- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping tools

Results for

Clamping tools - Import export

IGUS® GMBH

Germany

Easy rope tension For splitted drive wheel RL-ZA011-0250 Material: PA2200 / VA Prices upon request robolink® multi-axis joint robolink® Configurator DryLin® drive systems

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Double-acting pneumatic cylinder for integrated installation in clamping tools.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Mount tools safely and in the correct position while remaining flexible, all this is possible with the UMB100 mounting unit. The tool clamping units can be changed quickly, making the system an ideal mounting aid for multi-tasking machines. It only takes a few seconds to replace an adapter. The unit with snap-in swivel can be pivoted 4 x 90° at the touch of a button so that even angled holders can always be mounted in the ideal position. Universal mounting block UMB100 Tool holder for VDI holding fixtures Tool holder for Varia VX Tool holder for steep-angle taper holding fixtures

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

The rapid change system EWS-Varia allows to set-up a modern CNC lathe or a turning milling center – and this flexibly. A tool change will just take 20 seconds, which is an unbeatable argument especially in small batch productions whenever it is about reducing the set-up time and thus increasing the productivity. The advantages, however, are also evident in large batch productions. Preset twin tools lie at the machine, thus significantly reducing the down-times. A further advantage is provided by the variety of adaptations; so the optimal tool clamping can be selected for each operation. The inserts available include: Collet chuck holders Weldon/Whistle Notch Milling arbors Morse tapers Hydro extension Shrink adaptations The most important advantage is certainly created by the easy handling. The inserts can be changed with just one hand without counter pressure by the spindle.

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Driven tools form a further core area of EWS. More than 8,000 different tools are available at short notice. In addition to standard products like axial and angular heads, EWS offers swivel units, slot broaching tools, multiform tools and multi-spindle machines. There is just no limit. The tool clamping systems range from the classic collet chuck holder to Weldon and hydro extension to Capto, KM, ABS and HSK. The applications range from classic CNC lathes to highly complex turning milling centers. The rapid change system EWS-Varia has set a standard for a flexible modular system. With its safe handling and short change-over times, EWS-Varia ranks among the most successful systems in the market. This was impressively confirmed by the Innovation Award awarded by the German state of Baden-Württemberg in 2006. "Made in Germany" is of course guaranteed by EWS also for these tool systems.

Request for a quote

IGUS® GMBH

Germany

d1: robolink® multi-axis joint robolink® Configurator DryLin® drive systems Tensible robolink® drive wheel Splitted design Same measures as RL-ZA001-0250 Easy-tensioning of the drive ropes Releasing and clamping with hexagon socket Optional with igus® clamping tools d1:

Request for a quote

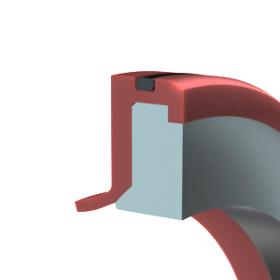

IDG-DICHTUNGSTECHNIK GMBH

Germany

Motor shafts. Gear and frive unit shafts. Fan shafts. Clamping tools. Applications at high speed and lo pressure.

Request for a quote

MICRO-EPSILON

Germany

The LVP-25-Z20 and LDR-14-Z20 sensors are used for monitoring the clamping position in machine tools. These inductive sensors are integrated in the release device and directly measure the clamping stroke of the drawbar onto which the target ring is glued. Due to their extremely compact design, these sensors are used for different types of tools while providing high-precision and continuous monitoring. No adjustment is necessary when changing the tool.

