- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- buffers

Results for

Buffers - Import export

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

Gronemeyer Heliflex storage systems store general cargo that is up to 400 mm wide and 160 mm high. The products are transported on a plastic Heliflex chain. The chain is wound around two rotating towers in a spiral. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle. Technical data: —Chain width: up to 400 mm —Usable chain length: up to 1,000 m —Independent electrical control system Optional equipment: —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer FIFO spiral buffer stores general cargo and bulk goods. The products are transported on a plastic mat conveyor chain. The chain is wound around one or two rotating towers in a spiral. The design of the machine permits storing unpackaged food. The machine works according to the First In-First Out principle. Technical data: —Chain width: up to 1,400 mm —Usable chain length: up to 1,000 m —Independent electrical control system Optional equipment —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The preferred field of application for the (gas) hydraulic industrial buffer (COMPENSER®) of the S-series is in the medium to heavy engineering industry sector. As a heavy duty shock absorber it is used in large crane systems (e.g. harbour crane, shipyard crane or container crane), metallurgical plants, rolling mills, loading systems or as end stop integrated in a rail buffer stop. Design & Function: The gas-filled inner tube 2 enters the outer tube 9. The damping medium flows from the pressure chamber 6 through the throttle orifices 8 of the metering tube 7 into the volume balance chamber 5. The separating piston 4 simultaneously moves in the direction of the impact cap 1 and compresses the nitrogen gas filling. In the gas space 3, the energy is stored which is required for the reset of the inner tube. When the inner tube 2 returns to the initial position, the separating piston 4 moves in the opposite direction and presses the damping medium back into the pressure chamber 6.

Request for a quote

DR. PAUL LOHMANN GMBH & CO. KGAA

Germany

Dr. Paul Lohmann® offers Triammonium Citrate as crystalline powder in food and chem. pure grade. For food applications, it is used as acid regulator. For industrial applications, it is used as a pH buffer, catalyst and chelating agent. It also allows to increase the current density in electrochemical processes. CAS 3458-72-8 EINECS 222-394-5 Dr. Paul Lohmann® carries out product and application development in close cooperation with customers. This includes the adaptation of chemical and physical parameters such as bulk density, wettability, particle size, purity or pH-value.

Request for a quote

DR. PAUL LOHMANN GMBH & CO. KGAA

Germany

Dr. Paul Lohmann® offers Sodium Succinate 6-hydrate as powder and solution in food/pharma and chem. pure grade. For biopharmaceutical applications, it is used as a pH buffer in cell culture media. For food applications, it is used as a flavoring agent. For industrial applications, it is used as a stabilizer for electroplating baths, as a nucleating polymer additive and as a crystallization modifier in gypsum production. CAS 6106-21-4 EINECS 205-778-7 Dr. Paul Lohmann® carries out product and application development in close cooperation with customers. This includes the adaptation of chemical and physical parameters such as bulk density, wettability, particle size, purity or pH-value.

Request for a quote

HO-MA GMBH

Germany

Increased output for further processing Tool-free format change Quick adjustment to product formats Selectable direction of rotation

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

The LIPP® Large Thermal Storage Tank is a customized solution to effectively store excessive heat from biogas plants, biomass heating plants, solar plants or other heat sources. The carbon steel tanks are fabricated on site with the patented automated LIPP® Welding Technology. The horizontal welding process enables the infinitely variable production of tanks up to 6,000 m³ volume with horizontal welding only. The largevolume, above ground storage tanks are fitted with all necessary safety and operation equipment. Additional, individual components according to client’s specification can be considered. The roof and wall insulation is individually adapted to local conditions. The LIPP® Thermal Storage Tanks operate at atmospheric pressure, at a temperature of up to 95° C and are suitable for use with heating water. Speciality No additional nitrogen system necessary.

Request for a quote

SPANSET SECUTEX GMBH

Germany

The light and mobile coil mat was designed for the storage of coils. It is convenient to use. Thus, makeshift storage can be set up rapidly and flexibly. Alternatively, existing storage can be expanded should bottlenecks arise.

Request for a quote

SCHWEIZER GMBH & CO. KG

Germany

Universal stainless steel exhaust system accessories. Everything you need to build your own exhaust system. Holder or lambda probe thread up to the exhaust spring, which are used for slip on exhaust systems.

