- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing line

Results for

Processing line - Import export

GSW SCHWABE AG

Germany

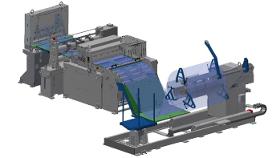

The Combination Slitting & Cut-To-Length Lines are probably the most flexible coil processing lines within the field of cutting. By combining the cutting lengthwise and across, the coil material can be processed into a variety of blanks. So, if your production features a limited number of different coils as basic materials, while the variety of widths and lengths of the blanks is high, a Combination Slitting & Cut-To-Length Line will be the right choice. The system bases on the Cut-To-Length technology while offering the additional functionality of slitting. Since the slitting technology is home-made too, we can provide a fully integrated solution. An incisive experience so to speak. As a sizable advantage, storage space and material costs per ton are both significantly reduced, and with Combination Slitting & Cut-To-Length Lines even smallest batches can be delivered immediately.

Request for a quote

WILH. KÄMPER GMBH U. CO KG

Germany

Processes such as radial riveting or pressing are used to permanently conjoin a metal plate for example with a wire bracket. Test apparatus for monitoring compliance with the required tear values secure the process in line with these safety-relevant components. These assembly parts are used, for example, as reinforcements for backrest frames.

Request for a quote

GSW SCHWABE AG

Germany

Most Winding Lines process one single coil (single-layer winding). There are however also applications where multiple layers are wound: With this process, the rewinding Coil Reel (Rewinder for short) reverses horizontally and orderly puts one layer beside the other, creating one long coil. This will make sense when narrow slit coil materials of small weight and – depending on their thickness – usually short running lengths would require frequent changeovers. Here, a layer-wound coil provides much longer productive time. The “elongation” by the way is done by butt-welding the coil strip ends. We offer this complete technology – including our own end-joining equipment and an adapted servo layering axis for the Rewinder. For thick strips we build vertical straighteners to correct the frequently occurring camber defect.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

This small sized computer controlled deflashing machine can be integrated into the production line easily. This saves temporary storage or extra transports and finally corresponding time loss and costs. The comfortable operator features on newest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network connection (support via internet), recipes memory, user management, logging/documentation/traceability and optional barcode scanner/ID key. Alternatively the E30 is available with quick-exchange basket system. This basket is compatible to our high-pressure washing machine W30 and furthermore optimally suited for a linear in-line-processing →production →deflashing →washing →termpering, as this charge-baskets may be used compatible for each machine. For industry 4.0 demands, the E30 is best prepared. Standardwise, a monitoring of the processing data via network is possible also from an external working place. On option, the control via OPC-UA server is possible.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – s200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for inner applications such as decklid and door inners and other closure inner panels. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Novelis Fusion™ 6HF – e200 is a heat treatable product for applications with extremely demanding formability requirements. This product is recommended for outer applications such as body sides and decklid outers. This product has an excellent balance of properties for forming and strength. In addition, it offers a unique advantage in the hemming process enabling sharp feature lines and rope hem designs that permit the reduction in perceived gap between adjacent panels. All values are typical.

Request for a quote

GSW SCHWABE AG

Germany

Slit metal often has camber. GSW builds Camber Straighteners, that help remove this defect. Coil Feed Lines that process small crosssections often only need minor straightening efforts. Here, we can help with pullthrough Straighteners also known as Flatteners. We usually mount them at the entrance of our Servo Roll Feeds or Air Feeds. Wire materials also often have a coil set – sometimes in two levels even. Single and dual Wire Straighteners help making such bent wires straight again.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Demag components for process cranes turn a crane into a fully fledged process crane, without the need for any additional design or development work. They're fast, safe and reliable, making these components extremely worthwhile elements of the Demag process crane engineering product line. The individual components – MPW open winch units, MPW open winch crabs and corner-bearing end carriages – are proven components that have been tried and tested for many years. They are individually configured to meet the specific requirements of your process crane. The variety of possible applications is virtually unlimited. See all the performance details and benefits on the product pages.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

EXTREMELY GENTLE PROCESSINGRotating barrels offer a cost-effective and technically ideal solution, particularly when processing small parts in medium batches. This helps you get fine surfaces with neatly rounded workpiece edges, thanks also to the relatively long processing times. Trowal rotating barrels are also excellent for fine finishing and polishing. SOPHISTICATED TECHNOLOGY The barrel body is an octagonal, welded, biconal structure. It generates a triple sliding action in the mass of abrasive media with the workpieces to be processed. The lining consists of tear-proof rubber or PU, with the tight-sealing safety cover made of polyurethane. BARREL BODY WITH LIFTING AND LOWERING DEVICE The automatic lifting and lowering device lets you quickly feed and empty the barrel body. This is a major advantage, especially when processing times are short and when you are operating multiple rotating barrels.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible from 0.01 to 24 mm Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions for thicknesses from 0.01 to 24 mm. Precise even on wavy strip With a measuring precision of down to one micrometre per millimetre of strip thickness, they meet the demands of modern rolling mills. Contact gauges adapt to the strip passage and follow any waviness of the material.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

Proven for decades The contact gauges that measure the thickness / width of the strip with an accuracy of a few micrometres are renowned for their outstanding precision and exceptional reliability: Almost 2000 systems that have gone into operation worldwide in recent decades are still in use even today. They still form an integral part of the measurement technology in new plants where the highest precision is demanded. Flexible for up to 9 mm strip thickness / 32 mm strip width Tactile measurement is employed at all stages of the strip production process – on the annealing line and during rolling, on the finishing line or during strip processing as well as in the steel service centre. Vollmer delivers the systems in different versions. Optional the strip thickness gauge can be equipped with an additional strp width measurement unit.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Pipe cleaning systems are designed according to the processing requirements. Here the machine line length changes equivalent to the throughfeed speed. An alkaline cleaning station that adjusts to the individual degree of soiling of the pipe surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line.

Request for a quote

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

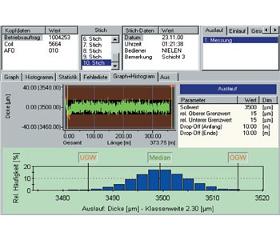

VGraph is the software package for the recording and visualisation of data with extensive statistical data evaluation options. It synchronously records up to 16 measurement values – for example thickness, width and speed of the strip, rolling force or strip tension – on a production line, stores them and evaluates them statistically. With statistical functions such as histograms, Cp and CpK values and error lists, VGraph provides valuable decision aids for the evaluation and further use of the coil produced. The diagnostic instruments allow optimisation of the rolling process and the line engineering. The optional FFT analysis detects periodic fluctuations in the strip thickness. VGraph meets the needs of day-to-day strip production. One example: Random lengths of strip at the leading and trailing ends (drop-off) can be suppressed – even subsequently – in the statistical evaluations.

Request for a quoteResults for

Processing line - Import exportNumber of results

15 ProductsCompany type

Category

- Cars - electrical and electronic parts and components (2)

- Measurement - Equipment & Instruments (2)

- Metal straightening machines (2)

- Rubber - industrial machinery and equipment (2)

- Adjustment - machine tools (1)

- Coil winders (1)

- Cranes and gantries (1)

- Machine tools, metal shaping - parts and accessories (1)

- Metal industrial presses (1)

- SMALL METAL PARTS (1)

- Software (1)

- Software for industry (1)