- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cleaning- industrial

Results for

Cleaning- industrial - Import export

WOMA GMBH

Germany

With up to 95°C façades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The compact and light singleaxle trailer can be brought to site with almost any middle class car. The easy to understand WOMATIC 4Control with operational status monitoring, pressurerpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption. The tank system with 5 chambers including a safety trough hinders operational fluids escaping, such as fuel, oil or softeners.

Request for a quote

WOMA GMBH

Germany

With up to 95 °C façades, small pipes, industrial flooring and other surfaces can be easily cleaned, oil and grease can be washed away and coating can be removed. The compact and light singleaxle trailer can be brought to site with almost any middle class car. The easy to understand WOMATIC 4Control with operational status monitoring, pressurerpm regulation and pressureless circulation ensures high operational safety, low wear and tear, long service life, and last but not least, minimal fuel consumption. The tank system with 5 chambers including a safety trough hinders operational fluids escaping, such as fuel, oil or softeners.

Request for a quote

JETCLEAN GMBH

Germany

The complexity of hydraulic systems is continually increasing. As a result, the purity of the installed components is becoming more and more significant. This applies not only to pumps and valves, but also to the pressure lines that connect them. The ptcsystem® is easy to handle. It provides effective protection against initial damage and premature component wear. Compressed air at a pressure of 6-8 bar is used to route a cleaning projectile through the lines needing to be cleaned. The cleaning of complex bending geometries is possible. The chrome-plated launcher made of high-strength aluminium is an extremely durable tool, even under the toughest working conditions. Using a balancer, it can be hung up such that it is always ready to hand. With its ergonomically designed handle and rotatable compressed air connection, the ptcsystem® launcher is also suitable for cleaning small product series.

Request for a quote

JETCLEAN GMBH

Germany

The FERRET pipe cleaning machine is a user-friendly and handy tool for cleaning horizontal and vertical flue gas pipes. This eliminates the need for strenuous cleaning with brushes on a rod or awkward fiddling with rotating shafts. This significantly reduces the cleaning time. The FERRET machine is driven pneumatically. The oscillating brush propels the machine forward automatically and ensures an excellent cleaning result. Air consumption is low. A work area of approx. 0.5 m in front of the boiler is more than sufficient. Use the FERRET machine to clean your flue gas pipes up to a residual temperature of 150 °C. The use of special vacuum cleaner nozzles means that work is carried out virtually dust-free.

Request for a quote

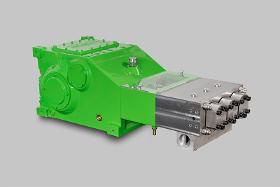

KAMAT GMBH & CO. KG

Germany

The K18000-3G triplex plunger pump has forced lubrication, making it ideal for continuous operation. Its main application is industrial cleaning. For large ship areas it is advisable to combine the pump with the Magnet Crawler (Ship Hull Crawler) from the Gekko range. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature. - Minimum inlet pressures dependent on fluid being pumped - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Forced lubrication gearbox (> 130 kW with oil cooler) - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Can also be operated vertically - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request

Request for a quote

WOMA GMBH

Germany

The highpressure pumps of the Z series deliver operating pressures up to 1,500 bar. With a high number of pressure and nominal flow rate combinations, the pumps are preferably used in industrial cleaning, paint stripping and also in descaling.For pumps with an operating pressure of more than 1,000 bar, hard metal plungers are used, which are particularly stable in order to guarantee a long service life and thus low maintenance costs.

Request for a quote

PFLITSCH GMBH & CO. KG

Germany

The blueglobe CLEAN Plus is the first cable gland to be certified to the high EHEDG standard and therefore can be used without risk in the food, pharmaceutical and chemical industries and in clean room technology applications. BGN also confirmed conformity of this cable gland with the relevant applicable testing specifications in test certificate NV 13132. The cable gland blueglobe CLEAN Plus has no cavities, gaps or external threads but has a smooth surface (roughness Ra < 0.8 μm) and rounded surfaces in contact with the wrench. PFLITSCH uses high-grade stainless steel 1.4404/AISI 316L to manufacture this product. All seals are made from plastics that comply with FDA 21 CFR §177.2600 and are suitable for being in contact with food.

