- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special seals

Results for

Special seals - Import export

ROLLON GMBH

Germany

International patent registered for the CLEAN ROOM SYSTEM line (DIN EN ISO 14644-1) The CLEAN ROOM SYSTEM units are linear actuators with belt driven transmission and are specifically designed for Clean Room applications They are supplied with a certificate issued by the IPA Fraunhofer Institute in Stuttgard, which certifies compliance with class ISO 3 (DIN EN ISO 14644-1), or with class Fed Std 0.01 (FED 209 E). The system prevents particles from being discharged in the environment where the linear unit is located. This has been achieved by using a special straight seal that closes the horizontal opening where the slider moves, as well as by the operation of a 0.8 vacuum pump connected to 2 vacuum pipes located inside the drive head and the idle head. The system allows vacuum to be generated inside the unit so that any particles released when the system is operating are sucked towards the air filtration areas. Clean Room System linear actuators components are all made of...

Request for a quote

IGUS® GMBH

Germany

Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) iglidur® PRT slewing ring plain bearing data d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: Special properties: Slewing ring with high stiffening Simple installation, replaceable, maintenance-free sliding elements made of iglidur® J High wear resistance Available as aluminum or stainless steel version V4A (stainless steel only for PRT-01-60 and PRT-01-100) d [mm]: Special properties: Suitable up to 180°C, high chemical resistance For all 5 standard dimensions of style 01 Body in aluminium or stainless steel, sliding parts in iglidur® H1 d [mm]: Special properties: Free of lubrication and maintenance. For use in extreme dirt. Corrossion-resistant Robust and ready to install Available in dimensions 60 and 100, oneside (-D) or boothside (-DD) seal d [mm]: Special properties: For use in the food industry with gliding elements made of FDA-compliant iglidur® A180 instead of iglidur® J standard. Can be naturally combined with the stainless steel versions of the slewing ring bearing. Lubricant- and maintenance-free For use in extreme dirt. Ready to install Rugged and wear resistant Application areas: Food processing industry d1 [mm]: 1 Aluminum, hard anodized 2 iglidur® J sliding elements

Request for a quote

R+L HYDRAULICS GMBH

Germany

Large bore dimensions High torque Topclass seal system Special types High misalignments

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1,870 Nm/cycle Stroke 48.6 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 1,870 Nm/cycle Stroke 48.6 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the LT (low temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of -50 °C to +66 °C in order to safely and reliable damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 370 Nm/cycle Stroke 23.1 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote_FA_IMG_Single-01-cut-Labels_RGB-L_EN_55500bd5.jpg)

ACE STOSSDÄMPFER GMBH

Germany

Self-Compensating Energy capacity 170 Nm/cycle Stroke 23.2 mm Further possibilities of use: Just like all MAGNUM types from the product family MC33 to MC64, the HT (high temperature) industrial shock absorbers are also made from one solid piece. They are characterised by the use of special seals and fluids. This means that these versions can even be used at extreme temperatures of 0 °C to 150 °C in order to safely and reliably damp masses and take away 100 % kinetic energy. There is no reason why these ready-to-install machine elements should not be used, even under the most unfavourable conditions. Additional benefits are their robust, innovative sealing technology, high energy absorption in a compact design, fixed positive stop and a wide damping range.

Request for a quote

REICH-KUPPLUNGEN ; DIPL.-ING. HERWARTH REICH GMBH

Germany

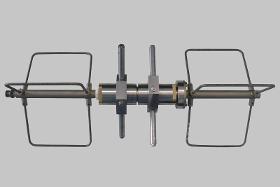

The barrel coupling consists of a sleeve provided with semicircular toothing around its internal diameter and a hub that is externally toothed in a similar way. A series of cylindrical barrels, of hardened steel, are inserted in the holes formed by this toothing to act as power transmission elements. Covers with their corresponding special seals serve to assure the perfect tightness of the inner zone, preventing the penetration of dust and guaranteeing the continuity of the necessary lubrication. The most important characteristics and adcantages of barrel roll couplings: for alignment error compensation for ease of assembly especially wear-resistant with high durability minimises effect of alternative bending of the torque on the toothing designed for bearing large radial loads by distributing them over large barrel support surfaces Perfect tightness of the inner zone prevent the penetration of dust We are glad to see that you are interested in our product line and are happy to...

