- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thickness measurement

Results for

Thickness measurement - Import export

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Thickness measurement on plastic film samples requires automatic transport of the film strips through the measuring device, allowing for the flexibility of the material being measured. The desktop version of the VDM measuring station can be equipped not only with the pure measuring device, but also with PC-aided evaluation and graphic representation of the measurement results.

Request for a quote

INFICON GMBH

Germany

The Best Measurement Precision Possible for OLED Applications Cygnus 2 Thin Film Deposition Controller provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your OLED process. Cygnus 2 uses our ModeLock frequency measurement system to provide stable, high-resolution rate and thickness measurement with an industry-leading rate resolution of .00433 Å/s every 1/10 second. No other quartz crystal controller has the performance, quality, and features of Cygnus 2, allowing you to make excellence repeatable. 1 Å for 0 to 9.999 kÅ 10 Å for 10.00 to 99.99 kÅ 100 Å for 100.0 to 999.9 kÅ 1 kÅ for 1000 to 9999 kÅ 0.001 for 0 to 9.999 Å/s 0.01 for 0 to 99.99 Å/s 0.1 for 100 to 999.9 Å/s 100 – 230 V (ac) +/- 15% 50 / 60 Hz +/- 3 Hz (1) Tooling/density = 100/1, fundamental frequency = 6 MHz (2) Varies according to process; figures reflect typical accuracy (3) Maximum configuration of...

Request for a quote

INFICON GMBH

Germany

MAKING EXCELLENCE REPEATABLE Feature-Rich IC6 Provides the Best Measurement Precision Possible The IC6 Thin Film Deposition Controller provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your deposition process. The IC6 uses our ModeLock frequency measurement system to provide stable, high-resolution rate and thickness measurement with an industry-leading rate resolution of 0.00433 Å/s every 1/10 second. No other quartz crystal controller has the performance, quality, and features of the IC6, allowing you to make excellence repeatable. 1 Å for 0 to 9.999 kÅ 10 Å for 10.00 to 99.99 kÅ 100 Å for 100.0 to 999.9 kÅ 1 kÅ for 1000 to 9999 kÅ 0.001 for 0 to 9.999 Å/s if rate filter time setting is 10 seconds or greater 0.01 for 0 to 99.99 Å/s 0.1 for 100 to 999.9 Å/s 100 – 230 V (ac) +/- 15% 50 / 60 Hz +/- 3 Hz (1) Tooling/density = 100/1, fundamental frequency = 6 MHz (2)...

Request for a quote

INFICON GMBH

Germany

The SQM-160 uses proven INFICON quartz crystal sensor technology to measure rate and thickness in thin film deposition processes. Two sensor inputs are standard and four additional sensor inputs are optional. Two recorder outputs provide analog rate and thickness signals. Sensor inputs can be assigned to different materials, averaged for accurate deposition control in large systems, or configured for a dual sensor. The rate sampling mode allows a shuttered sensor to extend sensor life in high rate processes. Rate displays of 0.1Å/s or 0.01Å/s are user selectable. In addition, Frequency or Mass displays can be selected. Four relay outputs allow the SQM-160 to control source or sensor shutters, signal time and thickness setpoints, and signal crystal failure. Digital inputs allow external signals to start/stop and zero readings. Standard: RS-232; Optional: USB or Ethernet Standard: RS-232; Optional: USB or Ethernet Class 1 equipment, 73/72/EEC LVD, 89/336/EEC ECD Class 1...

Request for a quote

RALF LANG MASCHINENBAU GMBH

Germany

Handling the friction and steel discs into the measuring system from storage 360° laser measurement of the thickness of friction and steel discs Stacking discs with the respective high points offset to each other Measuring the disc pack for stacking height (pack class) and plane parallelism

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

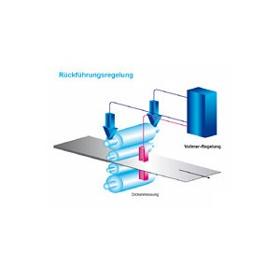

The high-speed servo-hydraulic control of the mill screwdown closes the loop: The thickness values measured precise to the micrometre form the basis for quick and precise control. Vollmer offers solutions for all control concepts from simple feedback control through to complete mass flow control or Direct gap contol for rolling of wedge-shaped strip and in tandem mills. Vollmer supplies the complete control system – from the sensors through the control technology right up to the hydraulics and the cylinder – from a single source. For our customers that means having just one contact partner – in short: A one-stop solution.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

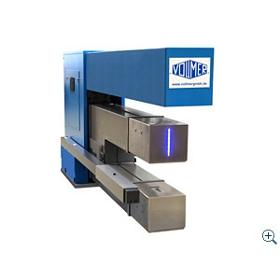

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The radiometric gauges from Vollmer operate contact-free and measure from a safe distance. They are characterised by their extremely narrow design: With some systems the C-frame is only 120 mm wide. The X-ray systems from Vollmer have digital detectors which give them extremely low noise values. Vollmer supplies the systems with high-quality ceramic tubes and the necessary cooler. The isotope systems also have digital detectors. A particular feature of the Vollmer systems is that the radiation source is located in a special tungsten drawer that can be easily removed from the gauge. Alloy compensation is made either in the classic manner using calibration plates or alternatively at the computer according to the customer's chemical alloy analysis or simply with a small contact thickness gauge that measures the absolute thickness at the start of the pass and transmits this value to the radiometric thickness gauge.

Request for a quote

IPF ELECTRONIC GMBH

Germany

Capacitive proximity switches are contact-free sensors. They detect metallic and non-metallic objects, regardless of whether they move or not. The achievable sensing range of the devices depends on the object material, its dimensions and the response sensitivity, which is set via a potentiometer. The vibration-resistant sensors can be approached laterally or frontally. Capacitive proximity switches are used for presence detection (e.g. sealing detection), positioning (e.g. PET bottles), counting (e.g. plastic caps), level detection (e.g. lubricant) or distance measurements (e.g. thickness measurement) of solid and liquid materials.

Request for a quoteResults for

Thickness measurement - Import exportNumber of results

12 ProductsCompany type