- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- clamp rings

Results for

Clamp rings - Import export

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

PIERON GMBH

Germany

Dimensions Wire diameter: 0,2 – 8,0 mm Outside diameter: > 120 mm after consultation All wire profiles feasible Material All spring materials and quality steels with lower strengths Coating All commonly coated spring steels In-house phosphating In-house stove-enameling Additional coatings through external services Specialities Clamping rings made of round wire or flat material Clamping rings with a stamp Rings with defined bendings Minimum burr cut-geometry Additional processing available after consultation Customer specific packaging Rapid prototyping

Request for a quote

IGUS® GMBH

Germany

Lead-free - According to (RoHS) 2002/95/EG Standards and Certificates drylin® trapezoidal lead screw nut - cylindrical nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WSRM, JSRM, J350SRM and A180SRM drylin® trapezoidal lead screw nut - cylindrical nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WSLM and JSLM drylin® trapezoidal lead screw nut - flanged nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WFRM, JFRM, J350FRM and A180FRM drylin® trapezoidal lead screw nut - flanged nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WFLM and JFLM drylin® Anti-backlash nuts Trapezoidal leadscrew nuts with reduced bearing clearance. Anti-backlash nuts drylin® split lead screw nuts Split lead screw nuts for easy assembly. drylin® split lead screw nut drylin® leadscrew nut - two start two-start lead screws, double stroke in addition to the usual trapezoidal leadscrew nuts. drylin® two-start leadscrew nut drylin® miniature nuts Screw drives ,iniatur lead screw nuts, small sizes. Miniature nuts small sizes drylin® lead screw nuts with spanner flat Ideal transmission of the torque through form fit. drylin® lead screw nuts with spanner flat drylin® disc drylin® disc – eliminate clearance easily at low cost drylin® disc drylin® - Trapezoidal threaded spindle drylin® - Trapezoidal threaded spindle drylin® - trapezoidal lead screws made from aluminum, coated drylin® - Trapezoidal threaded spindle, Aluminium drylin® - Trapezoidal lead screw spindles with pin drylin® - Trapezoidal threaded spindle with pin drylin® - Trapezoidal lead screw spindles reverse Increased flexibility for format adjustments: counter rotating drylin® lead screws. reverse drylin® Zero backlash screw drives Screw drives with steep thread for quick adjustments. Zero backlash screw drives drylin® steep-threaded nuts For quick adjustments as an alternative to pneumatic or toothed belt. Leadscrews drylin® steep thread DST Lubricant-free steep thread DST higher performance in service life and efficiency Steep thread DST drylin® steep-threaded spindles Lubrication-free threaded spindles with high pitches. Steep-threaded spindles drylin® leadscrew nuts made of SHT linear modules Threaded nuts made of SHT linear modules drylin® leadscrew nuts made of SHT linear modules drylin® leadscrew nuts made of SLW linear modules Threaded nuts made of SLW linear modules drylin® leadscrew nuts made of SLW linear modules drylin® leadscrewsstorage Anodized aluminum bearing blocks of iglidur® L250. Design your own linear table. Leadscrewsstorage Floating bearing block for lead screws with ball bearing Useful extension to the drylin® construction kit. Floating bearing block for lead screws with ball bearing drylin® lead screw nut retainer Conveniently use srews to standard lead screw nuts with nut retainers drylin® lead screw nut retainer drylin® spherical trapezoidal lead screw nut To compensate for angular errors in screwed on plates. Spherical trapezoidal lead screw nut drylin® spherical lead screw nut with flange housing spherical trapezoidal lead screw nut, which permits continuous angle adjustments. drylin® leadscre nut with flange housing drylin® spherical lead screw nut with pillow block bearing Spherical lead screw nut with pillow block bearing continuous angle adjustments. drylin® lead screw nut with pillow block bearings drylin® quick-release nut – Fast Forward Fast forward mechanism: A combination of accurate positioning and quick manual adjustment with trapezoidal lead screw nuts. Quick release mechanism drylin® clamping rings drylin® clamping rings - flexible even down to the finest of details, made of coated aluminum. drylin® clamping rings drylin® trapezoidal lead screw nut - cylindrical nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WSRM, JSRM, J350SRM and A180SRM drylin® trapezoidal lead screw nut - cylindrical nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WSLM and JSLM drylin® trapezoidal lead screw nut - flanged nuts with right-hand thread Trapezoidal lead screw nuts made from lubricant-free iglidur® W300, J, J350 and A180. drylin® - trapezoidal leadscrew nuts - WFRM, JFRM, J350FRM and A180FRM drylin® trapezoidal lead screw nut - flanged nuts with left-hand thread Trapezoidal leadscrew nuts made from lubrication-free iglidur® W300 and iglidur® J. drylin® - trapezoidal leadscrew nuts - WFLM and JFLM drylin® Anti-backlash nuts Trapezoidal leadscrew nuts with reduced bearing clearance. Anti-backlash nuts drylin® split lead screw nuts Split lead screw nuts for easy assembly. drylin® split lead screw nut drylin® leadscrew nut - two start two-start lead screws, double stroke in addition to the usual trapezoidal leadscrew nuts. drylin® two-start leadscrew nut drylin® miniature nuts Screw drives ,iniatur lead screw nuts, small sizes. Miniature nuts small sizes drylin® lead screw nuts with spanner flat Ideal transmission of the torque through form fit. drylin® lead screw nuts with spanner flat drylin® disc drylin® disc – eliminate clearance easily at low cost drylin® disc drylin® - Trapezoidal threaded spindle drylin® - Trapezoidal threaded spindle drylin® - trapezoidal lead screws made from aluminum, coated drylin® - Trapezoidal threaded spindle, Aluminium drylin® - Trapezoidal lead screw spindles with pin drylin® - Trapezoidal threaded spindle with pin drylin® - Trapezoidal lead screw spindles reverse Increased flexibility for format adjustments: counter rotating drylin® lead screws. reverse drylin® Zero backlash screw drives Screw drives with steep thread for quick adjustments. Zero backlash screw drives drylin® steep-threaded nuts For quick adjustments as an alternative to pneumatic or toothed belt. Leadscrews drylin® steep thread DST Lubricant-free steep thread DST higher performance in service life and efficiency Steep thread DST drylin® steep-threaded spindles Lubrication-free threaded spindles with high pitches. Steep-threaded spindles drylin® leadscrew nuts made of SHT linear modules Threaded nuts made of SHT linear modules drylin® leadscrew nuts made of SHT linear modules drylin® leadscrew nuts made of SLW linear modules Threaded nuts made of SLW linear modules drylin® leadscrew nuts made of SLW linear modules drylin® leadscrewsstorage Anodized aluminum bearing blocks of iglidur® L250. Design your own linear table. Leadscrewsstorage Floating bearing block for lead screws with ball bearing Useful extension to the drylin® construction kit. Floating bearing block for lead screws with ball bearing drylin® lead screw nut retainer Conveniently use srews to standard lead screw nuts with nut retainers drylin® lead screw nut retainer drylin® spherical trapezoidal lead screw nut To compensate for angular errors in screwed on plates. Spherical trapezoidal lead screw nut drylin® spherical lead screw nut with flange housing spherical trapezoidal lead screw nut, which permits continuous angle adjustments. drylin® leadscre nut with flange housing drylin® spherical lead screw nut with pillow block bearing Spherical lead screw nut with pillow block bearing continuous angle adjustments. drylin® lead screw nut with pillow block bearings drylin® quick-release nut – Fast Forward Fast forward mechanism: A combination of accurate positioning and quick manual adjustment with trapezoidal lead screw nuts. Quick release mechanism drylin® clamping rings drylin® clamping rings - flexible even down to the finest of details, made of coated aluminum. drylin® clamping rings Lead-free - According to (RoHS) 2002/95/EG Standards and Certificates

