- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- moving it

Results for

Moving it - Import export

ROLLON GMBH

Germany

“Lift and move” motion profile with multiple stations and long travel lengths. Synchronized movement system with hard anodized profiles. Polyamide nylon wheels with a rack and pinion system manage horizontal and vertical movement. Column modules carry out lifting movement via a recirculating ball screw drive. The column modules are operated with a single geared motor through a transmission with shafts and corner stops. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

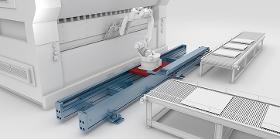

ROLLON GMBH

Germany

Shuttle system for moving robots and heavy loads for long distances with high dynamics. The motion system is available with recirculating ball guides or rollers while the driving system has been designed with rack and pinion. The shuttle is equipped with adjustable ties to achieve alignment even on irregular surfaces. Cable carrier and dampers at the stroke end are included. LOAD CAPACITY ACCORDING TO DYNAMICS Reported data must be verified according to the application. Please get in touch with our technical department for more information.

Request for a quote

IGUS® GMBH

Germany

FTA Floating moving end Compensate parallel errors The igus® compensator for gliding applications with E2/000 and small E4.1 energy chains. At moving arms with strong lateral offset the floating moving end provides for a compensation and therefore for a force-free run of the energy chain in the guide trough. This extends the life time of your application. -Small, light and low priced -Compatible with PPDS basic analysis units -The basic ”floating moving end“ can be used with the following chain series: 2500, 2700, 3500, E4.28, E4.32 and E4.42 Max. travel distance:100m Max. acceleration: up zo 50m = 2 m/s 2 | 50-100m = 1 m/s 2

Request for a quote

GSW SCHWABE AG

Germany

Moving solutions for all who need to transport or lift an object but have no fork lift or crane available Our Lift Trolleys, Lift Tables and Box Tilters will not let you down.

Request for a quote

GSW SCHWABE AG

Germany

A stationary production aid everywhere where bigger loads have to be lifted or lowered, e.g. as loading table behind compact feed lines Stroke from 800 1600 mm Electrohydraulically driven lifting and lowering, controlled via hand sensor device (Totmann) on a 3m cable.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

MOVE cutlery inserts feature simple no-frills linework and square shapes. The combination of fixed elements and movable dividers within the multi-purpose compartments complements the design and introduces greater flexibility to the organization of kitchen drawers. Modern vacuum thermoforming and tool technology make it possible to control the flow of material in the production process to such an extent that a good material distribution is achieved even when handling highly stretched surfaces. The new styling devoid of radii and graduations harmoniously adapts itself to the design of the drawer guidance systems. As one has come to expect from AGOFORM, every carcase size has its own divisions and variants from 300mm to 1200mm width in two different depths. A sturdy construction coupled with hygienic polystyrene makes for a durable, easy-clean product of the highest quality.

Request for a quote

AGOFORM GMBH AUGUST OTTENSMEYER

Germany

MOVE cutlery inserts feature simple no-frills linework and square shapes. The combination of fixed elements and movable dividers within the multi-purpose compartments complements the design and introduces greater flexibility to the organization of kitchen drawers. Modern vacuum thermoforming and tool technology make it possible to control the flow of material in the production process to such an extent that a good material distribution is achieved even when handling highly stretched surfaces. The new styling devoid of radii and graduations harmoniously adapts itself to the design of the drawer guidance systems. As one has come to expect from AGOFORM, every carcase size has its own divisions and variants from 300mm to 1200mm width in two different depths. A sturdy construction coupled with hygienic polystyrene makes for a durable, easy-clean product of the highest quality.

Request for a quote

MIXACO MASCHINENBAU

Germany

MIXACO Container-Mover The container mover enables simple and quick transportation. You will also receive a battery charger in the scope of delivery. The advantages at a glance •Forward and backward movements of the container that do not strain the head due to heavy-duty electric drive •Simple handling •Handle with height adjustment •Adjustable speed •Self-engaging coupling for quick coupling and decoupling without tools

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Frequently, a production run starts or ends with the automatic feeding or removal of workpieces. Our feeders and stackers are produced in various capacity levels, with vacuum suction traverses, with or without pit. The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

Venjakob/Nutro offers a wide spectrum of material handling systems, from simple, manual systems to fully automatic "non-contact" operation. Venjakob/Nutro is able to provide customer-specific constructions for automatic feeding and delivery as well as integrate transport devices or material handling robots in the spraying plant. The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

There are often several possibilities to realise automatic accumulation or separation of workpieces in a production process. Venjakob optimises workpiece handling in a customised approach. This picture shows how a drying zone can be shortened by the use of vertical workpiece guidance. Vertical buffer zones are often planned to obtain free movement areas for the production line. The VEN MOVE system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

At the time of workpiece transfer, a change is made from longitudinal transport to crosswise transport. In contrast to curve conveyors, angular transfer systems operate in cycles. Depending on the requirement, they can be planned as collecting or separating device. Possible configurations include 90° or 180° belt, chain or rake cross conveyors. A rake or crank rocker linkage or an electro-pneumatic control can be used to transfer workpieces from lenthwise to crosswise or vice versa. The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The processing of both faces of a workpiece requires a professional turning solution. The turning process (Fig. 1) with lane change shown, achieves a very high turning capacity while simultaneously safeguarding the quality of the parts to be processed. Workpiece processing often requires turning from longitudinal to cross and vice versa. A cone and crank rocker linkage represent a simple and safe possibility to turn workpieces. (Fig. 3) The VEN BRUSH system equipment Solutions possible with the VEN MOVE series cover several functions such as rotating, turning, transferring, stacking, feeding, accumulation, separation or allocation.

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

PowerFlex is designed to be a robust, flexible and reliable conveyor solution for almost any operation requirement. Using its integrated handles and intuitive design, the conveyor can be contorted and shaped to fit into infinite environments. Its braked castors, 240v power supply and renowned latching connections make it an incredibly userfriendly piece of equipment. The PowerFlex SmartFlow platform differs from traditional PowerFlex with its distinct controls functionality. SmartFlow allows for multiple flow control options within one conveyor. Different user operations call for different equipment functionality – SmartFlow puts them all in one place. The selector switch is mounted on the unit’s selfcontained control box, which allows you to switch from 5 varying flow control modes. See below for further details. PFSF also retains all PowerFlex’s renowned functionality – simply connect multiple SmartFlow units to create whatever length is required.

Request for a quoteResults for

Moving it - Import exportNumber of results

15 ProductsCompany type