- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamping elements

Results for

Clamping elements - Import export

ACE STOSSDÄMPFER GMBH

Germany

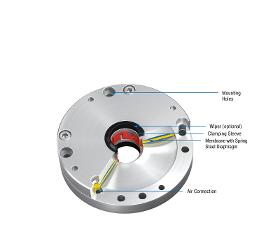

Pneumatic Rotational Clamping Holding torque 76 Nm Direct clamping on the shaft: Rotation motions are prevented by the ACE models LOCKED R. Their clamping elements are available for shaft diameters of 50 to 340 mm and ensure maximum holding forces. The clamp is immediately applied by the diaphragm and spring-plate system when pressure is lost. Pneumatic quick-switch valves reduce the reaction times. The costs are low in comparison with hydraulic clamping systems. Their performance is, however, achieved or exceeded despite the compact and easy to assemble design. Special versions for YRT bearings as well as active clamping elements are additionally available. ACE recommends the use of the optional shaft flange as wear protection. The clamping force can be increased considerably by the use of the additional air function.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

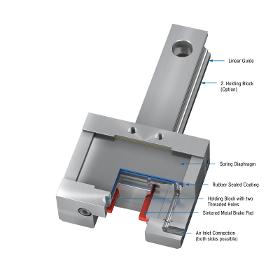

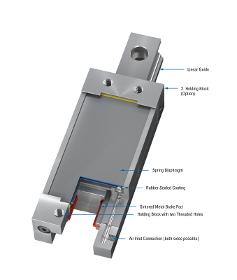

Safety Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family SLK clamping elements are more compact than the Series SL. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and safe. Thanks to the patented spring steel plate system, the product family SLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. Thanks to the sintered metal coatings and the clamping function in emergency stop (e.g. in case of a power failure), this range enables braking directly on the rail. All clamping elements offer the maximum holding and braking forces and achieve up to 1 million clamping cycles or up to a maximum of 500 emergency braking operations in the 4 and 6 bar version.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Safety Clamping for Rail Systems Holding force 540 N Always on the safe side: The safety clamping elements LOCKED SL clamp and brake directly on the clear area of guide rails on linear modules with forces of up to 10,000 N. They are individually adjusted to the linear guide being used and are available for all rail sizes from 20 to 65 mm and profiles from all renowned manufacturers. Special brake pads made of low wear sintered metal are used for the additional emergency stop braking functions in the safety clamping elements LOCKED SL. The SL product family offers optimum static clamping with a service life up to 1 million cycles or up to 500 emergency braking operations. They also offer low system costs in comparison with hydraulic and electric solutions.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Process Clamping for Rail Systems, Compact Holding force 300 N Small can clamp perfectly too: The LOCKED-Family PLK clamping elements are more compact than the Series PL components. They also clamp directly onto the respective linear guide, suit all standard rail sizes from 15 to 55 mm and profiles from the known suppliers and are extremely reliable and space-saving. Thanks to the patented spring steel plate system, the LOCKED-Family PLK achieves clamping and holding forces of up to 2,100 N with the shortest reaction times when vented. LOCKED PLK achieve 100 % clamping force due to the steel pads that are used, even on greased rails. The clamping elements represent the maximum holding forces. Whether in the 4 or 6 bar version, they are good for up to 1 million cycles.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Pneumatic Rod Clamping, Compact Holding force 700 N Holding torque 7 Nm Compact and safe: when space becomes restricted, the compact LOCKED PRK clamping elements come into their own. As pneumatic rod clamping with low heights of 28 to 34 mm, they provide clamping forces of up to 5,000 N. Clamping is carried out by a diaphragm spring-plate system and is released when compressed air is applied. Clamping elements from the LOCKED PRK product family absorb the forces on rods with diameters between 20 and 40 mm both axially and rotationally. The function makes them suitable for use as static clamping without pressure, because the failure or drop of pneumatic pressure triggers immediate clamping. High clamping forces with low system costs compared with hydraulic and electric solutions make these clamping elements particularly interesting.

Request for a quote

ACE STOSSDÄMPFER GMBH

Germany

Rail Clamping for Z-Axes Holding force 1,500 N Innovative and BG certified: The pneumatic clamping elements LOCKED LZ-P have been specially designed for safe, reliable clamping on the vertical or Z-axes. The wedge principle makes sure that the gravity loaded axis does not drop. The brake wedges are pushed on both sides against the flat parallel surfaces of the guide rail in case of a loss of pressure. Initially developed for Bosch Rexroth rails in sizes 15 and 25 mm, a test certificate from the trade association was awarded after extensive tests on these clamping elements. Further certifications from other rail manufacturers and sizes are prepared and can be implemented within the shortest time. Users achieve holding forces of up to 2,500 N.

