications. Simply send us your desired requirements by e-mail. Our engineers will configure your suitable pushbutton and send you an offer. If you have any questions, we will of course be happy to answer them and provide you with comprehensive advice on selecting the right pushbutton for your application.

Request for a quote

TEPROSA GMBH

Germany

Baking varnish is a special joining technology for sheet metal packages. After the individual lamellas have been cut, electrical steel with a baking varnish coating is baked into a sheet metal package in a two-stage temperature step. The result is a full-surface, solid connection between the individual sheets with complete insulation. Sheet metal packages manufactured in this way have high precision and perfect magnetic properties. Advantages of the Backlack process: The Backlack process offers several advantages over alternative packaging processes, which we will discuss in detail below. Precision – Sheets coated with baking varnish are baked over the entire surface. This means that even delicate slats can be assembled precisely.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction, rolling and pivoting bearings, splined shafts, knockout spindles and sliding surfaces of all kinds under heavy loads and a broad temperature range, as well as all sliding speeds permissible for grease lubrication Advantages and benefits Modern grease with a wide range of applications Supports sealing of bearings Good corrosion protection Resistant to ageing and oxidation Good resistance to pressure and water Available in the 120 cm³ ChronoLube cartridge For optimum effect, carefully clean the lubricating point, for example with OKS 2610/OKS 2611 universal cleaner. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value < 50,000) and their housings should be filled completely. The bearing and machine manufacturer's instructions should be observed. Subsequent lubrication

Request for a quote

BVS ELECTRONICS GMBH

Germany

Lenze drive technology Regardless of whether you require motors, gear units or specific drive elements, we have an extensive selection of products manufactured by Lenze to meet your exact requirements. This includes frequency converters and servo motors as well as various accessories, such as signal and power cables, function modules, handheld terminals and mounting kits. We not only complete repairs for products manufactured by Lenze but also sell and service these modules.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of friction, rolling and pivoting bearings, splined shafts, knockout spindles and sliding surfaces of all kinds under normal loads and all sliding speeds common for grease lubrication Supports sealing of bearings and corrosion protection Advantages and benefits Highly effective due to optimum combination of components Good resistance to pressure and water Fewer downtimes and repairs as a result of reduced wearing Resistant to ageing and oxidationFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610/OKS 2611 universal cleaner. Before filling for first time, remove anti-corrosion agent. Fill the bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value < 50,000) and their housings should be filled completely. The bearing and machine manufacturer's instructions should be observed.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Lubrication of parts subject to high levels of stress such as plain, roller and rod-end bearings, spindles and guideways Advantages and benefits Highly suitable for high-stressed lubrication points Highly effective caused by optimal combination of components Saving of maintenance and lubrication costs by reducing downtimes and corrective maintenance Reduction of down times due to wearFor highest effectiveness, carefully clean the lubrication point, for example with OKS 2610 or OKS 2611 universal cleaner. Before filling for first time, remove anticorrosion agent. Fill bearing such that all functional surfaces are certain of being greased. Fill normal bearings up to about 1/3 of the free space inside the bearing. Low-speed bearings (DN value below 50 000) and their housings should be filled completely. The bearing and machine manufacturer´s instructions should be observed. Subsequent lubrication at the lubrication nipples by grease gun or by automatic lubrication system.

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

Due to the ever-increasing level of automation, coated rolls and rollers are now used in almost all production facilities. These rollers and rolls are used in a wide variety of applications (transport, finishing, cleaning, coating, drying, etc.). What is particularly important is the quality of the coating, which determines the service life of the roller and the processing process.We manufacture completely coated rollers, i.e. We provide you with the roller core made of aluminum, steel, etc. and the desired coatings (rubber, Vulkollan®, etc.) from a single source. We can also roughly pre-grind your rollers, finely grind them or even provide them with grooves.As a cost-effective alternative, we also offer you to have your rollers recoated by us. Here too we can choose between different coatings (rubber, Vulkollan®, etc.). According to the customer’s wishes, we can also pre-grind, finely grind or provide these rollers with grooves. We would be pleased to advise you!

