- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- thinning

Results for

Thinning - Import export

INFICON GMBH

Germany

MAKING EXCELLENCE REPEATABLE Feature-Rich IC6 Provides the Best Measurement Precision Possible The IC6 Thin Film Deposition Controller provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your deposition process. The IC6 uses our ModeLock frequency measurement system to provide stable, high-resolution rate and thickness measurement with an industry-leading rate resolution of 0.00433 Å/s every 1/10 second. No other quartz crystal controller has the performance, quality, and features of the IC6, allowing you to make excellence repeatable. 1 Å for 0 to 9.999 kÅ 10 Å for 10.00 to 99.99 kÅ 100 Å for 100.0 to 999.9 kÅ 1 kÅ for 1000 to 9999 kÅ 0.001 for 0 to 9.999 Å/s if rate filter time setting is 10 seconds or greater 0.01 for 0 to 99.99 Å/s 0.1 for 100 to 999.9 Å/s 100 – 230 V (ac) +/- 15% 50 / 60 Hz +/- 3 Hz (1) Tooling/density = 100/1, fundamental frequency = 6 MHz (2)...

Request for a quote

INFICON GMBH

Germany

SIMPLE OPERATION FOR MANY APPLICATIONS STM-2XM is a two channel rate/thickness monitor that combines high accuracy with flexible programming and easy operation at an affordable price. STM-2XM is equipped with five operation modes to accommodate processes from simple to complex. For example, use simple mode to monitor just one single sensor for the simplest process or use alloy mode for codeposition monitoring. Independent mode allows STM-2XM to function as two completely separate monitors. Two sensor inputs allow for the use of two single or one dual quartz crystal sensor. 10 measurements are taken per second while achieving a resolution of 0.037 Å per measurement (density of 1). FEATURE PACKED STM-2XM has eight programmable digital inputs, eight programmable digital outputs, and four analog outputs allowing for a level of integration usually reserved for more expensive instruments. Programmable features include shutter delay, time/power monitoring, and rate sampling. Use...

Request for a quote

INFICON GMBH

Germany

SMALL IN SIZE AND PRICE, BIG IN PERFORMANCE STM-2 combines the simplicity of USB connectivity with the accuracy of a precision measurement engine, all in a compact, inexpensive package. The size and simplicity of STM-2 help make setup and operation easy and efficient. SUPERIOR PERFORMANCE STM-2 is the most accurate USB powered thin film monitor in the industry. Ten measurements are taken per second while achieving a resolution of 0.037 Å per measurement (density of 1). EASY AND FLEXIBLE INSTALLATION STM-2 comes with everything you need to connect your QCM sensor/feedthrough to a Windows® PC. Simply connect the included BNC cable from the feedthrough to STM-2, then connect the STM-2 to your PC using a standard mini USB cable (included). No external oscillator or power supply is required. STM-2 features an internal oscillator that allows for simple and cost effective installation when STM-2 is located within 1 m (40 in.) of the quartz crystal. A standard INFICON® oscillator...

Request for a quote

INFICON GMBH

Germany

LOW-COST DEPOSITION CONTROL ON A PCI EXPRESS CARD The IQM-233 PCI Express card turns your PC into a thin film deposition controller. This INFICON designed and manufactured product is the ideal choice for system OEMs, or anyone wishing to incorporate a thin film deposition controller into an existing PC or PLC controlled system. Installation is simple—all you need is an unoccupied PCI Express slot. IQM-233 is available to fit in standard or small form factor PC towers. UNPARALLELED FEATURES The IQM-233 features three QCM sensor inputs and three source outputs on each card. Up to two IQM-233 cards can be installed in a single PC (requires optional IQS-233 software), giving you a maximum of six sensor inputs and six source outputs. Only INFICON offers this level of flexibility in a fully integrated PC controlled QCM controller. IQM-233 is compatible with INFICON oscillator IPN 782-900-010, so replacing an SQM-242 card does not require a new oscillator. It is also compatible with...

Request for a quote

INFICON GMBH

Germany

Highly Accurate Sequential or Codeposition Control With advanced electronics, an improved display, and a very affordable price, the INFICON SQC-310 Series gives you features not found on competitors' thin film controllers. And you can choose the ideal model for your application: sequential deposition (SQC-310) or codeposition (SQC-310C).

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INFICON GMBH

Germany

The Best Measurement Precision Possible for OLED Applications Cygnus 2 Thin Film Deposition Controller provides exceptional value by combining the proven performance of INFICON thin film controllers with unique features, all designed for you to achieve the most from your OLED process. Cygnus 2 uses our ModeLock frequency measurement system to provide stable, high-resolution rate and thickness measurement with an industry-leading rate resolution of .00433 Å/s every 1/10 second. No other quartz crystal controller has the performance, quality, and features of Cygnus 2, allowing you to make excellence repeatable. 1 Å for 0 to 9.999 kÅ 10 Å for 10.00 to 99.99 kÅ 100 Å for 100.0 to 999.9 kÅ 1 kÅ for 1000 to 9999 kÅ 0.001 for 0 to 9.999 Å/s 0.01 for 0 to 99.99 Å/s 0.1 for 100 to 999.9 Å/s 100 – 230 V (ac) +/- 15% 50 / 60 Hz +/- 3 Hz (1) Tooling/density = 100/1, fundamental frequency = 6 MHz (2) Varies according to process; figures reflect typical accuracy (3) Maximum configuration of...