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• side operation • low profile • with through-hole thread

Request for a quote

JAKOB ANTRIEBSTECHNIK GMBH

Germany

• high clamping forces - low tightening torques • with bottomed thread - thread protected • centered operation • compact design - up to 200° C (optional up to 400°C)

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

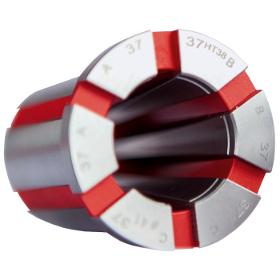

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

In terms of precision, stability, and flexibility the vulcanized segmented clamping bushings are unbeatable. They consist of segments made of chrome/nickel, case hardened steel that is very hard, extremely wear resistant, and rigid [60 HRC]. Plus, they do not have to »bend« to clamp the workpiece. In addition, all functional surfaces are completely ground in one clamping set-up. The result: maximum run-out accuracy, maximum holding power, and long life span.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

This development represents more than 30 years of SPANNTOP experience. It exploits all the advantages of the latest machine tools. This clamping head is not only extremely powerful, it is also convincing through simple handling. With the changing fixture you set up in no time. The combination of steel and rubber, specially developed by HAINBUCH, in conjunction with a vulcanization that has been perfected over decades, is designed for maximum speed and holding force – with optimal concentricity, and incredible rigidity and service life.

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

With our hexagonal clamping heads you get up to 25 % more clamping force and higher output with the same clamping cylinder actuating force that is used to actuate our SPANNTOP chucks. The pyramid arrangement of glide surfaces makes it possible. In addition the hexagonal geometry ensures that TOPlus is more resistant to contamination than former clamping head / chuck systems. Therefore, TOPlus is even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. With a concentric precision of ≤ 0.005 mm!

Request for a quote

HAINBUCH GMBH SPANNENDE TECHNIK

Germany

The segmented clamping bushing SE with the hexagon socket sits on the clamping pyramid, absolutely form-fitted in every clamping position and thereby enables maximum machining performance with minimal vibration and thus less tool wear. The full-surface contact of the segmented clamping bushing on the mandrel ensures a significantly better insensitivity to contamination than previous segmented clamping bushing/mandrel systems. Therefore, these segmented clamping bushings are even better suited for raw material, cast and forged parts, as well as fine-particle non-ferrous metals such as brass. And they offer this suitability at run-out of ≤ 0.01 mm and in the premium version at ≤ 0.007 mm.