Request for a quote

SPIROL

Germany

The SPIROL Model PH Heat Insert Driver provides an accurate and consistent method to simultaneously install multiple Threaded Inserts or Compression Limiters at multiple elevations. Simultaneous installation dramatically increases productivity and simplifies the number of manufacturing steps to complete an assembly. Additionally, the platen head and fixture can be easily changed to accommodate quick change-over to different assemblies associated with new production runs. This machine can be used to install 12 Inserts into 1 assembly, or a fewer number of Inserts into a larger number of assemblies – as long as the total combination does not exceed 12 Inserts.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quote

SCHMIDT ZERSPANUNGSTECHNIK GMBH

Germany

Our workshop is equipped with CNC boring mills SCHMIDT Zerspanungstechnik's modern machinery offers a variety of options when it comes to the contract manufacturing and machining of work pieces and large machine parts. As a reliable machinist of large parts, SCHMIDT Zerspanungstechnik relies on state-of-the-art CNC boring mills whose complex movements are controlled by computer and which can be programmed. The employees working in our machine shop have modern 5-axis boring mills with axis travels of 3,500 x 2,000 x 1,500 mm at their disposal. They allow us to perform heavy-duty machining jobs as well as all other typical milling work. Our complete mastery of this flexible manufacturing process guarantees high-quality results are achieved in the most efficient way.

Request for a quote

BUSS-SMS-CANZLER GMBH

Germany

Systems & Modules SMS designs, manufactures and supplies complete systems & modules for evaporation, drying and membrane applications. Our scope of supply includes: Consulting / Feasibility Studies Pilot Test Process Design Plant Engineering Project Management Procurement / Manufacturing / Delivery Erection / Installation Start-Up / Commissioning After-Sales Service Skid-Mounted Modules For more than 40 years SMS has been supplying skid-mounted units for the benifit of our customers. The skids are fully assembled, including piping, wiring and testing in the SMS Workshop or in our partners´ workshop. The modular design significantly reduces the required amount of work for assembly and start-up which minimizes the downtime of the existing plant equipment and - as a result - just minor effects occur on the current production.

Request for a quote

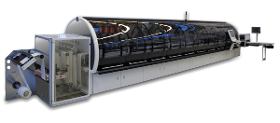

RUHLAMAT GMBH

Germany

The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio. The system can be designed to perfectly match your needs: sheet to sheet (S2S), reel to sheet (R2S), or reel to reel (R2R). This flexible solution offers the most economical way to produce RFID inlays for ID documents in large quantities. You get unrivalled real-world throughput: up to 4,050 antennas/hour as antenna embedding machine and up to 2,000 finished RFID inlays/hour as inlay manufacturing line. The WCE2000 is available in virtually unlimited configurations. Wire coil embedding, module pick & place, soldering, and testing are the main features that can be integrated to build a tailor-made solution. Punching, sheet cutting, handling and collation of additional layers, and other features complement the system to a complete inlay manufacturing line. The possibility to combine all of...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF manufacturers a complete range of Mobile Filtration Systems. Compact in design and easy to operate on the one hand, but also made for permanent use with high flow rates on the other hand, Mobile Filtration Systems are essential tools for the preventive maintenance either to transfer new oil or to purify hydraulic and lubrication oil systems Replacement Filter Elements ▪ Filter Elements of the NR-630 series ▪ Micron rating available from 3 ... 25 μm Clogging Indicator ▪ STAUFF Clogging Indicator Type HI Construction ▪ Mobile filter system - mobile filter unit Weight ▪ SMFS-U-060: approx. 165 kg / 364 lbs ▪ SMFS-U-110: approx. 177,2 kg / 391 lbs ▪ SMFS-U-CM-110: approx. 220 kg / 485 lbs Nominal Flow Rate ▪ SMFS-U-060: max. 60 l/min / 15 US GPM ▪ SMFS-U-110: max. 110 l/min / 30 US GPM ▪ SMFS-U-CM-110: max. 110 l/min / 30 US GPM Motor ▪ 400 V AC 50 Hz ▪ SMFS-U-060: 2,2 kW; 1440 U/min ▪ SMFS-U-110: 4 kW; 1445 U/min ▪ SMFS-U-CM-110: 4 kW; 1445 U/min Media Compatibility ▪...

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel rod, which is manufactured completely from stainless steel (Ø 42 mm), is used to install building components and (sub)structures on a roof surface. Our ABS UniMount is a flexible solution which can be used to install solar panels and photovoltaic modules, air conditioning systems and similar components. It can can either be installed on a concrete or steel surface. Base plate (130 x 130 mm) + welded-on mounting rod (Ø 42 mm) Female thread (M 10) at the top end For steel surfaces with a depth of at least 5 mm For horizontal and vertical loads of max. 3 kN Incl. stainless steel installation set