Request for a quote

WEBER FOOD TECHNOLOGY GMBH

Germany

Combination machine for thick and thin: The AMS 533 TWIN skinning machine is particularly suited to processing cuts with thick tendonsand skin, such as pork loin, pork silverside, beef or veal silverside and boiled beef fillet. Advantages Removal of tendons and skin with one machine TWIN transport rollers and specially coordinated blades providethe highest possible yields Ideal cutting width for powerful skinning and tendon removal inlarge and small cuts Effort-saving work table design due to ergonomicmachine assembly Blade guard in cleaning position Gear brake motor with quick stop Product-specific precision adjustment Options: Quick-clamp blade holder for tool-less blade changing Body lever switch Skinning procedure protection Skinning gloves Special tension rollers

Request for a quote

HONSEL-GROUP

Germany

HONSEL ALFO® FLEX blind rivets have been specially optimised for often problematic riveting in very soft materials or with slightly too large drill hole diameters. Due to the thinner wall thickness of the blind rivet sleeve, less force is required to deform the blind rivet sleeve. This improved deformation leads to a higher residual rivet mandrel locking. A thinner wall thickness of the blind rivet sleeve also means less influence on the hardening fluctuations caused by the annealing process. Result: The riveting function is much more consistent compared to conventional rivets. On request, the material combinations steel/steel and stainless steel/stainless steel (A2 and A4) are available as flat, countersunk or large heads. large head with a corresponding minimum quantity. Why ALFO® FLEX . Compensation for excessively large drill holes . improved residual mandrel locking . lower breaking forces . less wear on the tool . higher clamping force . ideal for soft material

Request for a quote

HONSEL-GROUP

Germany

The HONSEL COIL "cone" can be installed in the same way as a coil with tab. No additional or special tools are required for process-reliable installation. When the HONSEL COIL "cone" is screwed onto the installation spindle, the conical portion of the wire thread insert creates a clamping effect between the installation tool and the coil. This ensures a stable installation process into the work piece. Advantages: — tab-free and therefore optimally designed for e-mobility due to no risk of tab debris. — Shallower blind hole depths can be realized — Subsequent processes are no longer necessary (breaking and removing of the installation tab) — No thread skipping during installation — Cycle time reduction of 20-30 % per installation — No special tools required for the installation process — The installation process improves due to the conical portion

Request for a quote

RONIX GMBH

Germany

The Ronix RH-1440 sheet metal locking plier is a quality product from the varied collection of Ronix hand tools and sheet metal pliers. This tool is used to hold and move sheet metal, bend the corners of workpieces, curve the edges of parts, and clamp and hold sheet metal to be welded while working. The Ronix RH-1440 8-inch sheet metal clamp is made from high-quality stainless steel. In addition, its wide, machined, standard-size jaws are designed to hold the part in position. The clamping force of this tool is evenly distributed, so the sheet metal is not damaged during transport

Request for a quote

ORBITEC GMBH

Germany

Tube squaring machines are necessary to achieve burr-free and right-angled seam preparation for orbital welding. That‘s why Orbitec offers two machines, from the small handy Planfix 40 S to the large Planfix 115 S. The Planfix 115 S is a high-performance tube squaring and chamfering device with angle gear for mobile or stationary use with a mains drive. It has a large viewing window, a chip collector and a feed with 0.1mm scale graduation. Optionally, the device can be equipped with a tool carrier and a double-sided indexable insert holder or the well-known Orbitec L facing tool bits. Package includes exemplary for Planfix 115 S Power 230 V: — Tube clamping attachment — Drive — Tool set — Transport box

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Hand piece ESS 3-50 (Slim) ***SE 50 Silent Grinder *** The new micro grinder with electric mickro-motor from BIAX - lightweight, low Vibration, extremly low noise! Technical data of hand Piece: Diameter: max. Ø 29 mm Length: 162 mm Weight without cable: 240 gr Run-out accuracy: < 0,02 mm Collets diameter: 3,0 mm (standard) / 2,35 mm (optional) Tool changing: Quick clamping Cooling: Enclosed (all models) Drive system: Brushless DC motor (all models) Technical Data: Speed range: 1.000 - 50.000 rpm Operating Voltage: 100 - 240 Volts Rated frequency: 50/60 Hz Power: 150 Watts Overload protection: Eliminates waiting time when switching back on Direction of Rotation: Switch between clockwise and anti-clockwise rotation