Request for a quote

IGUS® GMBH

Germany

DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel DryLin® T - Technical data DryLin® T - Clearance adjustment DryLin® TWBM hand clamp DryLin® T - Design rules DryLin® T - Automatic clearance adjustment DryLin® linear guide systems in the cleanroom DryLin® T - Applications DryLin® T - System design DryLin® T - Installation videos System selection & service life calculation DryLin® T - Adjustable clearance The DryLin® T standard version is supplied preset and can be put into operation at once. The user can also manually adjust or fine-tune the clearance of the linear guide. The individual adjustment for your application, as well as the potential to respond to uneven screw surfaces through specific clearance allowance. DryLin® T - Adjustable clearance DryLin® T - Automatic DryLin® T carriages of the automatic version have a mechanism that automatically adjusts the bearing clearance after removal of the preload key. In case a bearing clearance of more than 0.13 mm has to be adjusted during operation, the bearing clearance automatically resets itself when the carriage is completely unloaded. DryLin® T - Automatic DryLin® TW-HKA manual clamp The manual clamp has been developed for simple tasks. The creep behavior of the clamped plastic causes a slackening in clamping force over time (up to 70%). Therefore safety-related parts should not be clamped. Please approach our applications consultant if you require other options for the clamping. DryLin® T - Manual clamping Drylin® T - Heavy Duty This series is used for the most extreme conditions such as dirt, adhesive residues, chips, mud, etc. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore non-detachable. This system is compatible with many standard commercial recirculating ball bearing systems and is available in the following sizes: TW-01-20, TW-01-25 and TW-01-30. DryLin® T Heavy Duty DryLin® T - Low-profile guide The clearance is not adjustable for the DryLin® T low profile guide rails. The gliding elements are mounted with positive fit in the chromated zinc carriage. This simple and effective design enables guides that are rugged and low-priced at the same time. DryLin® T - Low-profile guide DryLin® T - Compact linear guide This compact linear guide is suitable for rugged use (without clearance adjustment). This system has a slim design and the same dimensions as conventional recirculating ball bearing systems. The plastic gliding elements made of iglidur® J are fixed in the lid and are therefore undetachable. Suitable for DryLin® T guide rail of installation size 20. DryLin® T - Compact linear guide DryLin® TWBM - Manual clamping with high holding force This manual clamping is designed for a long-lasting high holding force of up to 500 N per clamping element. DryLin® TWBM hand clamp DryLin® T clamping elements for rail guide DryLin® T clamping elements for fast positioning by hand or with pneumatics. DryLin® T clamping element DryLin® T linear guide systems were specially developed for applications in automation and handling systems. The design objective was a rugged linear guide for application in the most diverse - and also extreme - environments. They have the same dimensions as most recirculating ball bearing guides. Technical data Gliding elements: Maintenance-free Material: iglidur® J * Max. surface speed: 15 m/s Operating temperature: -40°C to +90°C *Other materials on request 1 Profile rail and base body of the carriage made of aluminum. The rail is hard-anodized, the aluminum base body of the carriage is clear anodized. 2 Six gliding elements made of iglidur® J serve as guide bearings, which are positioned opposite to each other in pairs and make up 3 guide bearings. 3 Alternatively, bearing clearance is continuously adjustable 4 All steel parts are stainless steel 5 The lid is made of solid plastic or stainless steel Advantages: 100 % lubricant-free Adjustable bearing clearance Automatic clearance adjustment High static load capacity Service life up to 50,000 km without lubrication High dirt resistance Low vibration and low noise When not to use ? When you want to save installation space drylin® N drylin® W When you need a pure stainless steel solution drylin® W drylin® R When you want to construct as economical as possible drylin® N drylin® W

Request for a quote

IGUS® GMBH

Germany

drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis Single rail and housing bearing - round Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W single rail and housing bearing - round Single rail and housing bearing - angular Sizes: 6 mm, 10 mm, 16 mm and 20 mm DryLin® W single rail and housing bearing - angular double rail, round Sizes: 10 mm (rail width 40 mm, 74 mm and 120 mm), 16 mm (rail width 58 mm), 20 mm (rail width 82 mm) and 25 mm (rail width 120 mm) DryLin® W double rail Guide carriage, assembled Sizes: 10 mm, 16 mm, 20 mm and 25 mm DryLin® W guide carriage, assembled double rail, square Sizes: 06 mm (rail width 30 mm), 10 mm (rail width 40 mm and 74 mm) and 16 mm (rail width 58 mm) drylin® W double rail, square Mono-slide guide carriage Size: 10 mm Mono-Slide guide Single rail and housing bearing - round, adjustable Sizes: 10 mm, 16 mm and 20 mm Linear Guides with “Turn-To-Fit” Hybrid bearing WJRM drylin® roller bearings - Roll and glide for easy movement. drylin® W hybrid bearing | roller bearing hybrid bearing double WJRM drylin® double roller bearing - Roll and glide for easy movement. drylin® W hybrid bearing double Double rail, reduced weight Sizes: 6 mm (rail width 30 mm), 10 mm (rail width 40 mm and 80 mm) DryLin® W double rail, reduced weight Hybrid carriage with rollers Size: 10, 16 mm DryLin® W hybrid carriage with rollers Stainless steel guide V4A, individual Size: 20 mm DryLin® W stainless steel guide V4A - individual Stainless steel guide V4A - double DryLin® W stainless steel guide V4A - double drylin® W slider rails/carriages drylin® W rail profiles with 3/8" threads, complete rails with Ø 10 mm through bore, with/without hand clamps DryLin® W double rail, square Gliding elements For round and angular rails. DryLin® W - Gliding elements Manual clamp Developed for simple positioning tasks. DryLin® W - Manual clamp Digital measuring system With immediate digital indication of position. DryLin® W - Digital measuring system Hand clamp for higher forces Designed for positioning tasks with higher forces. DryLin® W hand clamp for higher forces DryLin® WKMEX digital measuring system with external output drylin® WKMEX measuring system with external output DryLin® SLW - the compact* Spindle-lift tables The extremely thin unit is based on a DryLin® W profile system, and its entire length is supported. This design offers an extremely high torsional stiffening simultaneously with compact dimensions. DryLin® SLW - Compact DryLin® ZLW Toothed belt axis For quick positioning of small loads. DryLin® ZLW - Toothed belt axis drylin® W - Advantages Dirt-resistant Weight saving Lubrication-free High speed Silent and light weight drylin® W - Advantages drylin® W - technical properties The technical properties of the drylin® W profile guide system Technical properties drylin® W - configuration Find the right profile guide system in 4 simple steps with the system and life calculation. drylin® W - configuration

