- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- complete plants

Results for

Complete plants - Import export

TECHNOTRANS SOLUTIONS GMBH

Germany

A complete centralised cooling plant, including the required peripherals, can be set up in the absolute shortest possible time at the subsequent place of installation and is immediately ready for use by means of prefabrication and installation in a container. This way, the otherwise high investments for an operating building, the costs for installation and start-up of the plant are reduced. Container cooling plants almost have no limitations in terms of their capacity and variety of possible combinations. They are supplemented by peripheral systems such as water treatment and water preparation systems or compressed air compressors. A series of different cooling systems and the combined systems composed of these units are primarily available: Chiller Heat pump systems for heat recovery Cooling tower combined with a KU system as a closed, clean cooling circuit Air heaters for direct recovery of heat hermeticool-units hermeticool hybrid-units

Request for a quote

CERTUSS DAMPFAUTOMATEN GMBH & CO. KG

Germany

Our steam generators are available on request as a ready-to-operate steam boiler plant: CERTUSS steam generator plus CERTUSS supply unit CVE. All components for the water supply and water conditioning of the CERTUSS steam generator are included in the complete steam plant. - Feed water tank - Desalination heat exchanger - Water softening equipment - Test extraction cooler - Mixing heat exchanger - Measuring equipment - Steam dryer The CVE supply unit is compatible with all the CERTUSS steam generators. In addition to the CERTUSS supply unit as a ready-to-operate boiler house installation on a basic frame, we also offer a complete container installation on request. Depending on the desired steam output a multiple steam boiler plant may be suitable for you.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

CONEC ELEKTRONISCHE BAUELEMENTE GMBH

Germany

Adopting Ethernet standards from the office environment into the industrial world has opened up new perspectives for automation technology. From control level via factory networking to field level, communication has to be provided with high transmission rates and in real time in order to enable remote maintenance and control of complete plants and systems via networks. However, the precondition is robust and high-quality connection technology.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

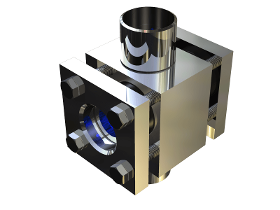

High pressure flow sight glasses Type 521 Use: For observation of filling and flow in piping. The Sight Glass enables a reliable survey of function and performance of single devices and complete plants.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

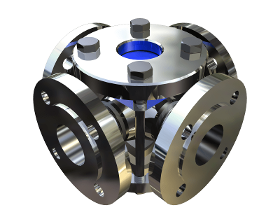

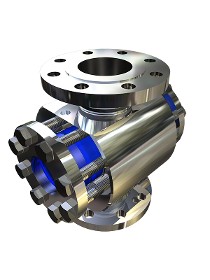

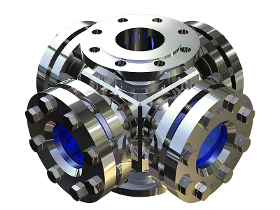

Four way sight glass Type 595 with Flanged Connections Use: Visual Checking of Filling and Flows in Piping. Sight Glasses allow for reliable Observation of Function and Performance in single devices or complete plants.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

High pressure flow sight glasses Type 520, flanged PN 63, PN100 or PN160 Use: For observation of filling and flow in piping. The Sight Glass enables a reliable survey of function and performance of single devices and complete plants.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

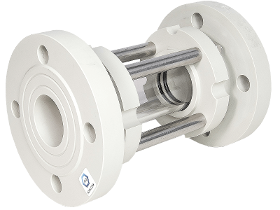

Tubular sight glasses Type 620-K (plastic) with flange connections Use: Tubular sight glasses built from PVC, PP und PVDF Are used for visual checking and control of flows and filling in pipes. The sight glasses allow a reliable observation of function and performance in single devices and complete plants. Tubular sight glasses offer a barrier-free cross section with no significant dead space.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flow sight glasses type 596- with four Viewports Use: Visual Checking of Filling and Flows in Piping. Sight Glasses allow for reliable Observation of Function and Performance in single devices or complete plants. Type 596 allows observation from four sides without sacrificing stability. In this designe it is possible to use one or two sides as a measuring Point.

Request for a quote

FRIMO GROUP GMBH

Germany

Flexible and individual solutions FRIMO offers many different solutions in terms of combining tool carriers, mix and metering units, and the peripheral equipment necessary to complete production plants. Individual and turnkey production solutions are therefore highly available.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

High-pressure sight glass type 521 with weld ends Use: Visual survey of flow and filling processes in piping. The sight glasses allow for a reliable observation of function and performance of single devices or complete plants. With this design, no significant amount of liquid will remain in the sight glass when installed horizontally. With standard sight glasses, liquid will remain in the sight glass body. This liquid will drain out with this design.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flow Sight Glass Type 531 with welding connections Verwendung: Visual survey of flow and filling processes in piping. The sight glasses allow for a reliable observation of function and performance of single devices or complete plants. With this design, no significant amount of liquid will remain in the sight glass when installed horizontally. With standard sight glasses, liquid will remain in the sight glass body. This liquid will drain out with this design.

Request for a quote

ACI INDUSTRIEARMATUREN GMBH

Germany

Flow sight glasses type 530 - PN16-40 designed as welded construction Use: Visual survey of flow and filling processes in piping. The sight glasses allow for a reliable observation of function and performance of single devices or complete plants. With this design, no significant amount of liquid will remain in the sight glass when installed horizontally. With standard sight glasses, liquid will remain in the sight glass body. This liquid will drain out with this design.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The PALLMANN rener system produces high quality bers from chips, saw dust, shavings, and annual plants for MDF, HDF, and insulation board production. PALLMANN supplies complete plants consisting of perfectly coordinated components to ensure the highest ber quality with minimal energy input. High quality ber production for MDF, HDF and insulation board plants with PALLMANN rening systems Chip bin for pre-steaming of chips: The closed design of the bin with downward tapering base is equipped with vibrating motors to ensure a continuous discharge. Circular steam injection results in perfect pre-tempering of the chips. Integrated load cells allow the online presentation of the lling level of the chips inside the bin. Plug screw: The extremely heavy and robust plug screw feeds the chips reliably into the digester and squeezes out excess water by doing so. The position compensation, caused by the thermal expansion of the digester

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Assembly of plant components and machines We assemble plant components and complete machines including electrical wiring, pneumatics and hydraulics in our factory buildings. Our 55 specialists in the assembly departments are waiting for your challenge. Key features own production of large diameter pipelines Performance of surface coatings Complete systems or components Series or individual assembly Electric, pneumatic and hydraulic function test on test bench Advantages all from one supplier installation-ready dispatch Handling of large components up to 400t total weight Factory commissioning personal contacts

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Complete plants - Import exportNumber of results

18 ProductsCompany type