- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheets and plates

Results for

Sheets and plates - Import export

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

we process thin sheets, heavy plate, wear-resistant sheet and plate. aluminium sheets, stainless steel sheets, copper sheets, brass sheets and much more, with formates from 3000 to 8000 mm (118" to 315"), with thickness 1 mm – 180 mm (0,039" to 7") welded sheet metal structures, aluminium constructions, industrial profiles

Request for a quote

ANTHERMO GMBH

Germany

Temperation of fluids Pillow plates are used everywhere where liquids must be temperated. In dependence of application the liquids can be cooled or heated. Cause of this wide range of applications pillow plates are used in the process industry, in the cooling industry and in a lot of other industries. Pillow plates are also know as heat exchanger plates, evaporator plates, cooling plates /sheets and thermo plates / sheets. Pillow plates as air-/water-heat exchanger Additionally to the temperation of liquids pillow plates are also used as air-/liquid heat exchangers. In case of polluted or wasted air and if there are high demands for cleaning, more and more pillow plates are used as air-/water-heat exchanger. The large exchange surface and the good possibilities for cleaning are important features for this type of heat exchanger.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Firm hold in any position Demag DBM battery magnets are the ideal solution wherever you need to transport magnetisable loads safely and efficiently. They can be used independently of a power supply and are therefore highly versatile. Whether used as stationary units with wall or slewing jib cranes or as mobile equipment with cranes or forklift trucks, Demag DBM battery magnets allow you to transport loads weighing up to 4 tons easily and safely from A to B. DBM battery magnet -Universal application -Compact design -High safety and reliability -High load capacity -Loads are always safely picked up -Automatic charging control Universal application -Outdoor operation also possible with IP43 enclosure (power source, charger and control elements combined into one unit) -Single metal sheets or plates can be separated from the load by flicking the toggle switch -High load capacities

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

In the aerospace industry we specialize in the production of rolled aluminum plate and sheet materials for fuselage and wing structure components according to standard or customized specifications. The aerospace industry is building new aircraft to accommodate a growing number of air passengers and to replace older, less efficient planes with newer, more fuel-efficient models. Aluminum offers a high strength-to-weight ratio, energy efficiency, and high tolerance to extreme temperatures- making it an ideal material for the manufacturing of aircraft. It can also be recycled repeatedly, making it a good choice as manufacturers pursue sustainability initiatives. We have introduced new low-density alloys that represent an innovative step forward for aluminum in aerospace. Weight-savings from these new alloys translate into fuel efficiency and lower operating costs for the airline industry.

Request for a quote

ABS SAFETY GMBH

Germany

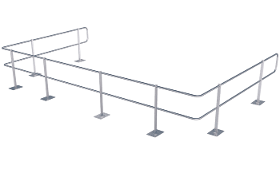

This guard rail, which is made of aluminium and stainless steel, is simply riveted onto the profiles of a sandwich roof surface. This high-quality, collective protection system comes with a set of watertight blind rivets which have been awarded national technical approval. The handrail is 1100 mm high. EN 13374:2013, A Distance between the posts: Max. 2.50 m Specially designed for sandwich and trapezoidal sheeting (positive/negative) For steel plating ≥ 0.45 mm Distance between the holes:: 180/250 mm or 280/333 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ABS SAFETY GMBH

Germany

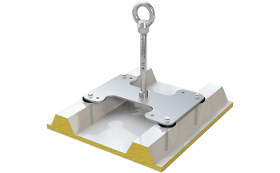

This anchorage point (Ø 16 mm) for sandwich sheeting is simply installed from above using 4 special toggle bolts. The anchorage eyelet, rod and base plate (372 x 200 mm) are all manufactured completely from stainless steel material. The special toggle bolts needed are included in the package. EN 795:2012, A + CEN/TS 16415:2013 Sandwich and trapezoidal sheeting (negative) For steel plating ≥ 0.5 mm Distance between the bores: 280 to 333 mm Installation materials included Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

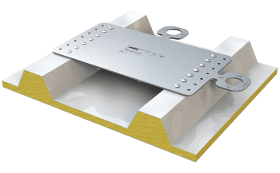

This extremely flat stainless steel anchor does not get in the way when stacking containers. Combine 2 ABS-Lock X-Flat devices to create a temporary lifeline system. The anchor is riveted onto the subsurface from above using 14 watertight blind rivets. The integrated sealant tape prevents water from seeping in. EN 795:2012, A + CEN/TS 16415:2017 Specially designed for sandwich and trapezoidal sheeting (positive/negative) For steel plating ≥ 0.5 mm Distance between the rows of pre-drilled holes: 180-250mm / 280-333 mm Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

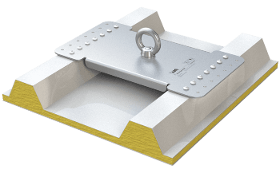

This stainless anchorage point can be installed on a range of different seams and is available in two models. Simply install this anchorage device from above using the stainless steel blind rivets provided. We also supply models for usage as an intermediate bracket or T-junction in a lifeline system. EN 795:2012, A + CEN/TS 16415:2017 Sandwich and trapezoidal sheeting (cold roofs) For steel plating ≥ 0.45 mm; Aluminium ≥ 0.8 mm Distance between the holes: 180-250 mm / 280-333 mm Installation materials included

Request for a quote

IBK WIESEHAHN GMBH

Germany

Graf-Flex-SP2 seals The Graf-Flex-SP-2 seal is a pointed sheet seal produced by a special process. The design of the seal is based on empirical values. Numerous tests have been carried out to verify the adhesion between the pointed sheet and the graphite coating as well as the surface quality, and thus the adhesion between the coating and the flange surface.The first phase of these tests led to special perforation of the carrier plate in terms of the geometric shape of the hole and hole distribution. The second phase took account of the adhesion of the seal to the surface of the flange and defined the surface quality of the graphite material. The values found in this way were transferred to the mass production process using a special procedure. . This consisted of a specially produced perforated roller for penetrating the sheet together with a special surface roller. Finally, the graphite coating is applied to the defined surface in the calendering process.

Request for a quoteResults for

Sheets and plates - Import exportNumber of results

11 ProductsCompany type