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Short description: For clamp ring binding

Request for a quote

GRÜNING & LOSKE GMBH

Germany

Type MK, TW crown ring with female thread, clamping ring and lever

Request for a quote

SIKO GMBH

Germany

The AP05 position indicator guides the user intuitively to the correct machine setting in the case of product or format change. The optimized backlit display indicates target values and actual values straight to the point. Two LEDs show the machine operator precisely the direction whereto the adjustment is to be performed.The AP05 helps avoid wrong machine settings and enhances process safety of flexible production machines. Electronic position indicator with bus interface. Backlit two-row LCD. Display of target and actual value displays with integrated alignment. User guidance through status LEDs. Hollow shaft with Ø 20 mm and clamping ring made of stainless steel. Enhanced shock resistance owing to protective display glass. Integrated RS485 interface, CAN bus as an option. Robust sensor technology unit thanks to magnetic scanning. Mechanically compatible with the AP04 and DA04 position indicators. IP53 type of protection, IP65 as an option.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We produce for the martitim needs: railings, tubes, handrails, fittings, stairs, floors, rope tensioner, shroud spanner, skirting boards, aeration, lifting rings, clamps, rod holders, anchors, big-sized parts, angles, tees, safeguarding, thimbles, pressing sleeves and much more... Take profit also from our 3D-printign service for plastic & silicon parts. We realize your individual demans!

