- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moulds

Results for

Moulds - Import export

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA UP GELCOAT is an aluminium filled polyester surface resin with a temperature resistance of 110 °C. Pot life is approx. 20 – 30 min. at room temperature, when using 1 – 2 % hardener (art. no. 3150001). The top layer can be polished to high gloss.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The solvent combination contains methyl methacrylate (MMA) and is used for diluting and cleaning.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Release agent H1 (art. no. 9519000) is used to release patterns and moulds. Release agent H1 is applied in a thin coat with a brush or a soft sponge. After the solvent has evaporated, a release film is formed.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA BARRIER COAT is a laminate resin, which is applied to protect the gelcoat for instance with glass fleece (e.g., ALWA MOULD COAT and ALWA UP GELCOAT).

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA EPF 10 is a temperature-resistant, steel-filled gelcoat based on epoxy resin. It is used to produce temperature and abrasion resistant surfaces for vacuum, PU foam, thermionic moulds and heating plates, among others.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA EPT 210 is a laminate and backfilling resin. Laminates can be produced with ALWA EPT 210 in order to manufacture glass fibre plastic parts, gauges, templates, moulds and applications with diverse fillers. ALWA EPT 210 is an epoxy resin that has a low viscosity and a light yellow colour. Under exothermic reaction, it cures in connection with the light yellow hardener H 10 at room temperature. The mixture shows a low viscosity and is particularly appropriate for laminating layers of up to 8 mm. For thicker laminates the application of layers must be interrupted several times in order to avoid too high reaction temperatures in the laminate.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA acryl sealer is used to seal porous surfaces, such as wood, gypsum and rigid foams (not suitable for polystyrene foam). The primer dries in the air and forms a strong film. Apply a thin layer of ALWA acryl sealer evenly with a brush. If 3 % hardener powder is added, the curing process can be reduced to approx. 30 min.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

The mould construction fleece is particularly well tensile and conformable. It is also ideally suitable for complicated parts and moulds. Since this fleece is produced of 100 % polyester fibres, it can be processed with epoxy and polyester resin without any problem. The resin consumption is approx. 1.5 – 2 kg/m² depending on the application. It is ideal for producing free forms.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

225 gr. spin split glass fibre mat as well as 450 gr. emulsion bound glass fibre mat are offered.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Silicone tubes are used for the vacuum channels.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Steel wires are required for the vacuum channels.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Copper pipes are used as heating and cooling coils (very soft and, therefore, easy to bend).

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Aluminium perforated sheets are used in order to reinforce the casting resin moulds.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA release wax (art. no. 9516000) is used to release patterns and moulds. ALWA release wax is applied in a thin coat with a brush or a soft sponge. After the solvent has evaporated, a polishable release film is formed.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA release spray (art. no. 9515000) is used to release patterns and moulds. After the solvent has evaporated, a strong release film is formed. ALWA release spray may not be polished.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA release lacquer (art. no. 9510000) is used to release patterns and moulds. ALWA release lacquer is applied in a thin coat with a brush or a sponge. A thin coat of ALWA release lacquer can also be sprayed on with a conventional spray gun. We recommend to spray on approx. 2 to 3 layers. After approx. 20 min. a strong release film is formed. The drying process can be accelerated by hot air.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Master patterns must be treated with ALWA surface tension remover (art. no. 9500000), so that the ALWA release lacquer does not roll off. ALWA surface tension remover is applied in a thin coat with a brush or a sponge. After approx. 10 min. the solvent is evaporated and ALWA release lacquer can be applied.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA PU foam consists of component A (art. no. 9700005) and component B (art. no. 9701006) and is used, for instance, to produce displacers. The mixing ratio between component A and component B is 1 : 1.2 and the density is approx. 30 kg/m³.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA repair filler (art. no. 5100001) is used in order to repair casting resin moulds. The filler is mixed with 1 – 3 % hardener powder.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD SLV is a universal two-component fast casting PU resin for mould making. It is used for the production of milling devices, negatives, product holders, foundry moulds, mould plates, copy moulds, core boxes, pattern plates, casting moulds, prototype parts, supporting moulds and synthetic cast. It consists of a beige-brown low viscosity resin component A (polyol mixture) and a red-brown, low viscosity hardener (component B) based on isocyanate (Methylendi(phenylisocyanat)e = MDI). Two types are available with different pot life: *ALWA MOULD SLV 3 ~ 3 min. pot life *ALWA MOULD SLV 9 ~ 9 min. pot life

Request for a quote

BORNEMANN GMBH

Germany

Stamp mouldings for embossed or recessed stamping of aluminium or stainless steel sheets for the car industry. We produce the stamp mouldings in accordance with your data in soft or hard condition. Thanks to the high-quality structures, the movement between top and bottom dies is precisely coordinated. The design is based on your drawings or data.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