Request for a quote

BIAX - SCHMID & WEZEL GMBH

Germany

Hand piece ESB 3-50 (Basic) ***SE 50 Silent Grinder *** The new micro grinder with electric mickro-motor from BIAX - lightweight, low Vibration, extremly low noise! Technical data of hand Piece: Diameter: max. Ø 30 mm Length: 165 mm Weight without cable: 240 gr Run-out accuracy: < 0,02 mm Collets diameter: 3,0 mm (standard) / 2,35 mm (optional) Tool changing: Quick clamping Cooling: Enclosed (all models) Drive system: Brushless DC motor (all models) Technical Data: Speed range: 1.000 - 50.000 rpm Operating Voltage: 100 - 240 Volts Rated frequency: 50/60 Hz Power: 150 Watts Overload protection: Eliminates waiting time when switching back on Direction of Rotation: Switch between clockwise and anti-clockwise rotation

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

HAND-Demagnetizers be used for degaussing of large parts or workpieces, which cannot be done to the device for other reasons, for example, Injection molds, stamping tools, vices built, clamped tools, etc. This portable model can be used for a maximum of 10 minutes of continuous operation. It is equipped with a thermostat that switches it off when the maximum permitted temperature (60ºC) is reached; it can only be used again once the temperature has dropped. The device is moved by hand over the workpiece, as close as possible to the surface, but without touching it.

Request for a quote

FRIMO GROUP GMBH

Germany

Successful for decades and constantly evolving Regardless of the desired kinematics, clamping force or clamping area, FRIMO customized tool/mold carriers can be integrated into single-station or multi-station units, rotary table systems or PURe Track overhead conveyors. FRIMO's more than 1,000 manufactured and delivered tool/mold carriers serve as proof of superior quality and reliability. Special Types: FRIMO is your specialist when it comes to optimal tooling concepts based on customer demands. Our product portfolio covers a broad spectrum of possible special designs, such as window frames, damping units, cast skins, skis, acoustic components, boilers, glass roofs, steering wheels, seat cushions and head rests.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TAS SCHÄFER GMBH

Germany

Use full screen mode The main function of the rigid flange coupling (FKE) is the safe and backlash-free connection of two shafts by means of friction. For example, between a drive shaft and an agitator shaft. Flange couplings are directly separable at the flanges. The used pressure ring generate a backlash-free connection by pressing the flange-hubs onto the shafts. This connection is mainly used to transmit torque. It can also be transmitted axial forces and bending moments. The shrink connection do not transmit any forces and/or moments between the shafts and hubs, they just provide the necessary forces. They are not in the flow of forces. It is installed by sliding the flanges onto the shaft ends and subsequent tightening of the pressure ring. Thereafter the flanges are connected by bolting. The rigid flange couplings are supplied ready for installation. The clamping is done manually by means of screwing tools. Optionally with a hydraulic clamping tool. To achieve proper...

Request for a quote

STARRAG GMBH

Germany

The Bumotec s1000 C horizontal transfer machine was designed to manufacture prismatic parts from round or profiled bar stock. Small and complex components can be efficiently machined in medium to large batch sizes. The machine is configured with seven 4axis machining stations, each equipped with 4 machining spindles (2 horizontal and 2 vertical). The eight stations comprise a 4axis cut off station with a single spindle. An optional ninth station allows the component to be reclamped to allow the sixth side of the component to be machined with an additional 3axis, 3 or 4 spindle machining unit. The machine is equipped with an automatic bar feed and quick change tool clamping system for optimum production rates. Features 9 machining stations Up to 36 tools integrated into the machine

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application The VD2 is designed to reface valve seats of the engines of trucks. heavy construction vehicles and small ships. Features The VD2 refaces the valve seat in a lathe-type facing action. The tool head includes two inclined slideways for refacing 30° and 45° valve seats. A single point turning tool is clamped to tool slide guided in the respective slideway. When the VD2 is rotated around the pilot by hand, the turning tool travels in a circle around the valve seat with continuous outward transverse feed motion under the correct seat angle. A steady rest which is mounted on the cylinder head stabilizes the VD2 below the crank handle. The steady rest eliminates runout when rotating the VD2 around the pilot. As a result, the seat is refaced to concentricity with the valve guide under the correct seat angle.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Standard clamping technology from AMF: versatile, durable, reliable. The highest level of quality applies to this exceptional versatility as well. Every product meets the demand for innovation and the specific requirements within the scope of practical application.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Zero-point clamping technology from AMF: economical, strong, precise. The Zero-point system from AMF has virtually revolutionised the zero-point clamping technology market with technological superiority. The highly precise clamping modules with high draw-in, locking and holding forces ensure perfect clamping in the widest range of applications.