Request for a quote

OPTIMEL SCHMELZGUSSTECHNIK GMBH

Germany

The CUSTOMline hot melt machine is the top solution for customized casting requirements. It is configured specifically according to customer requirements and can handle complex casting tasks with exceptional precision and efficiency. This machine is ideal for special applications where standard solutions are not sufficient. With the CUSTOMline you get a casting machine that is tailored precisely to the specific needs of your production process in order to achieve optimal results. product [hot melt application systems, hot melt coating machines for paper, hot melt, hot melt adhesives, hot melt packaging, hot melt adhesives, special machines for adhesive processing, hot melts, machines for gluing, machine for gluing, melt casting technology with hot melt, hot melt coating, gluing machines, special machines for casting, sealing, foaming, gluing, special packaging machines]

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

The PFLITSCH CABseal is used to feed pre-assembled and non-assembled cables, as well as pneumatic and hydraulic lines, simply and reliably into control cabinets, primarily, but also into enclosures and machines. To this end, their sizes and dimensions of the frames are compatible with the common standard cut-outs and hole patterns in control cabinets so that just a single CABseal frame is required per cut-out. The CABseal cable entry system consists of four different sized frames and a number of cable grommets that can be equipped in various constellations. The grommets are slotted at the sides to make it easier to insert cables. While the frame is made of hard and robust polyamide, we use a flexible elastomer for the cable grommets and their special sealing lips. To ensure the cables are properly sealed, the grommets are positioned in the frame and compressed when the upper part of the frame is screwed down.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Special applications have special requirements for connectors. For this field of application, CONEC developed water-tight D-SUB connectors with rating IP67. Owing to special sealing measures at the connector and the sealing frame, the high requirements are met. These connectors are used where dust and spray water occur and functioning of usual connectors would be negatively affected. These connectors are available as standard or high density in the usual pole number.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI; ideal for applications in which space is limited Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Compact design allows space-saving installation: ▪ Always 40 mm / 1.57 in shorter than Level Gauges SNK of the comparable nominal size ▪ Display either undivided (SNKK 127 ... 176) or subdivided by strut(s) into 2 (SNKK 254) or 3 sections (SNKK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual / electrical fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 5 nominal sizes from 127 mm / 5.00 in to 305 mm / 12.00 in ▪ Display either undivided (SNK 127 ... 176) or subdivided by strut(s) into 2 (SNK 254) or 3 sections (SNK 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Aluminium, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Float made of Polyamide (PA) ▪ Sealings made of FPM (Viton®) Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials are available on request. Electrical Specifications ▪ Magnetic float activates switch when fluid level drops below contact level within 60 mm / 2.36 in of lower banjo bolt ▪ Available as a break contact...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Visual fluid level indication in hydraulic reservoirs with maximum tank pressures not exceeding 2 bar / 29 PSI Nominal Sizes and Designs ▪ 6 nominal sizes from 76 mm / 2.99 in to 305 mm / 12.00 in ▪ Display either undivided (SNA 076 ... 176) or subdivided by strut(s) into 2 (SNA 254) or 3 sections (SNA 305) Media Compatibility ▪ Suitable for use with Mineral and Petroleum based hydraulic fluids (HL and HLP) Materials ▪ Housing made of Steel St 12, black powder coating ▪ Sight tube and plugs made of Polyamide (PA) ▪ Sealings made of NBR (Buna-N®) ▪ Scale plate made of PVC Special sight tube materials for improved UV or chemical resistance and use with special media (such as bio-degradable fluids, diesel oils, gasolines, etc.) as well as special sealing materials, e.g. FPM (Viton®), and scale plate materials, e.g. Aluminium, are available on request. Technical Data ▪ IP 65 protection rating: Dust tight and protected against water jets (IP 67 on request) ▪ Operating temperature...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Material Carbon Steel Surface Finishing Zinc-Plating and Thick-Film-Passivation (Chrome III) Standard Seal Material(s) Special compound Working Temperature -35° C ... +130° C / -31° F ... +266° F Valve Design Flat Face Connection Push and actuate Push Sleeve Disconnection Actuate Push Sleeve Connect Under Pressure not allowed Application Rescue and Tensioning Hydraulics ISO Interchange -

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KAMAT GMBH & CO. KG

Germany

The nozzle consists of two counter-rotating nozzle housings into which the nozzle tubes are inserted with a connection for screw-in round jet nozzles. A special packing sealing system inside the nozzle housings ensures protection during operation and prevents the ingress of contaminants. In front of and behind the nozzle housings are spacers (basket system) to prevent the nozzle tubes from hitting the well wall. In addition, for best cleaning results, the temperature of the medium should be between 3 and 30°C.

