- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- vibrators

Results for

Vibrators - Import export

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— No stirring agitator or other rotating parts for ingredient flow without degradation — Vibration amplitude feedback ensuring linear conveyance characteristics over the entire feed rate range Power range 10 - 450 dm³/h 20 - 1000 dm³/h 300 - 3000 dm³/h 650 - 6500 dm³/h

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Depending on type, multi-directional dampers can be loaded in every axis. In our standard vibration dampers of the GDZ series two all-metal cushions are installed. Depending on the assembly, these cushions are load with pressure or tension. Vibration dampers of the series 7 have another cushion obstructed which allows them to absorb load in horizontal direction additionally. Because of this, GDZ dampers are perfectly suitable for applications in the fields of plant engineering and rail vehicle construction. Our product range includes three different types of these multi-directional dampers: GDZ series 1 for a fixation with bolts for pressure and tension load GDZ series 5 for a welding fixation for pressure and tension load GDZ series 7 for a fixation with bolts for pressure, tension and horizontal load

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Damping cushions made of stainless steel are knitted and pressed in a special process. Depending on size, density and design it can be loaded in a range between 5 and 20.000 kg. It can be pressed in cylindrical or rectangular shape. Versions with bunches and steps are available. Standard materials are 1.4301 and 1.4404. Additional materials and special designs are on demand. RG+ offers the following damping cushions as standard elements: GKK as a vibration damper in cylindrical form GKR as a vibration damper in rectangular form GKB as a vibration damper with a bunch

Request for a quote

IGUS® GMBH

Germany

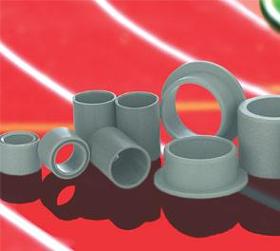

iglidur® B: Highest vibration dampening Vibration dampening is the salient feature of the iglidur® B bearings, which are also well-suited for edge loads at low forces. iglidur® B is available as cylindrical bearings and plain bearings with flange. Sound isolation Extremely high elasticity Sealing function possible

Request for a quote

IGUS® GMBH

Germany

iglidur® M250: Thick and Robust iglidur® M250 bearings are vibration dampening, rugged and wear resistant. In applications with low speeds, they balance edge loads very well and help to minimize noise. iglidur® M250 is available as cylindrical bearings, plain bearings with flange and thrust washers. Excellent vibration dampening Insensitive to misalignment High impact strength For greater wall thicknesses according to DIN 1850 Dirt can accumulate

Request for a quote

GHM MESSTECHNIK GMBH

Germany

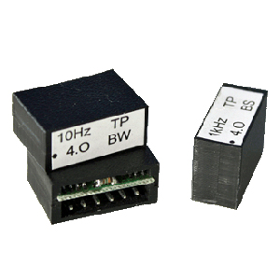

Filter module Frequencies from 10 Hz..10 kHz Butterworth/Bessel characteristics Low ripple < 2 mVpp

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

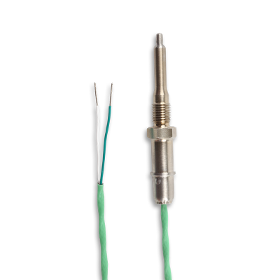

This plug-in sheathing thermocouple is recommended for measuring the temperature in the exhaust gas flow. It is genuinely multipurpose, mounting with the cap nut means the thermocouple does not need to be rotated, which simplifies installation and fast replacement. In addition, it has “motor sports genes” such as vibration resistance, fast response time and high temperature resistance. The benefits: Vibration-proof Fast response time High temperature resistance (up to 1,200 °C) Various installation lengths can be supplied With cap nut Sheathed thermocouple NiCr-Ni, Type “K”, Class 1

Request for a quote

BURRE HYDRAULIK GMBH

Germany

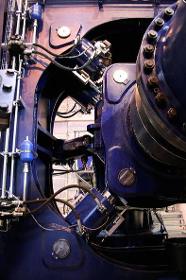

gear box test rig for renewable energies

Request for a quote

THERMA THERMOFÜHLER GMBH

Germany

This sensor for measuring exhaust gases was developed together with a Formula 1 team. The goal was to achieve the greatest possible reliability during the race. The sensor was designed so that it can withstand a maximum of vibrations and extreme temperatures while being made in a highly compact construction at the same time. The special feature is the connection lead. It is not made from the usual mineral-insulated stainless steel sheathed line, which is too rigid and which tends to vibration fractures. Instead, the line is made of stranded conductors with PTFE insulation and an additional heat shield so it can be easily and flexibly adapted to the environment. The sensor is being used with exceeding success by professional teams in long distance races, American race series and the domestic DTM. The benefits: Highly vibration-proof Very robust High temperature resistance (up to 1,200 °C) Individual plug assembly possible Can be individually adapted