Request for a quote

ANDREAS MAIER GMBH & CO. KG (AMF)

Germany

Toggle clamps from AMF: versatile, strong, durable. Tried-and-tested technology with ever new variants. The benefits of our toggle clamps are highly valued in many fields of application: in the metal industry for drilling, welding, bending, grinding, checking and mounting as well as for the machining of wood and plastic in gluing, drilling, cutting and milling fixtures.

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-4/90 P=30 kW, n=3,000 RPM, M=1,000 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with internal and external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 515 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-2/90 P=15 kW, n=1,500 RPM, M=500 Nm Construction principle: - Positioning and clamping: manual - SK 50 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1.68 : 1 - Manufactured length (up to spindle centre): 750 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description manual single-axis milling head KF-1/90 P=7 kW, n=3,500 RPM, M=150 Nm Construction principle: - Positioning and clamping: manual - SK 40 without automatic tool clamping - with external coolant supply - Lubrication: grease lubrication - Transmission gear: 1 : 1 - Manufactured length (up to spindle centre): 495 mm / 645 mm - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC-single-axis positioning milling head KF-D2/90 P=13 kW, n=1,500 RPM, M=400 Nm Construction principle: - NC positioning lift-off milling head with hirth serration ring - Positioning the main spindle of the machine - SK 50 with automatic tool clamping - with external coolant supply - Lubrication: grease lubrication A-axis / Axis 2 (90°) - Swivel range: n x 360° - Pitch: 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 7,500 Nm Accuracy - Concentric running of the internal cone: L=15 mm : 0.010 mm L=315 mm : 0.030 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC-two-axis positioning milling head KFU-D8/90/X P=80 kW, n=2,000 RPM, M=2,600 Nm Construction principle: - NC positioning lift-off milling head with hirth serration ring - Positioning the main spindle of the machine - SK 50 (HSK 100) with automatic tool clamping - with internal and external coolant supply - Lubrication: minimum oil/air lubrication - Option: axis measurement system C-axis / Axis 1 (90°) - Swivel range: n x 360° - Pitch: 360 x 1° / 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 12,000 Nm A-axis / Axis 2 (90°) - Swivel range: n x 360° - Pitch: 360 x 1° / 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 10,000 Nm Accuracy - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteSEMPUCO WERKZEUGMASCHINENFABRIK GMBH

Germany

Description NC-two-axis positioning milling head KFU-D8/45/X P=80 kW, n=2,000 RPM, M=2,600 Nm Construction principle: - NC positioning lift-off milling head with hirth serration ring - Positioning the main spindle of the machine - SK 50 (HSK 100) with automatic tool clamping - with internal and external coolant supply - Lubrication: minimum oil/air lubrication - Option: axis measurement system C-axis / Axis 2 (90°) - Swivel range: n x 360° - Pitch: 360 x 1° / 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 12,000 Nm A-axis / Axis 2 (45°) - Swivel range: n x 360° - Pitch: 360 x 1° / 144 x 2.5° - Positioning accuracy: ± 3" - Tangential stress: 10,000 Nm Accuracy - Concentric running of the internal cone: L=15 mm : 0.010 mm L=300 mm : 0.020 mm - Centre offset : 0.020 mm

Request for a quoteResults for

Clamping tools - Import exportNumber of results

44 ProductsCountries

Category

- Milling - machine tools (3)

- Industrial tools (2)

- Machine tools, metal machining - parts and accessories (2)

- Portable power sanders (2)

- Automation - systems and equipment (1)

- Industrial cutting machine tools (1)

- Magnets (1)

- Meat processing machines (1)

- Nuts and bolts (1)

- Paint mixers and grinding machines (1)

- Rivets (1)

- Sealing rings (1)

- Sensors (1)

- Tools, pneumatic (1)

- Vehicles - mechanical components and parts (1)

- Welding, soldering and brazing - equipment and supplies (1)