Request for a quote

FRIMO GROUP GMBH

Germany

Ideal for trimming or scoring foils and skins Blade cutting is a very fast, precise and clean process. In the automotive industry, it is particularly well suited for kiss cutting, edge cutting and for cutting notches in foils and leather skins to prepare for edge folding processes. A special form of blade cutting is scoring, i.e. the intentional weakening of leather, plastic foils and form skins to create specific tear lines, such as to allow the release of airbags. Ultrasonic cutting technology allows for even more possibilities in die and kiss cutting for foamed components with appropriate material combinations. This technology allows parts to be cut dust and chip free with a very low noise level.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-pressure cleaning and surface preparation with water requires precise management of the water jet. This precise management is necessary to ensure that the required result (e.g. surface finish) is achieved within a reasonable time. The method must be safe and fatigue free. With this in mind, we offer a specially designed and manufactured range of high pressure guns with electrical or mechanical control. The exceptional ergonomics of these tools have been achieved through innovative detail solutions: For example, our high-pressure guns are equipped with a special swivel handle that transmits any torque to the wrist. In addition, the hose connection can be swivelled in all directions, allowing optimum hose routing for all working situations. Our range of high pressure guns is complemented by various versions of foot valves, rotating gun lances, rotating nozzles and other accessories for a wide variety of applications, such as pipe cleaning.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Performance in a small space Our compact K100-3 high-pressure three-plunger pump boasts impressive performance data: With only 15 kW of input power, it delivers a pressure of 2000 bar, making it one of the most powerful pumps in its size class. The K100-3 triplex plunger pump really comes into its own when it comes to water jetting for industrial high-pressure cleaning.

Request for a quote

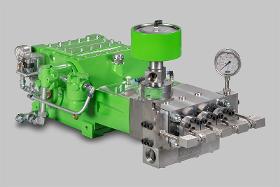

KAMAT GMBH & CO. KG

Germany

With 110 kW, the K11000-3G high-pressure pump is a powerful plunger pump that is mostly used in intermittent operation. The reason for this is that this KAMAT high pressure pump has splash lubrication and not oil pressure lubrication. This makes the pump more suitable for intermittent operation, but it is extremely robust and can therefore be used in continuous operation even at 110 kW. Classic applications for this pump are industrial cleaning, blasting and process engineering. SPECIAL FEATURES - Capacity data at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Dynamically balanced gearbox - Splash lubricated gearbox - Standard gear ratios i = 3,00 - 3,14 - 3,39 - 3,76 - 4,13 - 4,50 - 4,93 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils etc. on request, oils etc. on request

Request for a quote

KAMAT GMBH & CO. KG

Germany

KAMAT's K4500-3 three-plunger high-pressure pump is a powerful pump that is ideal for a wide range of industrial cleaning applications, water steel cutting, pressure testing, surface removal and machining. Modularity for customisation, also as a process pump With an output of 45 kW, the K4500-3 is the entry-level model in the proven KAMAT modular system. The modular design not only allows the use of different pump heads, but also adaptation to different operating pressures and pumped media. As a process pump, it can even handle fluids with viscosities up to 2000 mPas. SPECIAL FEATURES - Flow rate data at 100% volumetric efficiency - and 20°C ambient temperature - Minimum inlet pressures depending on pumped liquid - Speed range 10-100% depending on rod force - Gearbox with splash lubrication - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc.

Request for a quote

KAMAT GMBH & CO. KG

Germany

Versatile, turnkey diesel high-pressure pumping units Special applications require customised high-pressure systems, which KAMAT can provide from the initial project idea through to turnkey installation, with 100% of the manufacture taking place in-house. Depending on the application, our customers can choose from a range of drives, power transmission components, PLC controls, measuring systems, data transmission, remote controls, pneumatic and electric valve controls, chassis and sound insulation. However, the units are ready for use on the base frame on which they are delivered. KAMAT diesel-powered units are traditionally used in industrial cleaning and pressure testing, mining and water hydraulics, but special solutions for special fluids or to meet explosion protection requirements are also part of the KAMAT range. It makes no difference whether the customer requires a mobile or stationary unit.