Request for a quote

EZM EDELSTAHLZIEHEREI MARK GMBH

Germany

EZM Profiline – This EZM brand name stands for cold-drawn standard sec-tions and special sections to customer drawings in virtually all steel materials. Optimum heat-treatment, pickling and coating facilities are available for every material group. As a result of the continuous improvement of our in-house tool production operations, EZM can manufacture sections whose geometry and shape are as near as possible to the net shape, maintaining the tightest tolerances and producing flawless surfaces. Our cold-drawn sections are successfully used when metal cutting is uneconomical due to the great effort and material losses involved, or when the section is to be given specific properties that can only be achieved by targeted cold-forming. In our plant EZM Profil Bearbeitung, based in Rohr/Thüringen, sections are manufactured by machining up to 6,200 mm length and a maximum crossing-section of 125 mm, which are needed for for example for linear guides in the machine and plant...

Request for a quote

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

piston Ø 20 mm, stroke 8 mm wedge-shaped cross piston max. 300 bar, as per data sheet B1.730

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

piston Ø 12 mm, stroke 5 mm wedge-shaped cross piston max. 300 bar, as per data sheet B1.730

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

Light Clamps – the clever plastic series: With the plastic tube connectors from the "Light Clamps" series, RK Rose+Krieger has developed a cost-effective and versatile range of tube connectors for the positive connection of tubes in the light load range. This design enables the clamping of the most various tube sections and –diameters. Besides their attractive design and the intelligent system of reducing bushes the clamping elements are characterised especially by their resistance to chemicals. They are particularly appropriate for sensitive applications under laboratory conditions and for industrial applications as, for instance, in the beverage or packing industry.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Besides their own clamp-band designs Freek also manufactures original Rosemount clamp-bands that can be used as "Husky-replacement heaters" (see spare part cross-reference list). For example the two screw clamp band (FB) and the axial clamp band (FE). Freek has all the various industry standards for clamp-band nozzle heaters in Ø19,05 and Ø22,40 in their assortment, too. HotCoil minitubular heaters with clamp band are a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Especially for high-cavity PET plastic injection moulding there are various industry standards of clamp-band nozzle heaters available. Most common are the Axial Clamp-Band Heater and the Two-screw Clamp-Band Heater. Our HotCoil cable heaters with clamp band represent a highly demanded and very flexible clamping system, especially for heating larger nozzles and bushings with high power. The size-variable customizable clamp bands counteract the heating's thermal-related "lifting ambition" during heat-up and thus effectively prevent a possible critical overheating. For an even better protection all HotCoil heating elements can also be provided with an integrated thermocouple. As alternative to our standard clamping mechanism with welded clamping elements a space-saving lug clamping mechanism can be supplied.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK tube connectors – the flexible alternative to welded connections The clampable tube connectors from RK Rose+Krieger are a cost-efficient solution for the positive and ready detachable connection of a diverse variety of systems – without the need for drilling and welding. Depending on the field of application and the expected load, RK Rose+Krieger offers tube connectors made of plastic (Light Clamps), aluminium (Solid Clamps) or stainless steel (Robust Clamps). The Solid Clamps tube connector system also includes the RK monitor mounting for the fixation and ergonomic adjustment of monitors and touch screens used in industrial applications. Say goodbye to welding – that could be the motto of the clampable RK tube connectors The simple assembly technology of the clamping elements eliminates the need for time-consuming and cost-intensive drilling and welding work.

