- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- points

Results for

Points - Import export

BS BODENSTECKDOSEN SYSTEMTECHNIK GMBH

Germany

Floor box 8810B made of polished stainless steel for 10 units. It can be installed at any point in the floor, as pipes are used for the line feed. Because of its low height, this version is particularly suitable for floors in old buildings. The rimless lid also closes when the plugs are inserted and is designed for sticking on floor coverings. Further equipment variants on request.

Request for a quote

RG + SCHWINGUNGSTECHNIK GMBH

Germany

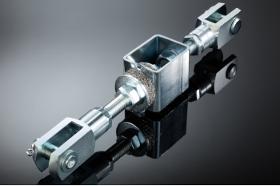

Vibration dampers of the series GAB are especially used to stabilize your pipe system. You can use these elements to absorb thermal expansion of the pipes, too. These elements are often used in the field of plant engineering. Depending on the chosen series you are able to couple your system with this elements by a welding profile or a fork head. RG+ offers these suspensions in the following designs: GAB-( )-2 with one fork head on each site GAB-( )-5 with one fork head on one site and a welding profile on the other

Request for a quote

VKF RENZEL GMBH

Germany

The "Stopper-Point" barrier is used in a wide range of applications. The flexible barrier post is easy to place and can be moved quickly and repeatedly. With a belt extension to all four sides, there are no limits in the barricading and demarcation. The belt can be extended to a length of 2.5 metres. Due to the dark colour, the belt easily separates from the posts and background so that the barrier cannot be overlooked. The belts remain securely hooked in during use. The high mobility of the barrier post is defined by its material properties. The entire stand is made of silver anodised aluminium. Due to the lightness of the aluminium the post weighs only 7.4 kg and is at the same time extremely stable. The stability is guaranteed by a base with a diameter of 33cm.

Request for a quote

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

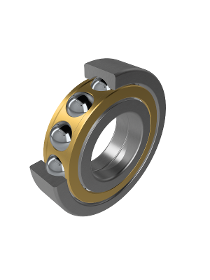

Are you operating an application requiring a bearing arrangement with high load carrying capacity with low-noise operation? Our durable four-point bearings are the perfect solution for this scenario and can support high axial loads as well as radial forces (relatively lower) in both directions. Four-point bearings are similar in structure to double-row angular contact ball bearings, but are much narrower in the axial direction due to a single raceway. The circular arc-shaped raceways in the inner and outer ring have opposite centres of curvature so that the balls contact the races at four points under radial load. If there is a predominantly radial load, four-point bearings should be avoided due to the higher friction in four-point contact. In assembly, one of the two races, often the inner race, is split to insert the balls. Since four-point contact bearings are often installed radially exposed, the outer rings can optionally be equipped with retaining grooves to prevent rotation.

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Drawer box for coffee capsules. Ideal for placing right underneath the coffee machine. • Modular storage box with two drawers for catering utensils • Can be placed underneath capsule and pad machines to save space • Provides easy access to coffee utensils (e.g. up to 70 coffee capsules) • Ideal for use in kitchenettes, lounge areas and meeting rooms

Request for a quote

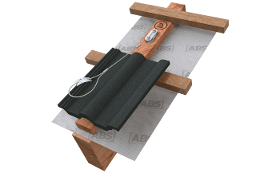

ABS SAFETY GMBH

Germany

For a high load-bearing capacity in any direction, simply insert this stainless steel anchorage point (Ø 16 mm) through a pre-drilled hole in a wooden beam and counter it on the other side. This anchor is available with and without a protrusion and can be installed on the ground, laterally or overhead. EN 795:2012, A + EN CEN/TS 16415:2013 Protruding and non-protruding models available Designed for load-bearing wooden structures Minimum rafter dimensions: 100 mm x 120 mm Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

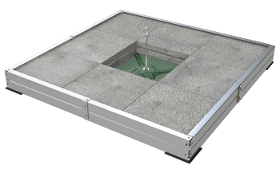

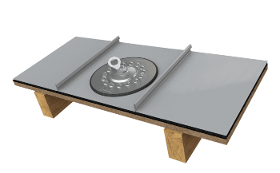

This anchorage device was specially-designed for flat roofs. It can be used as an anchor or system support and can be weighed down using concrete slabs (50 x 50 x 5 cm, not included) or gravel (not included). Its high-quality, stainless steel frame (150 x 150 cm) with aluminium crossbars is equipped with a central anchorage point (Ø 16 mm) - also made of stainless steel. EN 795:2012, E + CEN/TS 16415:2013 For flat roof pitches ≤ 5° Weighed down using 16 concrete slabs (ca. 448 kg) Weight incl. ballast: 483 kg | resulting roof load: approx. 214.7 kg per m² Anchorage point for 2 individuals Weighed down using gravel (ca. 450 kg) Weight incl. ballast: ca. 485 kg | resulting roof load: approx. 200 kg per m² Anchorage point for 1 individual (secures 2 individuals when used as an intermediate bracket in a lifeline system) Additional supporting tube required for usage as an end or corner post Incl. 5 EPDM patches to protect your roof membrane