Request for a quote

KAMAT GMBH & CO. KG

Germany

High-Pressure Cleaning, Load Change Systems and Pressure Test Systems If your application requires forced lubrication and an oil cooler may be required, the powerful K9000-3G three-plunger high-pressure pump is an alternative to the smaller K8000-3G three-plunger high-pressure pump. Like the compact K8000 model, this 90 kW high-pressure pump is suitable for smaller industrial applications such as industrial cleaning, jetting or process engineering. SPECIAL FEATURES - Capacities at 100% volumetric efficiency and 20°C ambient temperature - Minimum inlet pressures depending on fluid - Speed range 10-100% depending on rod force - Forced lubrication gearbox (> 75 kW with oil cooler) - Standard gear ratios i = 2.75 - 3.22 - 3.68 - Also available to API 674 - Special fluids such as seawater, glycol, methanol, oils, etc. on request - Vertical operation possible

Request for a quote

CBG COMPOSITES GMBH

Germany

Our care products specially developed for Plexiglas help you to maintain the beauty and value of the material for years and decades. In comparison to silicate glass, two properties must be taken into particular consideration when caring for and cleaning acrylic glass. On the one hand the lower surface hardness and therefore higher susceptibility to scratches of acrylic glass, on the other hand the susceptibility of acrylic glass to solvents, especially organic ones. The use of incompatible polishing materials can cause stress cracks and matt surfaces. With fakopol® a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics. It has both cleaning and polishing action, removes wipe scratches and marks and is ideal for finishing of industrially manufactured parts. Gives long-lasting protection and glossy deep shine. The treatment process is quite simple.

Request for a quote

CBG COMPOSITES GMBH

Germany

With fako® Polishing paste No.9311 a care product is available, which is specially developed for the properties of Plexiglas, other acrylic glass and plastics. Polishes deep scratches and scrapes. Matt surfaces become clear again, scratches and scrapes are removed. Unsightly panes become flawless again! The treatment process is quite simple. Clean dirty surfaces with clear lukewarm water and a clean, soft viscose sponge until adhering dirt is removed. Put some fako® Polishing paste No. 9311 with lint-free fako® special polishing cloth on the moistened surface and polish under pressure in circular movements until the surface is dry. Polish to a gloss with another dry fako® special polishing cloth until the residues are removed and the surface is dry and clear. When removing deep scratches, the polishing process may cause matt spots. In this case we recommend an after-treatment with fako® Polishing milk No.9322.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Frontloader Series The PERKUTE parts cleaning machines from the Frontloader series are specially conceived for the simple and effective cleaning and de-greasing of both, high-volume components as well as heavy components, as well as those with complex and sensitive geometries. The workpieces are loaded through crane charging or with loading trolleys or loading ramps onto the product slide and then into the washing system. The stainless steel frontloader washing machines with their space-saving, compact design, either work with a driven rotating basket or in the case of sensitive parts, with a nozzle pipe system transported by means of a double-chain, with the products being at rest. All the process stages like washing, rinsing (not in the case of the FR Series) and drying take place in the same treatment chamber. A large number of options for preparing the process media leaves almost nothing to be desired.

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Industrial parts cleaning with the Perkute Toploader Series The PERKUTE rotating basket cleaning machine from the Toploader series is used wherever effective and inexpensive cleaning of parts of any kind is necessary. The rotating basket, designed for large weights, is powered by means of a low-wear friction wheel drive and the aqueous cleaning in the spray process takes place by means of a nozzle pipe system with special flat-spray nozzles that is arranged on 3 sides. A powerful washing pump supplies the system with the necessary pressure and volume flow. The parts cleaning machines, made completely of non-rusting special steel, istinguish themselves by their compact and robust construction as well as simple handling. They are mobile to deploy and designed to be space-saving. Customisation for individual cleaning tasks can be optimised through a comprehensive range of accessories.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

PARTS CLEANING FOR REPAIR AND MAINTENANCEImportant components require thorough and regular cleaning and maintenance, especially in industry, mechanical engineering and the automotive sector. Our TRT 83 x 37 cleaning trough removes grease, lubricants and other residues thoroughly and reliably, before the components are reinstalled. WHICH WORKPIECES CAN BE CLEANED? You can use the TRT 83 x 37 cleaning trough to effortlessly clean workpieces measuring up to 80 cm in length and 30 cm in diameter. Here are some examples: Bearing shells and covers Engine components Gearbox components Shafts and axles Labyrinth rings Bearings, bearing units and bearing housings