Our patented material is highly suitable to produce foam moulds and RTM pressure injection moulds. Advantages: • Large volumes of more than 2500 kg can be cast in less than 45 min. • Good castability • Hardly measurable linear shrinkage • High temperature resistance • Demoulding process after approx. 90 min. (after adding the last backfilling compound) • Chemical adhesion to polyester or vinylester gelcoat • Immediately after the first mould half has cooled down, the second mould half can be prepared • Copper pipes keep the mould surface on a nearly constant temperature • Post-curing is not necessary ALWA MOULD D backfilling compounds are the fastest system on the market. For the surface you can chose between two gelcoats: 1) ALWA MOULD COAT This is a vinylester gelcoat that is especially suitable for high-end surfaces. It can be polished to high-gloss. 2) ALWA EPF 10 This is an epoxy gelcoat that is easy-to-use and is recommended for parts, where high-gloss surfaces are not needed

Request for a quote

SPANSET SECUTEX GMBH

Germany

Worm screws, gear wheels, slide rails and other technical mouldings are today made of engineering plastics such as POM (polyoxymethylene), PA (polyamide) or PE (polyethylene). These materials with different property profiles (negative high water absorption with PA, poorer wear behaviour with PE) are supplied as sheets or rods. The required moulded parts are then produced by mechanical processing (turning, milling etc.) in a more or less complex manner. Effective injection moulding is only worthwhile for large quantities together with small component sizes, otherwise the high tool costs cannot be amortized. secutexTechno is characterised by high hardness (70° Shore D) and rigidity over a wide temperature range. It retains its high toughness down to 30 °C, has a high abrasion resistance and a low coefficient of friction. The intrinsic colour is yellow, making it well suited for technical applications. Mechanical processing is simple and comparable with other hard plastics.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We realize with customized plastic moldings. Our product spectrum ranges from the smallest precision parts through housings to complex multi-component parts. On the basis of your sample, your specification or technical drawing, we will create an individual offer and support you during the project. We advise you on the selection of suitable materials and offer cost reduction options. We offer you an active co-operation in the development and construction and give suggestions for improvement. For an offer we need: •technical drawing, sketch or pattern •technical specifications, equipment extras •required amount Please send following informations to: info@nh-technology.de One of our engineering experts will contact you asap.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

We manufacture customer-specific molded parts made of rubber, silicone and elastomer composite parts in small and large series production according to your sample or drawing. Molded rubber parts are generally characterized by their good formability, chemical resistance, pressure and abrasion resistance and good electrical properties. We advise you in detail on the selection of the suitable material, with a view to the functional description, temperature resistance, chemical requirements, weather influences and resilience. Our molded parts are used in all industries, such as the automotive industry, medical technology, mechanical engineering and electronics industry. We offer customized parts: Protective covers for input devices, Rubber seals and rings, Grommets, flanges, bellows, Form Tubes, Rubber damper, PU molded parts (e.g. wheels and rollers) Combined rubber-metal parts / rubber-plastic parts, etc.

Request for a quote

JÄGER-PLASTIK GMBH & CO. KG

Germany

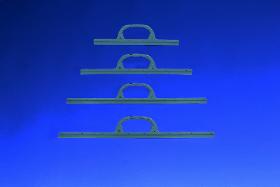

The advantages for you at a glance: with opening assistance on top of the handle U-profile closure reinforced lock button perfectly suitable for insulating and cooling bags standard material: PCR Application areas: Insulating and cooling/thermal bags, recycling carrier bags, reusable packagings, etc.

Request for a quote

JÄGER-PLASTIK GMBH & CO. KG

Germany

The advantages for you at a glance: with opening assistance on top of the handle reinforced design very robust with finger recess for a better hold extremely stable, also for heavy contents perfectly suitable for insulating and cooling bags standard material: PCR Application areas: Insulating and cooling/thermal bags, recycling carrier bags, reusable packagings, etc.

Request for a quote

JÄGER-PLASTIK GMBH & CO. KG

Germany

The advantages for you at a glance: with opening assistance on top of the handle button closure with safety closure perfectly suitable for fruit bags (apples, pears, etc.) standard material: LDPE Application areas: Fruit bags, recycling carrier bags, reusable packagings, etc.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

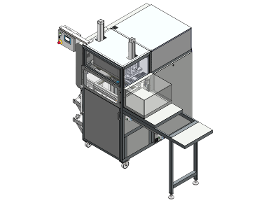

The versatile thermoforming machine for precisely shaped plastic parts

Request for a quoteResults for

Moulds - Import exportNumber of results

39 ProductsCompany type