Request for a quote

FRIEDR. FREEK GMBH

Germany

Our Locking System provides a quick, easy and reliable clamping of the heating element on the nozzle to be heated. It facilitates an effective heat transfer, as the inside sheath is pressed to the nozzle with a high level of precision creating an interference fit. Due to the method of construction of the lock, installation is possible in the restrictive space of small cavities. The lock can be operated quickly and efficiently with simple readily available tools.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The Freek heat transfer nozzle heater type especially addresses manufacturers and users who operated their hotrunner nozzles with cast-in heaters in the past and would like to stick to their engineering know-how without paying the high price of this former heater design. The standard material of our patent pending Freek heat transfer alternative is brass, with or without coating, basically with a slit. Characteristics of our HotMicroCoil nozzle heaters sheathed by a reflection tube are easy mounting and variable heat distribution. Because of its direct touch and toleranced fit, the heater allows a very good heat transmission to the nozzle. In all our HotMicroCoils with reflection tube the assembly of a thermocouple is possible and recommended for bigger diameters and power. Also most common nozzle heater solutions are HotMicrocoil heating elements with clamp bands with diverse locking mechanisms.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

Super lightweight aluminum body for direct installation of clamping elements. The PMNM UPC pallet is delivered completely ready fitted to fit the Erowa UPC clamping system with original Erowa elements. Optional with handles and/or link Gripper. is used to clamp small and medium-sized workpieces. It works without an external power supply and is activated manually via a changeover lever.

Request for a quote

WEINLICH GMBH & CO. KG

Germany

- self-supporting bed, - no transfer of torque to the ground - rapid fixation of modules and additional equipment in any axial position without drilling Picture: The modules executing torque on each other consist of electric motors with a high torque transmission. They are secured by strong clamping elements on the test bed. Their axial position is adjustable. The removable protection grid protects only against accidental contact to rotating parts under laboratory conditions. Solid axially movable protection covers are avaiable if parts might detach and fly away.

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Locking Elements consist of an internal and external tapered ring. When axial force is exerted on a set of Locking Elements, radial clamping pressures are generated on the shaft and in the hub bore providing a frictional connection. Units may be stacked up to three elements deep for greater torques. For light to medium duty applications. Characteristics Customized application – by varying the number of Locking Elements, size and quantity of clamping screws, the connection can be adapted to fit most applications concerning surface pressures, materials, hub/shaft dimensions and available mounting space. Transmission of high loads – to increase the transmissible torque and axial forces up to 4 Locking Elements can be used in series. Maximum reliability – no matter whether the connection is subjected to static, pulsating, dynamic or intermittent loads. Simple manufacture – shaft and hub are designed without keyway. Apart from this, relatively large tolerances are admissible. Easy...

Request for a quote

BOLZ PROCESS TECHNOLOGY GMBH

Germany

Pharma Design - Series H 630 - 1600 P The HEINKEL horizontal peeler centrifuges in pharma design are characterized by easy cleaning and inspection avoiding product contamination. Special properties for the customer’s benefit: Swinging open housing for easy inspection Clean room installation possible Hydraulically operated housing locking mechanism by single clamping elements, therefore minimal area for product deposit Fully automatic, validated CIP-process possible Design virtually free of dead spaces, minimized number of screwed connections in the process housing Filtrate outlet at the rear part of the process housing, low dismantling expenses to prepare for the opening of the housing High flexibility at frequent product changes Quick change of the filter element Bearing designed as exchangeable unit

Request for a quote

LUDWIG HUNGER WERKZEUG- UND MASCHINENFABRIK GMBH

Germany

Application With the PVM1 assembly set, worn valve guides can be quickly and easily removed from the cylinder head and new valve guides inserted into the cylinder head. The assembly set is particularly suitable for motorcycle, car and commercial vehicle workshops. Features The air hammer can also be used to drive valve seat inserts out of the cylinder head. For this purpose a Hunger valve seat turning device is used to turn a groove into the valve seat ring. The seat ring is driven out of the cylinder head by means of a clamping head whose expandable clamping elements engage in the groove. Handling Insert the appropriate drift pin into the pneumatic hammer and insert the drift pin into the valve guide. Switch on the compressed air supply with the control lever provided on the pistol grip of the air hammer. The valve guide is driven out of or into the cylinder head by the rapid impact sequence. A soft protective ring placed on the drift pin protects the valve guide from damage.

Request for a quoteResults for

Clamping elements - Import exportNumber of results

43 ProductsCountries

Category

- Machine tools, metal machining - parts and accessories (7)

- Electroheat - machines and equipment (3)

- Metallurgy - machinery and installations (3)

- Industrial tools (2)

- Measurement - Equipment & Instruments (2)

- Temperature sensing devices (2)

- Automation - systems and equipment (1)

- Disks, magnetic (1)

- Elements, electric (1)

- Fastening devices (1)

- Mechanical transmission systems and components (1)

- Paint mixers and grinding machines (1)

- Pipes and tubes, aluminium (1)

- Testing equipment (1)

- Welding work - steels and metal (1)