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives. All CR-M series mixers can be supplied as follows:

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

LRK-C mit Antrieb LRK-A Electrical tote tank mixers for stainless steel IBCs The LRK-C series tote tank mixer and their drive units LRK-A are a special solution designed for operation on stainless steel containers with filling openings of at least 400 mm and mixing volumes from 400 l up to 1,500 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives. The mixing unit that remains in the container is connected to the drive unit with a bayonet coupling and a clutch. The drive is dismountable so that one drive unit can be used for several mixer units interchangeable. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The agitator shafts are borne in a bearing housing, which is welded into the container lid on the product side. The impellers are designed to fit through the filling opening DN 400 when being inserted. If required, the electric tote...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CRP-M - Pneumatic tote tank mixer for stainless IBCs The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

CR-M - Electric tote tank mixer for stainless steel IBCs The tote tank mixers CR-M are designed for operation on stainless steel containers with filling openings of DN 400 mm and mixing volumes from 400 l up to 1,500 l. Depending on the viscosity of the mixing material, CR-Ms with fast running or gear reduced drives are available. The agitator shafts are connected to the drive shafts with sleeve couplings or borne within the gear’s hollow shaft (worm gear). The agitator shafts are balanced for concentric run after assembly. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening DN 400 when being inserted. The electric container mixers are delivered with on-/off-switches with low-voltage breaker. The electric container mixers can also be supplied with frequency converter drives. All CR-M...

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

The CRP-M tote tank mixers are featured with a pneumatic drive and were designed for the application in stainless steel tanks with filling openings of at least 400 mm and mixing volumes of 400 l to 1,500 l. The fast running pneumatic agitators are equipped with bearing and coupling housings. By means of the maintenance unit, pressurized air is enriched with oil for the vane drive. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The manway lid is supplied by the container manufacturer or by the customer. The impellers are designed to fit through the filling opening of at least 400 mm when being inserted. All CRP-M series can be supplied as follows: Lid Muffler Explosion-protection design

Request for a quote

GEPPERT RÜHRTECHNIK GMBH

Germany

Electrical tote tank mixers for stainless steel IBCs The LRK-C series tote tank mixer and their drive units LRK-A are a special solution designed for operation on stainless steel containers with filling openings of at least 400 mm and mixing volumes from 400 l up to 1,500 l. The customer may choose between various viscosity-related basic versions of fast-running and slow-running mixers with electric drives. The mixing unit that remains in the container is connected to the drive unit with a bayonet coupling and a clutch. The drive is dismountable so that one drive unit can be used for several mixer units interchangeable. The mixer is mounted on the container’s manway lid, which is clamped with butterfly screws or a clamp ring. The agitator shafts are borne in a bearing housing, which is welded into the container lid on the product side. The impellers are designed to fit through the filling opening DN 400 when being inserted.

Request for a quote

FLAIG MAGNETSYSTEME GMBH & CO.KG

Germany

FX-C lifting magnets have a round, multipole clamping surface, designed for lifting rings, sleeves, bearing housings, flange plates and similar workpieces.The load specification is valid for full-surface mounting on workpieces which cover D inside to D outside (see table Dimensions), for workpieces with a smaller mounting surface an approximate maximum workpiece weight of 3.5 kg per cm² clamping surface can be calculated. For serial workpieces, a documented test should confirm the safety factor 3.

Request for a quote

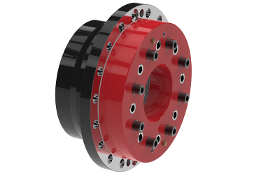

RINGFEDER POWER TRANSMISSION GMBH

Germany

Two piece design similar to 7006, but extended with lower shaft and hub pressures. 7007 ECOLOC Is a modification of 7004 ECOLOC with all its positive features, but here - same as 7006 ECOLOC - the axial displacement during mounting is averted. Explanations L = Overall width L 1 = Overall width (without screws) L 4 = Installation length up to colar L 3 = Clamping length d = Inner ring diameter D = Outer diameter D 1 = Collar outer diameter

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Three piece self-centering design for heavy duty torques. 7005 ECOLOC Three piece, self-centering, slitted locking assemblies for highest bending moments and torques. During assembly a minor axial displacement of the hub occurs. The front and rear thrust rings are separately released through release threads. Explanations L = Overall width L 1 = Overall width (without screws) L 3 = Clamping length d = Inner ring diameter D = Outer diameter