Request for a quote

ABS SAFETY GMBH

Germany

These particularly long sealant collars were specially designed for sealing up anchorage points on a bitumen roof surface. They are 300 mm long and available in two models: For anchors with or without an additional supporting tube (Ø 16 oder Ø 42 mm). The discs are 420 mm in diameter. The collars have also been marked with a series of practical notches which make it easier to shorten them. Sanded or slated - for bitumen roof surfaces Suitable for Ø 16 and 42 mm supports Extra-long: 300 mm Notches cut into the surface every 20 mm allow the tube to be shortened in a straight line Incl. shrink tubing Disc diameter: Ø 420 mm

Request for a quote

IBK WIESEHAHN GMBH

Germany

Developed by IBK Wiesehahn, the secondary friction connection seal with H-profile has created an area of application in the industrial branch. The successfull conzept of “secondary friction connection” is based on the separation of bracing and sealing. Every functionary of the seal meet only one function. The seal is made of hard metal-profile and elastic sealing-material. The sealing-material is measured, that after reaching the block storage, the recovery behavior fully exists. A overpress of the sealing-material is basically excluded. Benfits of IBK SAFE-H® Seal: Secondary friction connection (block storage) Seal is chambered (secured against exhaust) High resilience of the flange connection Indenpendently pressure stage dimensions Easier to install regarding centring gauges Simplified warehousing High temperature resistance (up to 1000°C) High pressure resistance (up to 525 bar) Possibility of redefinition of the sealing zone with repair set

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. Product Range: - DVGW tested, see separate brochure - Punched, cut seals - Plates, foils - Semi-finished items - Form articles Benefits: - Highest chemical resistance - Insoluble and does not swell in organic or anorganic solvents - Resistant to the weather - Temperature range -190 to +250 °C - Highly anti-adhesive, does not stick - Resistant to hydrolysis Common fillers: - Quartz - Glass - Carbon / Graphite - Bronze - or without filters Fillers reduce the cold flow, lead to higher resistance to temperature and media, improve thermal conductivity and increase resistance to abrasion and pressure levels.

Request for a quote

IBK WIESEHAHN GMBH

Germany

We develop and manufacture special seals for power stations, for the chemical and petrochemical industries, for machinery and pipeline construction. In other words, seals that provide the greatest possible reliability even under extreme operating conditions (pressure, heat, cold, aggressive media) – at temperatures from -200 to +1.000 °C. The patent solution IBK-SAFE-H® developed by us has been used for years in the chemical industry, in machinery construction and in nuclear powerstations and defines the state of the art in its discipline Type Profile - Flat gasket IFD / with inner metal border IFDI - Rubber-steel gasket IGSD / with O-Ring IGSP - Non-load-transmitting rubber-steel gasket IGSKN - Corrugated gasket IWD / with centerring IWZ - spiralwound gasket ISD - spiralwound gasket with inner centerring ISI - Spiralwound gasket with inner and outer centerring ISIA - Grooved gasket IKD / with centerring IKZ - Convex grooved gasket IBKD / with centerring IBKZ

Request for a quote

BAUER GMBH

Germany

-Controlled discharge of solids special manually operated scissor lock 300 x 300 mm -frame made of steel tubing -hopper made of steel plating with reinforced edging Types available Type SR -2 swivel + 2 fixed polyamide castors Ø 180 mm, 1 swivel castor with brake, - construction height 220 mm Type SG -fork sleeves inside dimensions (wxh) = 175x65 mm, distance 565 mm -stacking corners Type SRE 2 swivel + 2 fixed polyamide castors Ø 180 mm, 1 swivel castor with brake - construction height 220 mm fork sleeves inside dimensions (wxh) = 175x65 mm, distance 565 mm Types SR-D, SG-D, SRE-D design see above but with slide closure with a special seal on the hopper floor, for manual use, opening 300x300 mm, preferred for fine-grained bulk materials -spray painted or hot-dip galvanized -Volume (approx.) in l: 375 / 600 Accessories -galvanized lid, removable

Request for a quote

HEBMÜLLER GMBH

Germany

We supply molded seals and special elastomer components made of special compounds based on ACM / AEM, NBR / HNBR and FKM / FPM for various hydraulic applications in mechanical engineering.