Request for a quote

INFICON GMBH

Germany

The SQM-160 uses proven INFICON quartz crystal sensor technology to measure rate and thickness in thin film deposition processes. Two sensor inputs are standard and four additional sensor inputs are optional. Two recorder outputs provide analog rate and thickness signals. Sensor inputs can be assigned to different materials, averaged for accurate deposition control in large systems, or configured for a dual sensor. The rate sampling mode allows a shuttered sensor to extend sensor life in high rate processes. Rate displays of 0.1Å/s or 0.01Å/s are user selectable. In addition, Frequency or Mass displays can be selected. Four relay outputs allow the SQM-160 to control source or sensor shutters, signal time and thickness setpoints, and signal crystal failure. Digital inputs allow external signals to start/stop and zero readings. Standard: RS-232; Optional: USB or Ethernet Standard: RS-232; Optional: USB or Ethernet Class 1 equipment, 73/72/EEC LVD, 89/336/EEC ECD Class 1...

Request for a quote

DURABLE HUNKE & JOCHHEIM GMBH & CO. KG

Germany

Standard scissors for paper and thin fabrics. Dimensions: 6” (15 cm) • Standard scissors for paper and thin textiles • Rust-proof with plastic handles • With rounded tips

Request for a quote

KROHNE MESSTECHNIK GMBH

Germany

The OPTIBAR PC 5060 is a pressure transmitter for process pressure and hydrostatic level measurement in all kinds of process applications. It is designed for absolute and gauge pressure measurement in open tanks and – as dual version for electronic differential pressure measurement – also in closed vessels. The pressure device features a ceramic capacitive measuring cell that guarantees maximum overload and vacuum resistance for high plant availability. The measuring cell can be built into the process absolutely flush and the radially recessed position of the gasket provides additional protection in abrasive media. It is resistant to sudden temperature shocks and can handle operating temperatures of up to +150°C/ +302°F. The OPTIBAR PC 5060 comes with robust plastic and aluminium housing or hygienic stainless steel versions (incl. ingress protection IP69k). The pressure transmitter comes with various diagnostics and digital communication options.

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: highly precise tolerances without surface grinding extremely thin silicone coating layers (in picture: 0.6 mm) high silicone thermal conductivity (in picture: > 0.8 W/mK) anti-adhesive, thin top coatings (in picture: 30µm PFA)

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

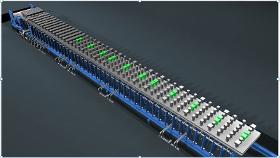

The ultra-thin board package consists of a special cylinder conguration with additional double-acting cylinders. Its concept enables the production of ultra-thin engineered boards in a reliable and stable process. A standard ContiRoll® has a degassing zone in its front section. Double-acting cylinders serve to lift the sides of the press gap to enable a controlled degassing. Since ultra-thin boards are produced at especially high speeds, this standard degassing zone is not long enough for the mat to degas. The optional ultra-thin board package includes additional dierential cylinders functioning as double-acting cylinders to extend the degassing zone signicantly. Dierential cylinders in the remaining part of the press ensure that the upper and the lower steel belts do not make contact during ultra-thin board production, even if there were no mat in-between. Features Additional dierential cylinders operating as double-acting cylinders

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

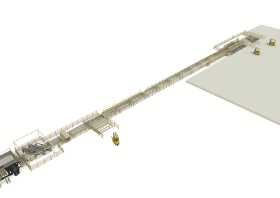

The cooling and stacking line, which is downstream of the ContiRoll®, is the rst part of the nishing line. This is where the continuous process becomes a discontinuous one and the boards are cut from the endless mat. The cooling and stacking line is the rst section of an intralogistical concept that Siempelkamp develops with the customer: We work with the plant owner to dene the best master-board formats that will allow the later end-product formats to be made without ocuts. We develop all downstream processes for the master board and product on the basis of optimum material ows in constant dialogue with the customer. To this end, Siempelkamp sets up a team of experts that will act as the reliable partner throughout the process – from the intralogistical concept, technical implementation, assembly and commissioning/start-up to ongoing support Features and functions Saw section Rejects area Cooling section High-stack forming

Request for a quote

GÖCKE GMBH & CO. KOMMANDITGESELLSCHAFT

Germany

Canted profiles in XXL We cant almost every profile with our special tools. Most of the machines used at Göcke are specially constructed; tools for the sheet metal bending presses as well as stencils for sheet metal blanks are self-produced in-house at Göcke. At Göcke Umformtechnik, every desire of the customer and wish for appointments is turned into reality on modern DNC-controlled sheet metal bending presses. For this, we have available an extensive store depot, even special grades. - Cant profiles up to 21 m - Presses up to 3,000 t

Request for a quoteResults for

Thinning - Import exportNumber of results

14 ProductsCompany type