Request for a quote

RINGFEDER POWER TRANSMISSION GMBH

Germany

Extended version of the 7003 allowing for use with smaller hub diameters due to the reduced shaft and hub pressures. 7004 ECOLOC Is the extended design of series 7003 ECOLOC. Here, due to the low pressure the hub can be designed very cost-effective (small outer diameter). Explanations L = Overall width L 1 = Overall width (without screws) L 3 = Clamping length d = Inner ring diameter D = Outer diameter

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PTEC PRESSURE TECHNOLOGY GMBH

Germany

Service pressure: 0-26 Mpa Service temperature: -40°C up to 85°C Reliable in filling and operation direction Small construction Corrosion-resistant All seals are suitable for CNG Certification: ECE R 110 The valve is equivalent of heavy metal regulation Burst pressure: > 100 Mpa, 20° Orfice diameter: 4, 6mm Connection: 6, 8mm tube or 3/8" Tightness: 1x10-5mbar l/s, 20°C, 100% He

Request for a quote

TAS SCHÄFER GMBH

Germany

The clamping tool is placed onto the front of one coupling half and is used to clamp the pressure ring of the coupling. After fixing the coupling half, the tool is removed and can be used for further couplings of the same nominal size. The clamping tool is placed onto the front of one coupling half and is used to clamp the pressure ring of the coupling. After fixing the coupling half, the tool is removed and can be used for further couplings of the same nominal size.

Request for a quote

H. TIMM ELEKTRONIK GMBH

Germany

4 m Neoprene Grounding Cable with 2-pole Grounding Clamp on one and a Ring Terminal on the other side. Simple bonding connection suitable for unsupervised grounding. Purchase of equipment for German customers only. Please contact your local sales partner . Description Neoprene Grounding Cable 2 x 1.5 mm², 4 m long, ready for connection, with grounding clamp type EZ-1 2-pole in stainless-steel with rubber insulating sheath for simple bonding connection. The grounding clamp contacts with the upper and lower bracket, thus marked 2-pole. The grounding line is laid on one ring terminal at the other cable end. Grounding clamp with separate ATEX-Certificate for the use in hazardous areas of zones 1 and 2. The other side will be assembled with a ring terminal end M8 (both cable wires combined) and 10 cm long transparent PVC hose (10 x 13 mm) for mounting a strain-relief.

Request for a quote

EM-TECHNIK GMBH

Germany

The flexible tube is pushed onto the integrated connecting sleeve of the 1A flexible tube con-nector. By tightening the knurled nut, the clamping ring presses against the flexible tube and fixes it in place. The connecting sleeve for the flexible tube is nearly cylindrical. Its dimensions are calculated to prevent tube strain over 6%, even with poor tolerances. The tension produced by the low tube strain is sufficient by itself to guarantee a tight flexible tube connection up to 6 bar. The clamping ring and knurled nut secure the connection against longitudinal forces which could otherwise pull the flexible tube off the connecting sleeve. The clamping ring is designed to secure the flexible tube in place by intercepting any shear or tor-sional stresses. This allows for usage up to 10 bar*. Thanks to its elasticity, the clamping ring can be used several times in the same connector.

Request for a quote

EM-TECHNIK GMBH

Germany

This connector is specially designed for mesh-reinforced flexible tubes. As all of the Generation+ connectors, it consists of only two parts: the connector body and the pressure screw. The clamping ring is incorporated into the pressure screw. An extra clamping ring is not required. The thread and connecting sleeve are integrated inside in the connector body. The advantage: they cannot be damaged and are protected against external effects.

Request for a quote

EM-TECHNIK GMBH

Germany

The 1+ connector consists of just two parts, the connector body and the pressure screw. The clamping ring is incorporated into the pressure screw. The thread and connecting sleeve are integrated inside in the connector body. They cannot be damaged and are thus protected against external effects. Further advantages: The connector is completely leak-proof when it is "hand-tight" and no tools are required. This significantly reduces assembly times. The pressure screw can also be tightened with a fork wrench so there is no gap between the connection and the connector body.

Request for a quote

EM-TECHNIK GMBH

Germany

The special design of the 1W+ makes it possible to slide the corrugated flexible tube directly onto the slightly conical connecting sleeve inside the connector body. Then when the pressure screw is threaded in, the corrugated flexible tube is fixed in place on the connecting sleeve. No extra clamping ring is necessary because it is integrated into the pressure screw. That means the connector consists of only two parts, which makes handling considerably easier.