Request for a quote

BLUESENS GAS SENSOR GMBH

Germany

BlueVCount measures gas volumes in reactions of all kind. It is applicable for fermentations, degradation studies, substrate comparison studies, wastewater treatment, bioethanol or hydrogen production and is especially helpful in bio methane potential (BMP) determinations in industry and academia. Gas volume measurement delivers important information about the process and helps to optimize yields and process procedures. BlueVCount is a volume measuring unit with a 1 ml cylinder that is equipped with an oil (special) sealed magnetic piston. It counts how often 1 ml gas comes through the cylinder and reports it to the integrated display or via Modbus RTU to a software (e.g. BlueVIS). A minimum flow is not necessary.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

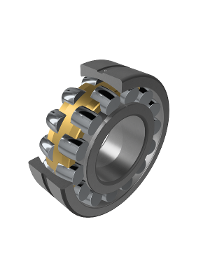

With decades of experience, we manufacture spherical roller bearings at KIS that can support large radial and axial forces in both directions. The perfect solution for applications that have to withstand massive loads. Due to the design of two rows of pendulum-shaped rollers in a common, hollow-ball raceway in the outer ring, our spherical roller bearings can support large radial and also axial forces. This makes them perfect for applications that have to withstand high loads and shocks and compensate for shaft bending or misalignment. In addition to conventional spherical roller bearings (which have no seal and have either a tapered or cylindrical bore), there are also application-specific variants developed for special requirements (e.g. sealed spherical roller bearings or bearings with optimised load ratings). Spherical roller bearings offer high performance and efficiency and are available in a wide range of sizes and designs.

Request for a quote

BEULCO GMBH & CO. KG

Germany

— brackets are equipped with cross slots to guarantee an ideal adjustment of the installation set — Length compensation fittings to find the optimum position of the water meter — Screw connections with roughened external thread for even more tightness QUICKTURN piston valves — easy operation by ergonomically shaped handles — fast operation with just a few turns from "open" to "closed" — Direction of rotation indication on the handle — The label on the handle allows the clear line marking — non-rising top — Dead space top — Functional parts of the piston valve maintenance-free and permanently lubricated — Deposition-resistant sealing piston by special profile All materials meet the requirements of the Federal Environmental Agency and are approved for drinking water.

Request for a quote

BEULCO GMBH & CO. KG

Germany

Plug-in connector for drinking water, water and gas. The material-friendly connecting technique enables that the pipe is only stressed as the relations of pression and torsion demand. Premature wear due to overstressing of material and subsequent troublescan be excluded. The metal clamping claw enables a torsion-free assembly by its positioning. The connector can easiliy be dismounted – all components can be reused without problems. For the application in the field of gas the connector has an additional insert pipe to stabilise the pipe. For the application in the field of drinking water the connector has the proven EPDM profile gasket which reliably seals minor damages on the surface. The plug-in connectors for the application in the fields of water and gas additionally have a special o-ring. The sealing and clamping functions are separated and independent which makes the connector extraordinarily safe.

Request for a quote

HYDROSTAR MESSTECHNIK GMBH

Germany

Our mechanical pressure switches are entirely “Made in Germany”. Hydrostar’s extensive and long product experience along with continuous improvements in hydraulic pressure measurements enables the production of high-quality, accurate and reliable mechanical pressure switches. These properties have proven themselves consistently worldwide. The core of the pressure switch line is the special extreme long-lasting sealing combined with the piston-springprinciple and its exceptionally accurate and reliable change-over switch. The minimum switching path with an additional throttle bore allows for a lengthy and durable life cycle. Another special feature is the potential adjustability of the pressure switch on client-side, even after the installation. Mechanical piston pressure switch for pressure monitoring Pressure range 5 to 350 bar Special Features Precise and Reliable Compact Design Change-over switch High overpressure security

Request for a quoteResults for

Special seals - Import exportNumber of results

32 ProductsCategory

- Seals (4)

- Rubber seals (3)

- Plumbing, domestic (2)

- Pressure regulators (2)

- Pressure switches (2)

- Coupling, pneumatic (1)

- Bearings, roller (1)

- Connectors, electronic (1)

- Control boxes - electric (1)

- Gears (1)

- Insulating seals (1)

- Internal transport systems (1)

- Nozzles - ferrous metal (1)

- Potting equipment (1)

- Scientific equipment and instruments (1)

- Silos, metal (1)