- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel rings

Results for

Steel rings - Import export

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

Mechanical parts - washers.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These are the pin ring made by stainless steel,which is the accessories used for sensor.

Request for a quote

SHENZHEN PROMOSTAR HARDWARE CO.,LTD

Germany

These the accessories used for machines.

Request for a quote

BORNEMANN GMBH

Germany

Steel types, also called type stamps, can be produced in all dimensions. The design is flexible: type stamps with or without groove, with labelling groove, in T shape (T type) and L shape (L type) as well as conical or segment types, which are put together as a ring. Cylindrical steel types can also be produced. The font size is guided by your drawing. The type stamps are hardened and annealed in accordance with the purpose and can be used immediately. Labelling is also possible in unmistakable fonts or with rounded-off engraving in addition to standard designs. Also possible are point font or low stress to avoid cracks in the stamping material.

Request for a quote

IGUS® GMBH

Germany

Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) iglidur® PRT slewing ring plain bearing data d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: 1 Aluminum, hard anodized 2 iglidur® J sliding elements

Request for a quote

SCHULZ STANZTECHNIK GMBH

Germany

Material Schulz Stanztechnik manufacturers these axial ball bearings using the materials suited to the specific application. For the housing, steel, brass or stainless steel are used; for rings, steel or stainless steel which is always hardened. The balls are made of chrome or stainless steel, which is also always hardened. All material combinations – depending on their conditions of use – are possible for the assembly of the individual parts. Various surface coats for the individual parts can be supplied as well as finished bearings: brass which is uncoated or nickel plated; steel and stainless steel which is uncoated, zinc plated or nickel plated. All bearings are available lubricated or unlubricated. Structure DLG100 axial ball bearings consist of sheet metal housing, two hardened rings as well as hardened precision balls. Due to their structure, we refer to them as an encapsulated, full ball design.

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Round, steel waste basket with 30 mm wide perforation ring. Capacity: 15 litres. • Round waste paper basket • Capacity: 15 litres • Made from scratch-proof, epoxy resin-coated steel • With a 30 mm wide decorative ring of perforations • Suitable for use in offices, hotels and other prestigious spaces

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our KIS hybrid bearings combine the best of two worlds - the robustness of classic rolling bearings (or stainless steel bearings) and the efficiency of state-of-the-art materials. With an optimised combination of high-quality steel rings and precise ceramic balls, our hybrid bearings offer outstanding strength and durability. Rolling elements made of ceramic offer a current-insulating property. These hybrid bearings have the same dimensions as comparable all-steel bearings and can significantly improve the reliability and robustness of machinery and equipment. In particular, they show their advantages in applications where the bearings are confronted with contamination from abrasive particles, insufficient lubrication, vibrations or current passage. At KIS, we optimise our materials for hybrid bearings to ensure flawless performance in applications under critical conditions at all times.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

Westfälsche Drahtindustrie GmbH uses highly efficient plant technology at its Salzgitter site to produce cold-ribbed reinforcing steel (CR) in rings and coils, as well as structural steel mesh. Thanks to special wire rod primary material for our CR products, which we have developed in close cooperation with our suppliers, our reinforcing wire achieves first-class technical values, particularly in terms of elongation and the Re/Rm ratio The advantages for the user: easy processing and dimensional accuracy of the hangers. Seamless quality monitoring from the wire rod to the finished product by our own quality centre and our external monitoring centre (MPA Dortmund) guarantees the highest level of lasting quality and safety.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

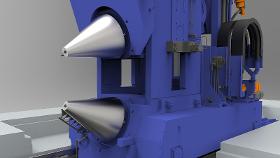

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

With the ring rolling mill Siempelkamp completes its range of products for the manufacture of rings. From forging the pre-forms to manufacturing the ring blanks to ring rolling, we supply everything from a single source. Siempelkamp’s ring rolling mill manufactures seamless rings made of steel and special materials such as nickel-base, titanium, or aluminium alloys using maximum radial and axial pressing forces. The radial pressing force is hydraulically generated and applied to the part via a mandrel roll. Radial rolling is carried out by reducing the roll gap between the driven external roller and the mandrel roll. The axial pressing force is also hydraulically generated and applied to the part via the upper axial roller. Axial rolling is carried out by means of the vertical forward feed of the upper axial roller. A centring device provides for the correct position of the ring during the rolling process.