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

Vibration damper of the series GMF are especially designed for machine tools. The elements GMF-( )-4 are made to mount small presses or cutters. Depending on the size of the elements they have a load range between 250 and 10.000 kg. Vibration damper of the series GST have an own levelling integrated, so they can compensate small unevenness on the floor. Our product range includes three different types of machine feet: GMF-( ) as a vibration damper especially for machine tools GMF-( )-4 as a vibration damper especially for small presses GST-( ) as a vibration damper with integrated levelling

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

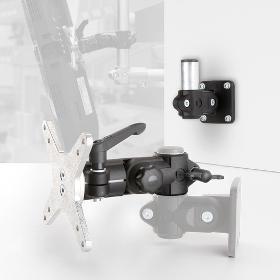

Monitor swivel arms for ergonomic workstation design The monitor mountings from RK Rose+Krieger allow for an optimal view of the monitor or a control panel. The range of action can be increased even further by using a swivel arm. This may be useful for carrying out set-up work on machinery for example, or if the monitor is having a disruptive impact on the working environment. There is also the option of expanding the support arm with two support tubes (twin version) to include a sturdy keyboard tray. The modular design of the RK swivel arm/support arm system allows for varied combination options and helps to adapt workstations to the most ergonomic arrangement.

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

RK monitor mounting – high-strength, flexible and individually adaptable VESA or universal mount for connecting monitors, displays or control panels. Monitors, touch screens, displays and control panels are used every day, and not just in the office. Industrial machines and systems are programmed or performance data displayed on modern touch screens or control panels. In utility vehicles, camera monitoring systems facilitate resetting and navigation devices make positioning possible. On conveyors, monitors make it possible to monitor and visualise all sorts of processes. Today, control panels or flat screens are often an essential component of modern assembly workstations, too. Standard systems are generally designed for office applications. Industrial environments push these monitor mountings to their limits. For example, they normally can carry loads of only six to twelve kilograms and are not robust enough for use on machines, systems or assembly workstations.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF NRC type clamps were designed for the noise and vibration reducing installation of pipes and tubes with the most common outside diameters between 6 and 42 mm and ¼ to 1 ½ inch respectively. The working principle is based on clamp bodies made from Polypropylene (colour: black) following the Standard Series according to DIN 3015 (part 1) with a specially shaped, two-part elastomer insert, which mechanically absorbs vibrations in the pipe and as a result reduces noises arising to a minimum. The insert is in particular distinguished by how little of its surface is in contact with the pipe and clamp body, and as a result is far more effective than the previously known solutions. The tongue-groove contour of the insert and body, which is reversed and thus diverges from DIN 3015, enables the system to be used for the widest possible range of pipe diameters per clamp size, which contributes to flexibility and versatility. STAUFF NRC Clamps are completely compatible with the...

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: E0424 Manufacturer: Mogensen Description: Vibration Screen

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: S 48 C Manufacturer: Sweco Description: Vibration Screen

Request for a quote

CENTRIMAX - WINKELHORST TRENNTECHNIK GMBH

Germany

Type: 800 Manufacturer: Sweco Description: Vibration Screen

Request for a quote

TEST GMBH

Germany

As an extension to the friction testing machines TesT offers vibration testing machines for testing according to "Junker". Primarily, these machines are used for dynamic tests of safeguarding characteristics of fastening elements under transversal load (e.g. DIN 65151). A further development allows testing of larger screws, currently up to M42.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller.The device consists of an acceleration sensor, a controller unit and the output interface PROFIsafe over PROFINET for output of the acceleration values. Thanks to its high resistance to vibration and shock - more than the defined measuring range -, the sensor is suitable for use in areas with rough environmental conditions.Electrical connection is carried out using three connectors.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