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

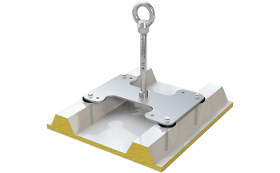

ABS SAFETY GMBH

Germany

This anchorage point (Ø 16 mm) for sandwich sheeting is simply installed from above using 4 special toggle bolts. The anchorage eyelet, rod and base plate (372 x 200 mm) are all manufactured completely from stainless steel material. The special toggle bolts needed are included in the package. EN 795:2012, A + CEN/TS 16415:2013 Sandwich and trapezoidal sheeting (negative) For steel plating ≥ 0.5 mm Distance between the bores: 280 to 333 mm Installation materials included Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

This anchorage point (Ø 16 mm) and its base plate (100 x 100 mm) are manufactured completely from stainless steel. The device is simply screwed permanently onto a wooden beam. It is available in different lengths and comes with the 4 stainless steel screws required for installation. EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Min. beam dimensions: 100 mm x 120 mm Incl. installation set Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Protect the upper thread and Data Matrix code of your ABS-Lock III-BE anchorage point from deformation through accidental hammer damage. Before hammering your anchor into place, simply screw this extension piece on top of the thread - and remove it afterwards to make room for your anchorage eyelet. Protects your ABS-Lock III-BE thread and Data Matrix code from accidental hammer damage Manufactured completely from stainless steel material

Request for a quote

PROTEC POLYMER PROCESSING GMBH

Germany

ProTec offers complete production systems for manufacturing long-fiber reinforced thermoplastics (LFT) in pellet form and as UD tapes (unidirectionally reinforced tapes) as well as impregnated fiber strands and profiles. The system works extremely flexibly and is designed for variable formulations and high throughputs at a production speed of 50 m/min. We deliver an LFT system design customized to meet the respective customer requirements, all from an single source – from material development, to testing and commissioning on location at the customer‘s premises.

Request for a quote

SERVOLIFT GMBH

Germany

Lifting, transporting and tilting drums and bins is a typical task especially in the chemical and pharmaceutical industrie as well as in food manufacture. SERVOLIFT, the original handling system, has been manufactured for approximately 30 years. It provides decisive advantages thanks to its two arms: unhindered view of the transport materials, exact and safe operation, uncompromising compliance with all hygiene requirements as well as a higher degree of reliability and cost effectiveness. Strong, maneuverable and easy to operate: the new SL 250 Technical description Free view of the carried load Loads up to 350 kg Explosion protection for zones 1/21 and 2/22 Lift up to 4,250 mm GMP-compliant construction, easy to clean and completely manufactured of stainless steel Faster and easier exchange of the gripper system for various drum types Space-saving due to its very compact design Very maneuverable in confined spaces Can be used everywhere due to its low weight Extendable versions...

Request for a quote

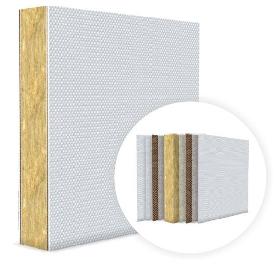

CBG COMPOSITES GMBH

Germany

Fire-resistant composite sandwich panel based on basalt and ceramic. CBG SeaPan WP 25/15 offers completely new solutions to the manufacture of cabin walls and bulkheads in shipbuilding, residential and office containers in construction sphere. The use of lightweight composite materials (e.g. with only approx. 7.99 kg/m2 for a wall panel of fire class A-30) makes it possible to significantly reduce the total weight of a construction. ✓ 100% natural and chemically neutral ✓ antibacterial ✓ corrosion-resistant ✓ thermoresistant ✓ pressure-resistant ✓ water-repellent ✓ reduce vibration ✓ fire-resistant ✓ nonflammable ✓ recyclable

Request for a quote

CBG COMPOSITES GMBH

Germany

Fire-resistant composite sandwich panel based on basalt and ceramic. CBG SeaPan WP 15/15 offers completely new solutions to the manufacture of cabin walls and bulkheads in shipbuilding, residential and office containers in construction sphere. The use of lightweight composite materials (e.g. with only approx. 5.7 kg/m2 for a wall panel of fire class B-15) makes it possible to significantly reduce the total weight of a construction. ✓ 100% natural and chemically neutral ✓ antibacterial ✓ corrosion-resistant ✓ thermoresistant ✓ pressure-resistant ✓ water-repellent ✓ reduce vibration ✓ fire-resistant ✓ nonflammable ✓ recyclable

