- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling design

Results for

Milling design - Import export

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

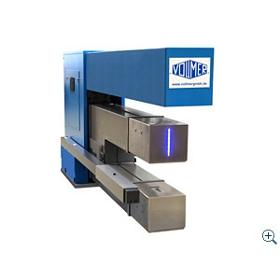

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Sophisticated drive concepts for ball mills and rotary kilns require powerful solutions. Eickhoff offers different gear solutions for the various drive concepts established in the field, such as side drive, central drive and direct drive. In addition to the robust Eickhoff helical gearboxes, our ED planetary gearboxes are preferred, especially for a central drive. They offer a compact solution with extremely high power density and are therefore also leading from an economic point of view. Even torques of over 7,000 kNm can be realised. Typical applications are the crushing of raw materials as well as the burning of cement clinker. The gears are characterised by a long service life and high power density.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Milling design - Import exportNumber of results

3 ProductsCompany type