The sensor system is intended as a component for use e.g. in wind power plants to measure and evaluate vibrations in the mast head. Registration of dynamic accelerations by means of MEMS sensors (Micro-Electro-Mechanical System) with subsequent digitisation by a controller. The device consists of an acceleration sensors, a controller unit and three types of output interface. Data output is carried out via two analogue interfaces with 4 ... 20 mA plus CANopen and via 4 relay contacts (currently 1 error relay contact). The NVA is parameterised via the CANopen interface. This is not galvanically separated. The sensor is equipped with a filter circuit to protect against fast transients and surge voltages of up to 2 kV in the supply. The protection types are IP 69K (housing) and IP 67 (connector/socket). With its good vibration and shock values, the sensor is suitable for use in areas with rough environmental conditions.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

The specialist among the all-rounders The CM series is best for processing large, heavy and sensitive workpieces. They are available in seven configurations with bowl volumes ranging from 115 to 1,000 litres. You can also choose from a wide range of accessories – such as for sound deadening or metering – to ensure that the CM circular vibrator fits your requirements precisely. Processing sensitive workpieces To ensure that your sensitive workpieces are processed gently, we have purposely not fitted the CM series with a screening unit. Depending on your individual processing goal, you can choose a moving separating plate and pneumatic bowl outlet. These both help keep sensitive components apart so they do not damage each other. The benefits at a glance No screening unit 115 to 1,000 litres gross volume Flat bowl bottom Pneumatic bowl outlet (optional) Moving separating plate (optional)

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Efficient mass finishing for the toughest requirements With a circular vibrator from our CB range, you get a mass finishing machine that works efficiently and achieves perfect processing results. The working channel is helically shaped and allows you to gently process your workpiece whilst ensuring high material abrasion. Gate clearing at the push of a button By pressing a button on the unit, you can quickly reverse the motor's direction of rotation before separating your workpieces from the abrasive media. This ensures that no workpieces or abrasive media are left on the gate that could get trapped between the separator flap and the working channel. Ideally suited for ball polishing and pressure deburring The CB circular vibrators stand out thanks to their robust steel construction and reinforced imbalance drive in the ball polishing configuration. This makes them ideal for ball polishing and pressure deburring with blasting medium.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

OUR ENTRY-LEVEL MODEL – EFFICIENT AND COST EFFECTIVEThe circular vibrators of the CF series are a perfect and simple introduction to mass finishing. The seven different configurations, with a range of different bowl sizes, offer excellent efficiency and maximum cost effectiveness. The CF circular vibrators are easy to operate and can be expanded with accessories for sound deadening or metering, for example. PROCESSING AND SEPARATION – SMOOTH MASS FINISHING The work bowl with an evenly rising floor is perfect for processing your workpieces, as the zero-maintenance vibration flange motor works at two different speeds. The pneumatic separator flap and long separation zone allow you to gently separate your workpieces from the abrasive media. This creates a smooth mass finishing process with excellent results.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

POWERFUL AND EFFICIENTThanks to their "Multivib" drive, the TMV range of trough vibrators ensures intensive workpiece processing throughout the entire bowl length. The extremely powerful drive also makes the machines suitable for ball polishing and pressure deburring. VARIOUS BOWL SIZES The modular series of the TMV range allows you to select the right bowl size for your requirements. This helps you save both costs and energy when processing your workpieces. Bowl widths: 410, 550, 650 and 850 mm Bowl lengths: 1,750, 2,600, 3,450, 4,300, 5,150, 6,000 and 6,850 mm SOUND DEADENING ENSURES LOW NOISE LEVELS Noise levels can be high, especially in a hall. That is why the TMV trough vibrators are fitted with a sound deadening lid, with complete sound deadening housings also available. Larger systems also feature walk-in sound deadening cabins.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

ROBUST, COST EFFECTIVE AND VERSATILEWith a trough vibrator from our TFM range, you get a mass finishing machine that can trowalize large and sensitive parts as required. Alongside an excellent processing result, this machine stands out above all thanks to its great-value purchasing costs. The bowl can also be supplied with a rubber lining. WITH U OR PEAR-SHAPED WORK BOWL TFM vibrators are supplied as standard with U-shaped work bowls with straight walls, which can also be ordered with integrated wedge profile for better mass circulation. Pear-shaped work bowls with double-retracted walls are also available for even greater robustness. VIBRATION VIA CONVENTIONAL IMBALANCE MOTORS Powerful conventional imbalance motors generate the imbalance in the trough vibrators. Your TFM vibrator will have one or two imbalance exciters depending on its size.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