Request for a quote

SANHA GMBH & CO. KG

Germany

The SANHA®-Therm installation system consists of tried and trusted SANHA®-Therm press fittings from carbon steel (c-steel) with a black sealing ring from EPDM (ethylene propylene dien rubber monomere) and SANHA®-Therm carbon steel pipes according to EN 10305-3. The carefully manufactured installation systen and its components offer an economically attractive solution for closed heating installations. At the same time, SANHA®-Therm ist especially well suited for pressurised air and fire extinguishing systems according to EN 10346 (DZ version). The variant "Contiflo" also offers galvanized system pipes which are characterized by being easy to bend. Our C-steel system is furthermore available as a LABS*-free version (series 27000).

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 124510, flache Bauhöhe data of the Tension rings verzinkt, DX 51, überlappt, 1.2 mm Diameter 571 mm Application Metallfässer

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 124151 data of the Tension rings DX 51, 1 mm, nicht überlappt Diameter 571 mm Application Metallfässer

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 123943 data of the Tension rings verzinkt, 1 mm, nicht überlappt Diameter 400 mm Application Metalfässer

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

EUROTEC SPANNRINGE GMBH

Germany

Clamp 124151 data of the Tension rings 1.5 mm, verzinkt, überlappt Diameter 571 mm Application Metallfässer

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp Ozen 134260 rechts Ozen 134261 links data of the Tension rings Material: DX 51, 1mm Diameter 571 mm Application Metallfässer

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 123943 data of the Tension rings Verzinkt, DX 51, 1 mm, überlappt Diameter 330 mm Application Metallfässer

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 123943 nach DIN 6644 data of the Tension rings 1.25 x 26 mm, DX 51 Diameter 360 mm Application Metalltrommel

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp 124242 data of the Tension rings 40 x 1.5 mm, sendz. verzinkt, überlappte Ringenden Diameter 571 mm Application Rekonditioniertes Stahlfass

Request for a quote

EUROTEC SPANNRINGE GMBH

Germany

Clamp komplett in Materialstärke 2mm data of the Tension rings verzinkt, DX 51, 100mm überlappt, 2 mm Diameter 571 mm Application Metallfässer, flüssigkeitsdicht

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Air exchange in sealed housings? No Problem! Our pressure equalisation elements (formerly Gothe & Co. GmbH) have proven themselves reliably worldwide. High temperatures and adverse environmental influences provide continuous pressure fluctuations in sealed housings – protect your sensitive electronics and improve the lifetime of electronic devices with our pressure equalisation elements. Reliable reduction of condensate formation Protection of harmful fluids and particles Special Features Flat construction Easy installation (from inside or outside) 100% Salt retention capacity Very robust Diverse versions Air passage of up to 400 ml/min Technical Data Mounting body/cap brass (optional nickel-plated, chrome-plated or stainless steel) Membrane ePTFE (oleophobic) O-Ring NBR (optional EPDM, FKM or silicone) Water ingress pressure > 0,6 bar Protection class DIN EN 60529 IP66, IP68 (installed) Acceptable temperatures - 40 °C … + 80 °C (150°C temporary)

Request for a quoteResults for

Steel rings - Import exportNumber of results

25 ProductsCategory

- Wires and cables, steel (3)

- Bearings, ball (1)

- Bearings, roller (1)

- Driveshafts and micro-motors - electric (1)

- Inductive sensors (1)

- Office machines and equipment (1)

- Pipe and tube fittings - ferrous metal (1)

- Pressure regulators (1)

- Rolling mills - ferrous metals (1)

- Seals (1)

- Weaving - machinery and equipment (1)