Request for a quote

DR. PAUL LOHMANN GMBH & CO. KGAA

Germany

Dr. Paul Lohmann® offers Tripotassium Citrate as powder, free flowing powder, fine powder, crystals in food/pharma/chem. pure grade as well as for food supplements. For pharmaceutical applications, it is used for the treatment of hypokalemia. For food applications, it is used as acid regulator. For industrial applications, it is used as pH buffer, complexer and conductivity enhancer for electrochemical processes. CAS 866-84-2 \ 6100-05-6 EINECS 212-755-5 Dr. Paul Lohmann® carries out product and application development in close cooperation with customers. This includes the adaptation of chemical and physical parameters such as bulk density, wettability, particle size, purity or pH-value.

Request for a quote

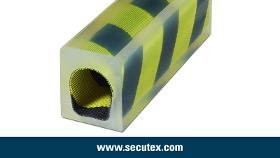

SPANSET SECUTEX GMBH

Germany

The secutex buffer pad with hollow profiles and fabric insert act as an effective buffer. The hollow cavity absorbs collision energy and protects the load from damage. The secutex buffer pad comes with a standard yellow and black fabric insert.

Request for a quote

HO-MA GMBH

Germany

High volume Single track conveyor belt

Request for a quote

BRUGGER GMBH MAGNETSYSTEME

Germany

Alternative to the standard we also offer individual solutions: » other colours possible

Request for a quote

SIKO GMBH

Germany

Display accuracy max. 10 μm. Repeat accuracy max. ±0.01 mm. Lowest-power LCD. Reading distance ≤2 mm. Incremental measurement and reset function. Direct reference/offset value input. Hard-wired sensor.

Request for a quote

GERBU BIOTECHNIK GMBH

Germany

Storing temperature: 10-25°C Shipping condition: ambient.

Request for a quote

GERBU BIOTECHNIK GMBH

Germany

Shipping condition: ambient.

Request for a quote

SÜTHER & SCHÖN GMBH

Germany

Washers for spring buffers * spring buffer with collar

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RINGFEDER POWER TRANSMISSION GMBH

Germany

RINGFEDER Friction Springs can also be supplied in customized buffer versions. Features of RINGFEDER ® Friction Springs RINGFEDER ® Friction Springs are employed in the engineering sector when high kinetic energies must be absorbed or when springs of relatively compact dimensions are required for high forces. Friction springs RINGFEDER ® have multitude features in opposite to other damping systems: High spring work combined with low weight and volume: As RINGFEDER ® Friction Springs completely utilise the material of which they are made only a minimum of dimensions and weight are required. The decisive parameter here is therefore the spring work. High Damping Potential: The damping of Friction Springs RINGFEDER ® is standard with 66% wherewith the energy will be soon absorbed and resonances complete disabled. Variations are possible with different greases. Overload-safe in blocked position:RINGFEDER ® Friction Spring are generally designed to “block”, so it is therefore ensured...

Request for a quote

SEALS-SHOP.COM - TRELLEBORG SEALING SOLUTIONS

Germany

In heavy duty applications, leak free performance and high service life cannot be assured by a single sealing element; therefore, specially developed ”system seals” are arranged in series, building a ”tandem configuration”. Each sealing element in a system has its specific function and their interaction needs to be secured to get a redundant sealing system. The primary seal in Zurcon® material has an excellent wear and extrusion resistance under extreme working conditions. It allows a fine lubrication film passing this first barrier, ensuring the necessary lubrication of the secondary sealing element for long service life. The ”tandem arrangement” requires an outstanding back-pumping ability of the primary seal and the secondary seal, if a double acting scraper is installed.

Request for a quote

TAS SCHÄFER GMBH

Germany

The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column is shortened. This has the effect that the outer rings stretch and the inner rings reduce in diameter. As a result of the friction arising on the conical surfaces, the introduced energy is absorbed and converted into heat which is to be removed. Resonance effects are suppressed completely. The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column...

Request for a quote

TAS SCHÄFER GMBH

Germany

The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column is shortened. This has the effect that the outer rings stretch and the inner rings reduce in diameter. As a result of the friction arising on the conical surfaces, the introduced energy is absorbed and converted into heat which is to be removed. Resonance effects are suppressed completely. The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column...

Request for a quote

TAS SCHÄFER GMBH

Germany

The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column is shortened. This has the effect that the outer rings stretch and the inner rings reduce in diameter. As a result of the friction arising on the conical surfaces, the introduced energy is absorbed and converted into heat which is to be removed. Resonance effects are suppressed completely. The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column...

Request for a quote

TAS SCHÄFER GMBH

Germany

The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column is shortened. This has the effect that the outer rings stretch and the inner rings reduce in diameter. As a result of the friction arising on the conical surfaces, the introduced energy is absorbed and converted into heat which is to be removed. Resonance effects are suppressed completely. The primary function of a friction spring is the damping / absorbing of introduced energy. A friction spring consists of closed outer and inner rings which intermesh with their conical surfaces. As a result of the energy introduced axially, the outer and inner rings on the conical surfaces are shifted apart from each other so that the spring column...