Request for a quote

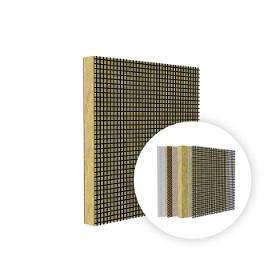

CBG COMPOSITES GMBH

Germany

CBG SeaPan WP 15/G offers completely new solutions to the manufacture of cabin walls in shipbuilding. The use of lightweight composite materials makes it possible to significantly reduce the total weight of a construction with e.g. only approx. 5,25 kg/m2 for a wall panel of fire class B-15. A special feature of this panel is its excellent sound insulation. — 100% natural origin, chemically neutral — non-combustible — no smouldering — no smoke emission in case of fire — antibacterial — corrosion-resistant — pressure-resistant — vibration damping — recyclable — water repellent — good air permeability — thermoresistant

Request for a quote

CBG COMPOSITES GMBH

Germany

CBG SeaPan WP 25/G offers completely new solutions to the manufacture of cabin walls in shipbuilding. The use of lightweight composite materials makes it possible to significantly reduce the total weight of a construction with e.g. only approx. 7.8 kg/m2 for a wall panel of fire class B-15. A special feature of this panel is its excellent sound insulation. — 100% natural origin, chemically neutral — non-combustible — no smouldering — no smoke emission in case of fire — antibacterial — corrosion-resistant — pressure-resistant — vibration damping — recyclable — water repellent — good air permeability — thermoresistant

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Safe storage and transport: Siempelkamp is your container manufacturer for heat-generating and non-heat-generating radioactive materials Wide range of designs for all classes We produce a variety of containers for handling radioactive materials of all classifications. The choice of materials ranges from the use of different casting qualities to granulated concrete and steel. The range of services is completed by the authorization to carry out type tests. For more than 30 prototype types, the required certificates of qualification for the transport and storage of the casks have already been successfully completed in our manufacturing facilities. CASTOR ® casks bodies CASTOR ® casks are used as transport and interim storage containers for fuel elements and high-level radioactive waste.

Request for a quote

A. EBBECKE VERFAHRENSTECHNIK AG

Germany

Screening The right screening procedure for any size and virtually any bulk material Ebbecke Verfahrenstechnik AG has the right plants and a know-how developed over decades for the best screening results with virtually any bulk material. For this reason, customers come to us for contract screening from the cosmetics, pharmaceutical, food, chemical and animal feed industries. Cutting-edge technology As a contract screening company active for many years we know what the priorities are for our customers. For these needs, we have self-developed our contract screening plants from Planoscreen and Planodry types. With these advanced contract screening plants not only can we screen contaminate-free , we can at the same time dry the screened product under a nitrogen atmosphere or a pressure cascade. In addition to the machines and process engineering plants that we have developed we also screen on systems from other manufacturers. For this completely different screening procedures are used d

Request for a quote

WITT-GASETECHNIK GMBH & CO KG

Germany

WITT offers high-quality gas mixers / gas blenders and gas metering systems for two or more gases, for high flow rates and highly fluctuating gas withdrawals. You can choose between various options: According to your requirements, WITT gas mixers / gas blenders are available for nearly all technical gases and flow rates: for the optimal gas mixture for welding applications, the required gas concentration for food packages (modified atmosphere packaging = MAP) or the production of synthetic air for medical applications. State-of the art mechanical or electronic gas mixing systems provide accuracy and process safety. You can also control your gas mixing systems conveniently via Intranet, Internet or mobile devices. Combinations of WITT gas mixers / gas blenders with other WITT quality products such as gas analysers are also possible. They can be manufactured as complete system solutions.

Request for a quoteResults for

Complete manufacturing - Import exportNumber of results

34 ProductsCountries

- Germany (34)

- Bonn, Düsseldorf and North Rhine and Westphalia (17)

- Frankfurt am Main and Hesse (5)

- Hamburg and region (1)

- Magdeburg and Saxony-Anhalt (1)

- Mainz and Rheinland-Pfalz (1)

- Munich, Nuremberg and Bavaria (4)

- Saarbrücken and Saarland (1)

- Stuttgart, Freiburg and Baden-Wurtemberg (3)

- Weimar and Thuringia (1)

Company type

Category

- Flame retardant construction materials (4)

- Silicones (3)

- Laser - cutting and welding machines (1)

- Automation - systems and equipment (1)

- Erection and dismantling of industrial plants (1)

- Gas mixtures (1)

- Goods handling systems, continuous (1)

- Industrial sheet metal work (1)

- Machinery and equipment, used and reconditioned (1)

- Milling - steels and metals (1)

- Plastics - machines and material for industry (1)

- Quality control and certification (1)

- Sawmills - machinery and equipment (1)

- Screw cutting - steels and metals (1)

- Switches (1)

- Transportation, bulk (1)

- Wheels, castors and rollers (1)