Request for a quote

ABS SAFETY GMBH

Germany

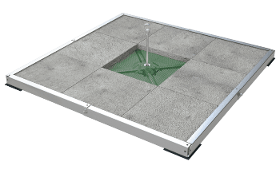

This cross-shaped anchor for flat roofs is weighed down using concrete slabs (50 x 50 x 5cm, not included). The design is based on a high-quality stainless steel frame (150 x 150 cm) with aluminium crossbars and a central, stainless steel anchorage point for one individual (Ø 16 mm). EN 795:2012, E For flat roof pitches ≤ 5° Weighed down using 8 concrete slabs (ca. 224 kg) Weight incl. ballast: ca. 245 kg; resulting roof load approx. 108.9 kg per m² Also designed for usage as an intermediate post in a lifeline system Incl. 5 EPDM patches to protect your roof membrane

Request for a quote

ABS SAFETY GMBH

Germany

Whether this device is left standing out in the open or integrated into your roof greenery, our ABS Weight OnTop Max anchorage device for flat roof surfaces has been approved for installation without penetrating your roof surface - simply by weighting it down (50 x 50 x 5 cm, concrete slabs not included). Please observe the installation instructions provided in the "abZ" (national technical approval: Z-14.9-824) For flat roof pitches ≤ 5° Weighted down using 40 concrete slabs (ca. 1.120 kg) | resulting roof load approx. 61 kg per m² If implemented as an end or corner post in a lifeline system, a special supporting tube needs to be used

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point, which comes with a base plate (150 x 150 mm), has been approved by the German Institute for Construction Technology ("DIBt"). It is installed on a steel structure and countered on the other side. The welded-on supporting tube (Ø 42 mm) easily withstands the pre-tensioning stress to which it is subjected when used in a lifeline system. Our standard package includes a set of installation materials. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2017 Base plate + welded-on supporting tube Incl.stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

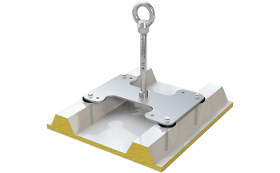

This anchorage point (Ø 16 mm) for sandwich sheeting is simply installed from above using 4 special toggle bolts. The anchorage eyelet, rod and base plate (372 x 200 mm) are all manufactured completely from stainless steel material. The special toggle bolts needed are included in the package. EN 795:2012, A + CEN/TS 16415:2013 Sandwich and trapezoidal sheeting (negative) For steel plating ≥ 0.5 mm Distance between the bores: 280 to 333 mm Installation materials included Add a supporting tube for usage as an end or corner post in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Install the base plate (200 x 200 mm) of this stainless steel anchorage point (Ø 16 mm) on a load-bearing steel structure and then counter it using 4 stainless steel bolts. This anchor has been awarded national technical approval by the German Institute for Construction Technology ("DIBt"). The bolts and counter nuts required are included in the package. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 Incl. stainless steel installation set Upgrade with a supporting tube for usage as an end or corner support in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

All you need to install this stainless steel anchorage point (Ø 16 mm), which is suitable for all directions of load, is an installation depth of at least 65 mm. The anchor base plate (200 x 200 mm) is fixed permanently to the concrete subsurface using the 4 drive-in dowels supplied. EN 795:2012, A + CEN/TS 16415:2013 Concrete ≥ C20/25 Installation depth required: Only 65mm Add a supporting tube for usage as an end or corner post in a lifeline system Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

This mobile door traverse provides your workers with a temporary anchorage option in a fall danger zone at a minute's notice. This robust steel traverse is simply jammed in a door frame. The anchorage eyelet can be used to secure up to 2 individuals simultaneously (when equipped with corresponding PPE equipment). EN 795:2012, B CEN/TS 16415:2013 Simply jammed in a door frame Maximum door width: 1100 mm For 2 individuals (max. 900 mm)

