- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- milling design

Results for

Milling design - Import export

ROCHOLL GMBH

Germany

We love a challenge so we are more than happy to take on special designs. We translate your specifications into top-quality products. In order to meet the most stringent requirements, we rely on our comprehensive machine park and on the production facilities run by highly specialized partner companies. These machines have been designed to manufacture both individual items and batches without any problems. Would you like to have more detailed information on our special designs? Why not contact us directly? We will be happy to assist you. Milling of profiles Special concrete designs Rings for placing Shore test specimens Milling of dumbbell test specimens for tensile tests Multiple test specimens according to DIN 53281ff Stainless steel rings for tests according to EN ISO 10563 Spacers for standard joints according to ISO 11600 Spacers for elongation test according to ISO 11600, made of aluminum or PMMA in various % values Feed mechanisms

Request for a quote

FRIEDRICH AUGUST PICARD GMBH & CO. KG

Germany

The contact wheel FAPI-VU MILLED is the addition to the smooth model. This is accomplished by milling grooves into the coating of lamellae of foamed up Vulkollan®. The overall height of the coating is also adapted to the respective application and is therefore variable. The grooves can be cut into the coating in various widths, depths and angles. Due to the grooves inserted, contact discs with a milled design are significantly more aggressive than contact discs with a smooth design. The aggressiveness effect of the contact disk can be optimized for each application through an optimal groove width-groove depth-web width ratio so that high-performance processes are possible. With this contact disc, too, no signs of fatigue occur after long, intensive use if used properly.The contact discs of the FAPI-VU series are exclusively provided with a coating made of foamed Vulkollan®. We will be happy to advise you in order to find a suitable contact wheel for you.

Request for a quote

EGE-ELEKTRONIK SPEZIAL-SENSOREN GMBH

Germany

EGE capacitive sensors for use down to -230°C reliably detect deep-frozen liquid gases or granulates for cryogenic grinding, for example. The sensors are based on the proven capacitive principle. The measuring element of the sensor designed as a cylindrical capacitor. The medium to be detected functions as dielectric. The medium in touch with the sensor generates a capacity change. This is converted into a switching signal or an analogue 4...20 mA output signal. This applies both to conductive and on-conductive media. The sensors reliably record super-cooled liquid gases or granulate, for example for cryogenic milling. With their compact design the sensors of this series are well suited for installation in tight spaces.

Request for a quote

STARRAG GMBH

Germany

Flexibility, efficiency and precision play a very important role for machine manufacturers and tool builders, especially when dealing with large components. These three requirements led to the development of the gantry machining centre TS/TFS NEO with a fixed and movable crossbeam, whereby the customer chooses the table designs, controls and milling units suitable for them on a modular basis. The TS/TFS NEO features a new milling unit and a modified Caxis (±400°) which, thanks to its enormous flexibility, can be used for efficient production of highly precise machine parts. The large number of automatically changeable milling heads increases the machine's flexibility within its scope of application. The TFS also allows automatic tool or spindle changing and tool or workpiece measurement.

Request for a quote

HAACON HEBETECHNIK GMBH

Germany

haacon hebetechnik gmbh expands its standard range to include rack and pinion winches with fastening lugs for wall mounting. The serial drive type is a spring-loaded safety crank (SiFeKu), which holds the load in any desired position under tensile and compressive loading. The winch can be utilised in any position. The winches are produced in three load classes: 1.5 t 3 t 5 t. The robust design with milled gear rack and hardened gear components is suitable for use in harsh applications. The crank handle can be moved for space efficiency. Special designs with other rack and pinion lengths, detachable crank design, assembled fastening options can be supplied at short notice.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

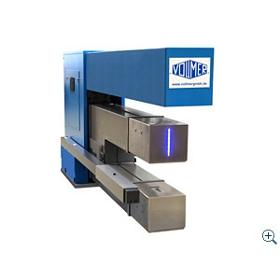

FRIEDRICH VOLLMER FEINMESSGERÄTEBAU GMBH

Germany

The new standard for precision and speed With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness. VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers. As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Request for a quote

F. ZIMMERMANN GMBH

Germany

The portal milling machine FZ40 compact is designed for the machining of hard materials as well as aluminum. The inherently rigid machine structure allows for simultaneous 5-axis high speed machining. This compact machine, with its solid cast base does not require a foundation. The machine table is integrated into the cast baseplate, which allows up to 16 metric tons of table load. Eight mounting elements of the FZ40 compact reduce vibration – the basic requirement for high accuracy and optimum surface quality. The sidewalls are filled with a special dampening concrete mix to further enhance performance. The machine has a fully enclosed working space with a fixed machine table. The structural sound overhead gantry with a reinforced Z-ram make up the moving masses. By adding our new dynamic milling head VH60, Zimmermann has created a powerful performer. The combination of high strength and rigidity, constant moving masses and dynamic drives, will meet the industries high demands.

Request for a quote

EICKHOFF ANTRIEBSTECHNIK GMBH

Germany

Sophisticated drive concepts for ball mills and rotary kilns require powerful solutions. Eickhoff offers different gear solutions for the various drive concepts established in the field, such as side drive, central drive and direct drive. In addition to the robust Eickhoff helical gearboxes, our ED planetary gearboxes are preferred, especially for a central drive. They offer a compact solution with extremely high power density and are therefore also leading from an economic point of view. Even torques of over 7,000 kNm can be realised. Typical applications are the crushing of raw materials as well as the burning of cement clinker. The gears are characterised by a long service life and high power density.

Request for a quoteResults for

Milling design - Import exportNumber of results

9 ProductsCountries

Company type