Request for a quote

GRONEMEYER MASCHINENFABRIK GMBH & CO.

Germany

The Gronemeyer accumulation table can store large quantities of glasses, bottles or tins. The products are pushed to the accumulation table if there is backlog. The products are later re-fed into production by operating the system in reverse. The machine works according to the First In-Last Out principle. In case of malfunction, the electrical control system activates the accumulation table based on sensor messages. After the malfunction ends, the stored products are automatically fed into the line. Technical data: —Chain width: up to 3,000 mm —Usable chain length: up to 20 m —Independent electrical control system Optional equipment: —Complete machine cover made of Makrolon with maintenance doors —Loading and unloading belts —Insulated module with air conditioning technology for perishable goods

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

This design by LEBENDämpfungstechnik GmbH acts as a hydraulic shock absorber in both, pulling and pushing direction. The energy dissipation of this kind of industrial shock absorber is performed in two ways Working principle As a purely hydraulic variant (TwinStroke®) – in push (compression) direction hydraulically reversible by means of damping medium – in pull (tension) direction hydraulically reversible by means of damping medium The TwinStroke® dampens push and pull forces without an additional functional element. A piston system transmits the push and pull forces gashydraulically to different gas and oil chambers. In this way, any load can be absorbed immediately without idle stroke, socalled “slack”, and with minimal wear. The TwinStroke® can absorb changing loads very well. The smaller size and lower weight is advantageous, as only one element is needed to absorb compression and tension forces.

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The COMPENSER® of the DC-series is an ideal hydraulic shock reducing element especially for the application field of storage technology (storage and retrieval machines). As a doubleacting buffer, this industrial shock absorber can be used in a spacesaving manner due to its design and can be actuated alternately from both sides. The constructive design and function corresponds to the C-Type. Furthermore, due to its low reset force, it can easily be pressed in at creep speed during operation. As optional equipment PU caps as inserts for the impact cap for the reduction of impact noise and a monitoring of the piston rod‘s position (by either magnetic or inductive sensors) are available. If only a slight increase of reset force of the piston rod over the entire stroke is desired, an additional external accumulator can be fitted to the cylinder to increase the gas volume of the gas spring. Hence the reset force decreases in retracted state.

Request for a quote

FTK FÖRDERBAND TECHNIK KILIAN GMBH

Germany

Buffer rings absorb the falling energy of the conveyed goods and thus protect the belt from damage. The buffer rings (rubber rings) from FTK Förderband Technik Kilian GmbH are permanently attached to the conveyor roller and are characterized by their wear resistant quality. In addition to the tried and tested standard, we also manufacture rings in special quality, e.g. B. white food quality, oil and fat resistant or for the extreme temperature range ( 40 ° C to 180 ° C).

Request for a quote

LEBEN-DÄMPFUNGSTECHNIK GMBH

Germany

The hydraulic industrial shock absorber of the C-series (COMPENSER®) is the ideal hydraulic buffer for storage and retrieval machines or smaller conveyor systems, crane systems, test stands etc. in light to medium mechanical engineering. Due to its short design, this hydraulic buffer (COMPENSER®) can be used in a spacesaving manner as limitation of the end position (as emergency end stop) in industrial applications. In addition, the low reset force allow operational pushin cycles at creep speed. Design & Function: The piston rod 2 enters the metering tube 3. The damping medium flows from the pressure chamber 6 through the throttle orifices 4 of the metering tube 3 into the volume balance chamber 5. The nitrogen gas between the outer tube 7 and the metering tube 3 is compressed and stores the energy required for the reset of the piston rod. When the piston rod 2 returns to the initial position, the damping medium flows back into the pressure chamber 6.

Request for a quoteResults for

Buffers - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Conveyor belts (3)

- Cylinders, hydraulic (3)

- Conveyor systems (2)

- Chemicals - Basic Products & Derivatives (2)

- Chemistry, inorganic - raw materials and derivatives (2)

- Cutting - machine tools (2)

- Food Industry - Machines & Equipment (2)

- Pumps, hydraulic (2)

- Storage tanks (1)

- Additives, food (1)

- Aluminium sheets and bands (1)

- Rubber products (1)

- Seals (1)

- Sensors (1)

- Sheet metal and strips, tinplate (1)

- Spiral springs (1)

- Tanks, metal (1)