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point (Ø 16 mm) - specially designed for wooden surfaces - is attached to a load-bearing beam and accordingly countered. The anchor can be installed laterally using the angular plate supplied. Our standard package also includes 2 threaded bolts and matching nuts. EN 795:2012, A + CEN/TS 16415:2013 Angular plate for lateral installation 2-hole system for flexible installation For load-bearing wooden structures Minimum beam dimensions: 100 mm x 120 mm Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

The thread of this no-nonsense stainless steel anchorage point (Ø 16 mm) is screwed straight through the wooden panelling into the beam. Simply drill a hole through the panelling (at least 18 mm) and into a load-bearing wooden beam (min. 80 mm x 120 mm). EN 795:2012, A + CEN/TS 16415:2013 Designed for load-bearing wooden structures Minimum beam dimensions: 80 mm x 120 mm Depth of wooden panelling: ≥ 18mm

Request for a quote

ABS SAFETY GMBH

Germany

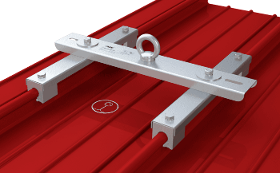

Depending on the subsurface (steel, copper, aluminium or titanium zinc), this stainless steel anchorage point can be installed on a metal roof using either aluminium or brass clamps. It is simply attached to a standing or copper standing seam using the specially-designed clamps supplied - completely penetration-free. EN 795:2012, A + CEN/TS 16415:2013 Freely-rotating anchor eyelet Clamped onto a seam without penetrating your roof surface Mounted on a single seam For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; titanium zinc and aluminium ≥ 0.7 mm For Rheinzink and similar systems Incl. installation set

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ABS SAFETY GMBH

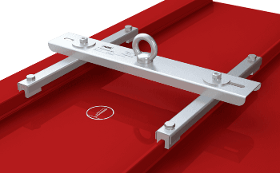

Germany

Attach this stainless steel anchorage point to the rounded-edge seams of a metal roof using the clamps included in the package - completely penetration-free. Your surface only needs to be 0.7mm thick (aluminium) to install it and protect 3 individuals from falls. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm Aluminium thickness ≥ 0.7 mm For BEMO and similar systems Incl. installation set We also supply a protruding model for use in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its robust aluminium clamps, this stainless steel anchorage point can be attached to a metal seam roof with special profiles (KlipTec, Snapfalz etc.) without needing to penetrate the roof surface. The device can be flexibly attached to two seams spaced 300-660 mm apart. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm Sheet thickness ≥ 0.75mm e.g. KlipTec, Snapfalz or similar Incl. installation set We also supply a protruding model for use in a lifeline system

Request for a quote

ABS SAFETY GMBH

Germany

This compact aluminium anchorage point is simply clamped onto a rounded-edge seam - completely penetration-free. Its freely-rotating anchorage eyelet is used to protect 1 individual from falling. As it is so quick and easy to install this anchor, it is ideal as a temporary solution. EN 795:2012, B Clamped design - completely penetration-free Mounted on a single seam Aluminium thickness ≥ 0.7mm e.g. BEMO or similar Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

Our ABS-Lock Falz-H anchorage point (anchor/lifeline system) was specially designed and approved for angled standing seam roof surfaces. This anchor comes with a round base plate which optimally distributes any ensuing force; the base plate itself is equipped with an integrated seal. The sliding properties of the roof are retained even after installation. In Germany: Please observe the installation instructions provided in the "abZ" (national technical approval: Z-14.9-822) EN 795:2012, A + CEN/TS 16415:2017 Designed for standing seam roofs (manufacturer-independent) OSB: Min. 22 mm Wood: Min. 24 mm Can be installed through a vapour barrier / waterproofing Installation set included

Request for a quote

ABS SAFETY GMBH

Germany

You can move freely all around this centrally-installed stainless steel anchorage point. It is equipped with a rotating anchorage eyelet - making it suitable for wall, ground, facade and overhead installation. The 80 mm thread (M16) is firmly cemented into concrete using special adhesive. National technical approval ("abZ"): Z-14.9-688 (max. 2 individuals) (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 (max. 3 individuals) EN 50308:2004 (max. 2 individuals) Freely rotating eyelet Concrete ≥ C20/25 Recommended accessories: Special Adhesive WIT-VM-250 Not suitable for recurrent abseiling usage when installed overhead!