Request for a quote

SERVOLIFT GMBH

Germany

Working with and handling drums is done all the time in the pharmaceutical, chemical and food industries. That is why efficient drum handling is a must, and needed in order to optimally structure operational processes. Our products help you with this and offer you a variety of opportunities. Efficient drum handling for drums of any diameter and material Technical description Stainless steel or cGMP-compliant designs High flexibility, such as for drums with any dimensions and of any design No load limitation Tilting function: lengthwise or cross-wise to the column Stationary or mobile designs Floor/ceiling-mounted, free-standing or ceiling-positioned designs Electro-hydraulical or electro-mechanical solutions Extensive series of control designs, from simple direct manual lever controls up to PLC-controlled sequences Various take-up and clamping systems such as a manual clamping ring, motor-driven clamp system, squeeze funnel clamp, fork shaped spears, special designs depending...

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The knives of knife-ring akers have to be sharpened and re-set at regular intervals. This can be a very timeconsuming and personnel-intensive job. The quality and precision of these tasks depend strongly on the accuracy and dedication of the individual worker. With the sharpening and setting robot PZSE the knives can be sharpened and set automatically. Features, Function safety housing fully automatic process ow transport to and clamping of the knife ring to the carrier disc determining the wear of all parts automatic readjustment of all wear shoes and knives sharpening of all knives in a wet grinding process cleaning torque control of clamping bolts detection of possible damage to the threads Advantages automatic sharpening and setting process setting of the knives with high accuracy electronic control of tightening torque of the knife xing bolts automatic monitoring of the thread quality of the xing bolts preventative maintenance program thanks to PLC-controlled integrated

Request for a quote

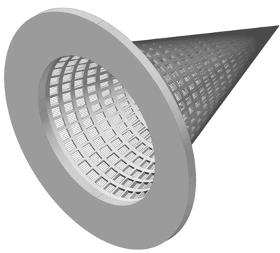

THIELMANN ENERGIETECHNIK GMBH

Germany

CHARACTERISTICS For clamp mounting into the pipeline Efficient protection of dirt-sensitive system components during commissioning Low differential pressure Easy installation and replacement Material Certificates DIN EN 10204/3.1 for Clamp Collar OPTIONS For DIN and ASME flange connections Design for low temperature down to -50 ° C Design pressure up to 100 bar Stainless steel construction Reverse flow direction GENERAL The starting screen VAS is used for commissioning and starting a system in order to clean gas from coarse soiling such as welding bead, scale, grease, etc. After starting, the starting screen can be removed from the pipeline. The design is carried out as a welding design. FUNCTION The starting screen VAS consists of a supporting basket made of perforated sheet metal with a welded clamping ring. These are galvanized after assembly. On the outside of the support basket a stainless steel wire mesh is welded.

Request for a quote

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

The knives of knife-ring flakers have to be sharpened and re-set at regular intervals. This can be a very time-consuming and personnel-intensive job. The quality and precision of these tasks depend strongly on the accuracy and dedication of the individual worker. With the sharpening and setting robot PZSE the knives can be sharpened and set automatically. Features, Function Safety housing Fully automatic process flow Transport to and clamping of the knife ring to the carrier disc Determining the wear of all parts Automatic readjustment of all wear shoes and knives Sharpening of all knives in a wet grinding process Cleaning Torque control of clamping bolts Detection of possible damage to the threads Advantages Automatic sharpening and setting process Setting of the knives with high accuracy Electronic control of tightening torque of the knife fixing bolts Automatic monitoring of the thread quality of the fixing bolts Preventative maintenance program thanks to...

Request for a quote

SONIKKS® ULTRASONICS TECHNOLOGY GMBH

Germany

In ultrasonic systems, the booster functions as a transmission tool to change the amplitude provided by the converter. It then forwards it to the sonotrode of the oscillating system. Depending on the design and installation direction, the amplitude can be reduced or increased by the booster. The booster is also suitable to embed the vibrating system into a machine if a clamping or tension ring is attached to it. soniKKs boosters stabilize the vibration behavior and ensure lossfree transmission through completely flat coupling surfaces. We usually manufacture our boosters from titanium. This material maintains its positive properties even at high temperatures. It has an exceptionally high corrosion resistance and belongs to the light metals. We are happy to match our boosters to your specific needs. Your Advantages “Made in Germany” Usually made of titanium Lossfree transmission due to optimally processed coupling surfaces Suitable for the food and pharmaceutical industry

Request for a quoteResults for

Clamp rings - Import exportNumber of results

43 ProductsCountries

Category

- Plumbing, domestic (7)

- Plastics - industrial machinery and equipment (4)

- Chemical and pharmaceutical industry - machinery and equipment (3)

- Clutches (2)

- Forming - steels and metals (1)

- Magnets (1)

- Sensors (1)

- Ship equipment (1)

- Springs (1)

- Stamping - steels and metals (1)

- Wood veneer - machinery and equipment (1)