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

Individuality and problem-solving are our strengths The PERKUTE system offers solution for every requirement in industrial cleaning technology. Many special solutions could be developed because of the wide product range. We have compiled some reference examples of already implemented special solutions. Special Solutions/ application examples Conveyor machine TW 103 with handling equipment "For cleaning closing thrustor in time of the machine center" Conveyor machine TW 108 with return transport passage "Cleaning of synthetic material boxes" Dip facility TL - 70T "Cleaning of valve cases" Conveyor machine TW 101 with feed system and delivery "Cleaning of hollows" Spraying cleaning facility FR-130H "Cleaning of goods carrier" Spraying cleaning facility FR-90H "Cleaning of store cages in bulk baskets" Spraying cleaning facility RC 82 "Cleaning of drawing dies with with 100 bar"

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

A solid single-chamber parts cleaner for automatic water based spray cleaning. This series is extendable by varies extras which can be retrofitted. The RC-machine is a low costs entry to the modern world of industrial parts cleaning. The PERKUTE-system: economically - environmental – effektive Basic equipment Compact and sturdy construction Made of stainless steel Simple operation Space-saving 3D-blast pipe system incl. fan nozzles Low water pressure switch as dry-run protection Suction filter made of stainless steel front of the pump Adapter for steam extraction Basket drive by water pressure (RC 68, RC 82) Electronic basket drive (RC 122, RC 162) Preparation for electronic basket drive (RC 82) 2“ socket slide vlave for the tank emptying Safety limit switch at cover

Request for a quote

FILTEC W. HERMANNS GMBH

Germany

EMMITEX® sewing threads set standards in the manufacture of technical textiles as well as outdoor and architectural textiles. In particular, they are used in filter media for industrial gas cleaning and solid/liquid separation. They are durable, tensile, temperature and absolutely UV resistant and are resistant to alkalis, acids and oxidizing agents. Preferred applications are the production of: - Filter media for industrial gas cleaning (for example as filter tubes and filter bags) - Filter media for solid/liquid separation (for example as disc filters, belt filters, filter press cloths) - Outdoor textiles (for example as awnings, sun protection fabrics) - Architectural textiles

Request for a quote

FILTEC W. HERMANNS GMBH

Germany

EMMITEX® sewing threads set standards in the manufacture of technical textiles as well as outdoor and architectural textiles. In particular, they are used in filter media for industrial gas cleaning and solid/liquid separation. They are durable, tensile, temperature and absolutely UV resistant and are resistant to alkalis, acids and oxidizing agents. Preferred applications are the production of: - Filter media for industrial gas cleaning (for example as filter tubes and filter bags) - Filter media for solid/liquid separation (for example as disc filters, belt filters, filter press cloths) - Outdoor textiles (for example as awnings, sun protection fabrics) - Architectural textiles

Request for a quote

FILTEC W. HERMANNS GMBH

Germany

EMMITEX® sewing threads set standards in the manufacture of technical textiles as well as outdoor and architectural textiles. In particular, they are used in filter media for industrial gas cleaning and solid/liquid separation. They are durable, tensile, temperature and absolutely UV resistant and are resistant to alkalis, acids and oxidizing agents. Preferred applications are the production of: - Filter media for industrial gas cleaning (for example as filter tubes and filter bags) - Filter media for solid/liquid separation (for example as disc filters, belt filters, filter press cloths) - Outdoor textiles (for example as awnings, sun protection fabrics) - Architectural textiles

Request for a quoteResults for

Cleaning- industrial - Import exportNumber of results

26 ProductsCompany type

Category

- Cleaning machines, industrial (6)

- Pumps (5)

- Cleaning, industrial (4)

- Cleaning and maintenance products, industrial (3)

- Threads and yarns, artificial and synthetic (3)

- Cleaning and maintenance - equipment and supplies (1)

- Adjustment - machine tools (1)

- Electric and electronic components - machines for manufacturing (1)

- Industrial cabling (1)

- Piston pumps (1)

- Pumps, hydraulic (1)