- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machine modernization

Results for

Machine modernization - Import export

GSW SCHWABE AG

Germany

Coil Cradles are made to help unwind coils in rough production environments. Mostly combined with a straightening unit, they work with narrow and thick materials. Built to last, Coil Cradles offer quite a few advantages Simple handling of even hightensile materials with strong clockspring, short setup times, an elaborate coil handling concept which gives a chance to rewind of unfinished coils. By using serial straightening units, type RMA and RMZ, everything is well fitting. To achieve short mounting times and easy accessibility, the complete machine body features a one piece tiebar design machined with most modern CNC equipment. Coil Cradles, CradleStraighteners and CradleFeederStraighteners thus are very efficient too. Consequently, their compactness, efficiency, safety and operator friendliness melt into a coil handling solution which underlines GSW’s lead in technology. Performance data Up to 8 t coil weight, 700 mm stock width and up to 13mm thickness

Request for a quote

RK ROSE+KRIEGER GMBH

Germany

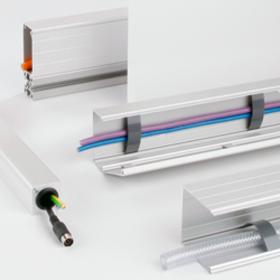

Fast assembly and perfect organisation Modern machines contain countless power, data and control cables, along with pneumatic hoses. In large systems, the total length of these can quickly add up to several thousand metres. Cable channels make it easier to organise and assemble these cables. The BLOCAN® cable channel system made from anodised aluminium impresses not only with its attractive design, but also through a multitude of well thought out details, which offer the customer considerable added value and greatly facilitate their work. The cable channels in sizes 40, 40x20, 40x80, 80x40 and 80x80 can be supplied as 6 metre bars or cut to length. They are also available with mounting holes, which is a new feature for aluminium cable channels. These can be very quickly attached to a BLOCAN® profile slot by means of a pivoting mounting clip.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The automatic feeding of tools from the tool magazine to the machining spindle is implemented in modern machining centers with the aid of a tool changer. At the same time, this device is used to return tools to the tool magazine. Reducing non-productive times is an important criterion for increasing the efficiency of machining centers. The chip-to-chip time is directly positively influenced by a fast tool change, i.e. a short tool change time.

Request for a quote

TECHNOTRANS SOLUTIONS GMBH

Germany

The use of direct cooling is always an advantage when a high cooling capacity is requires and the temperature differences between cooling water and circulating water are low. Here cooling water is directly and without temperature loss supplied to the circulation circuit. Absolute reliability, high regulating accuracy, easy operation and a favorable price/performance ratio: apart from the versatile performance features a modern temperature machine has to fulfill, these are the key criteria in the temperature controller wd series.

Request for a quote

FRIMO GROUP GMBH

Germany

One Concept, Many Applications FRIMO EcoForm machines provide state of the art technology that stems from more than 25 years of thermoforming expertise. These machines have the most modern technology in a compact, user-friendly form. They are designed as standardized single-station machines for vacuum forming and vacuum laminating films and sheet materials. They can also be used in the IMG ( In-Mould Graining) process. EcoForm Thermoforming Machines for Plastic Sheets EcoForm thermoforming machines for plastic sheets are the result of continuous product development and improvement and offer a concept superior in many technical details and convincing in terms of economic efficiency, operating convenience, and process reliability.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PERKUTE MASCHINENBAU GMBH

Germany

This cleaning machine "Rhönrad" is the ideal choice for the cleaning of parts with cropped areas, which needs to be moved during the cleaning process (rotate or swivel around the horizontal axis). Through the use of a special height adjustable lock-system also smaller baskets can be used without problems. Multi tank systems for special subsequent processes can complemented as well as drying and bath treatment systems. The PERKUTE-System: economically - environmental - effektive Basic unit § Stainless steel version § Compact and sturdy construction § Modern design § Powerful washing pump § High permissible basket load § Low water pressure switch as dry-run protection for pump and heating elements § Tank cover in the return flow, filter baskets incl. § Programmable Siemens S7-1200 touch panel control § Complete machine casing in modern design § Loading ramp incl. collection tray and grating for manual loading § Service hatch for cleaning activities § Mountings for fork-lift §...

Request for a quote

PERKUTE MASCHINENBAU GMBH

Germany

The extensive power spectrum of this solid production series in combination with the standard equipment coordinated optimally sets new standards in cleaning technology. The solid interpretation of the machine components connected with the modern design of the easy-care machine case completes the innovative machine concept. By the choice of specific accessory articles many possible applications open up. The PERKUTE-system: economically - environmental – effektive Basic equipment Made of stainless steel Compact and sturdy construction Modern design Powerful washing pump High permissible basket load Low water pressure switch as dry-run protection Tank cover in the return flow, filterbasket incl. Programmable operation operating counter incl. Housing insulation Loading carriage incl. Grate bearing Digital temperature indication Electronic basket drive (PF 100; PF 150) Square blast pipe system (PF 200) Rotation blast pipe system (PF 300) Adjustable feed

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

Our individually programmable cutting devices revolutionize the machining of aluminum and stainless steel as well as a wide variety of types of structural steel. Clean and burr-free cross-sectional images of hard as well as soft materials meet your high requirements. LVD Laser Electra FL 3005: Incredibly fast and flexible, the Electra fiber laser cutting system is ideal for ultra-high-speed cutting of thin sheet metal materials. The Electra can cut a wide range of ferrous and non-ferrous metals. • Ergonomic, modern design • Optimized machine design for maximum dynamics • Ultra-high-speed cutting • Processing speed up to three times faster than with CO² • Intuitive LVD Touch-L touch screen control • Highly efficient fiber laser source • Automatic shuttle table system Trumpf Laser: The new generation of the proven laser machine TruLaser 3040 combines innovative technologies and high laser power with a new design concept and optimized operation.

Request for a quote

A + H THOMAS GMBH + CO. KG

Germany

We manufacture punched parts made of aluminum, stainless steel or plastic according to your specifications using high-quality punching tools on our modern punching machines. We can mill or laser smaller quantities or sample parts made of plastic or non-ferrous metals on our CNC machining center or our CO2 laser systems and label them as required.

Request for a quote

A + H THOMAS GMBH + CO. KG

Germany

We manufacture your product for you with our modern screen printing machines and our expertise. In the subsequent print finishing, your product is punched, lasered or cut as required. The advantages at a glance: almost all materials can be printed UV-resistant, weather-resistant, water and abrasion resistant applicable for all color systems (such as RAL, HKS, NCS, Pantone) Special and effect colors according to customer requirements lasting durability Self-adhesive front panel in screen-printed quality with translucent windows, various cut-outs and raised keys

Request for a quoteResults for

Machine modernization - Import exportNumber of results

11 Products