Request for a quote

ABS SAFETY GMBH

Germany

When installed on a steel girder (flange depth 6-26 mm) and accordingly countered, this stainless steel anchor offers workers at heights a freely rotating anchorage eyelet. Simply insert the anchorage point, which is suitable for all directions of load, through a pre-drilled hole and counter using the nut supplied. National technical approval ("abZ"): Z-14.9-688 (pls. observe the installation instructions provided in the "abZ") EN 795:2012, A + CEN/TS 16415:2013 EN 50308:2004 (max. 2 persons) GL-certified 360° rotating eyelet Installation materials included Not suitable for recurrent abseiling usage when installed overhead!

Request for a quote

ABS SAFETY GMBH

Germany

If you are looking for an unobtrusive anchorage point to secure up to 3 individuals, simply attach this stainless steel anchor loop (Ø 5 mm) to a wooden beam. Once installed on a pitched roof, this anchorage device is virtually invisible. All you need for quick-and-easy installation are the 2 stainless steel screws provided. EN 795:2012, A + CEN/TS 16415:2017 Virtually invisible anchorage loop Designed for load-bearing wooden structures The loop is simply screwed onto a wooden rafter (also suitable for over-rafter insulation) Minimum rafter dimensions: 60 mm x 120 mm

Request for a quote

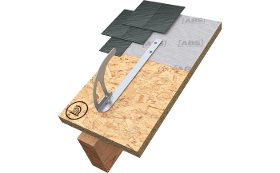

ABS SAFETY GMBH

Germany

This stainless steel, type B roof safety hook for metal seam roofs is suitable for all directions of load (apart from axial loads). It is simply clamped onto a seam without needing to penetrate the roof surface. Our roof hook is installed quickly and easily using the 4 nuts and bolts supplied. Roof safety hook in accordance with EN 517:2006, type B Anchorage point for PPE + ladder hooks For stainless steel ≥ 0.5mm; copper and titanium zinc ≥ 0.6mm; aluminium ≥ 0.7mm Simple, penetration-free installation using just 4 bolts Designed for rounded-edge and standing edge roofs Incl. stainless steel installation set

Request for a quote

ABS SAFETY GMBH

Germany

Thanks to its special base plate, this stainless steel roof safety hook can be flexibly adjusted to fit the angle of your roof surface. The cranked shaft is designed to bridge the battens. It is installed by screwing the 2 stainless steel screws supplied through the counter lathing and into the beam below. Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Designed for load-bearing wooden structures Base plate allows flexible installation Simply screw it onto a wooden beam (also suitable for over-rafter insulation) Min. beam dimensions: 60 mm x 120 mm

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel roof safety hook - specially designed for tiled roofs - is equipped with a cranked shaft for bridging the roof lathing. Is it simply installed by screwing the 2 stainless steel screws supplied through the counter lathing and into the woodem beam. We also supply an optional installation set for flexible attachment to a specially-prepared wooden panel (instead of a beam). This roof hook can be implemented as a natural conducting component in a lightning protection system (100 kA) in accordance with EN 62305-3 Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Designed for load-bearing wooden structures Simply screw it onto a wooden beam (also suitable for over-rafter insulation) Min. beam dimensions: 60 mm x 120 mm Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel roof safety hook with its flat shaft is simply installed on a continuous wooden beam. The 2 stainless steel screws supplied are screwed into the beam through the counter lathing/panelling. Special screws are also available for installing the device on top of over-rafter insulation. This roof hook can be implemented as a natural conducting component in a lightning protection system (100 kA) in accordance with EN 62305-3 Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Designed for load-bearing wooden structures Simply screw it onto a wooden beam (also suitable for over-rafter insulation) Min. beam dimensions: 60 mm x 120 mm Installation materials included

Request for a quote

ABS SAFETY GMBH

Germany

This low-cost, stainless steel roof hook has a cranked shaft - perfect for bridging the roof battens - and is secured in a few easy steps by simply screwing 2 stainless steel screws through the counter battens into the beam below. Roof safety hook in accordance with EN 517:2006, type B Anchorage point + ladder hook Simply screwed onto a wooden beam (min. 60 mm x 120 mm) Incl. installation materials (screw length: 160 mm length, Ø 8 mm)

Request for a quoteResults for

Points - Import exportNumber of results

102 ProductsCompany type

Category

- Nails and tacks (6)

- Locks, bolts and keys (4)

- Cutting - machine tools (3)

- Sharpening - steels and metals (2)

- Electronics - import-export (1)

- Industrial piping (1)

- Bearings, roller (1)

- Components and parts for small household appliances (1)

- Heating, domestic - installations and equipment (1)

- Knives and scissors for household and professional use (1)

- Locks (1)

- Office machines and equipment (1)