!!!Not suitable for drying animal or vegetable products!!! VIBRATION DRYINGThe G-series dryer gently circulates your workpieces by means of vibration, together with the drying medium. The heated drying medium absorbs the moisture from your workpieces. In addition to drying your workpieces, the relative movement between them and the medium also has a polishing effect. PROTECTING YOUR SENSITIVE PARTS The bowl channel pitch is helically shaped and has no ramp, making the G dryer especially gentle when handling your workpieces. The high heating power is fully adjustable. The heater with replaceable heating elements is assembled separately from the vibrating section. To ensure your working environment is protected from dust, the dryer can also be fitted with a dust extractor.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

Robust mass finishing machines with separation zone The CD series of circular vibrators are robustly built and stand out thanks to their wide range of potential uses. From polishing and smoothing to deburring, the integrated screening unit helps easily separate workpiece and abrasive media using a manually or pneumatically powered separator flap. The CD circular vibrators are available in configurations from 110 to 1,200 litres of gross volume. Perfect configuration for large workpieces Thanks to the flat bowl bottom and the large opening between the bowl bottom and the separator flap, processing your large and sensitive workpieces is easy. CD circular vibrators also have a large separation zone for simple separation of flat components. The benefits at a glance — Integrated screening unit — Manually or pneumatically powered separator flap — 110 to 1,200 litres gross volume — Flat bowl bottom — Extra-long separation zone

Request for a quote

PCB PIEZOTRONICS GMBH

Germany

Current loop powered vibration transmitters enable cost-effective and permanent monitoring of machine vibrations. They provide a standardised 4 ... 20 mA output signal, which is proportional to the RMS or peak value of the measured vibration amplitude. The transmitters are connected to existing, free inputs of a PLC or a process control system. These then issue a warning message when a preset vibration level is exceeded or switch off the machine in an emergency. — Measuring range 0 ... 25.4 mm/s — Output range 4 ... 20 mA — Frequency range 3 ... 1,000 Hz — 2-pin connection socket on top. For an individual offer, please contact us directly.

Request for a quote

PCB PIEZOTRONICS GMBH

Germany

When using vibration transmitters, the vibration evaluation and the fault switch-off are outsourced, i.e. the alarm thresholds are parameterised in a separate evaluation unit or in a PLC that can record the trend development. Transmitters are current loop powered and output a normalised current signal corresponding to the vibration, which is then scaled in the system controller. The vibration transmitters of the 64x series are available with different measuring ranges and quantities (vibration velocity according to ISO 10816, vibration acceleration and vibration displacement, among others) that are related to the respective application. — Vibration transmitter with current output corresponding to the peak value of the vibration velocity — Measuring range 0 ... 12.7 mm/s — Output range 4 ... 20 mA — Frequency range 3 ... 1,000 Hz — 2-pin connection socket on top For an individual offer, please contact us directly.

Request for a quote

PCB PIEZOTRONICS GMBH

Germany

The low-cost High Temperature ICP®/ IEPE accelerometer, model HT602D01, is ideal for vibration measurements in higher temperature applications, including the paper, plastics and steel industries. These high temperature ceramic shear ICP® accelerometers feature a 2-pin MIL-C-5015 side-exit connector in a low-profile package. They can be used in environments with temperatures up to +325°F/+163°C. The sensing element of these accelerometers provides a sensitivity of (±10%) 100 mV/g (10.2 mV/(m/s²)) with a frequency range of (±3dB) 30 to 480000 cpm (0.5 to 8000 Hz). — Industrial ICP® vibration sensor — Continuous operating temperature up to 163 °C — With through hole — Measuring range 50 g — Sensitivity 100 mV/g — Frequency range 0.8 ... 8,000 Hz — Single-point calibration at 100 Hz — 2-pin connection socket on the side Please contact us directly for an individual offer.

Request for a quoteResults for

Vibrators - Import exportNumber of results

38 ProductsCategory

- Sensors (6)

- Accelerometers (6)

- Adjustment - machine tools (6)

- Anti-vibration supports (3)

- Vibrators, industrial - installations (2)

- Inductive sensors (2)

- Cylinders, hydraulic (1)

- Measurement and control instruments (1)

- Heating, industrial - installations and equipment (1)

- Waste sorting - machines and equipment (1)

- Weighing and dosing equipment (1)