- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting united

Results for

Cutting united - Import export

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

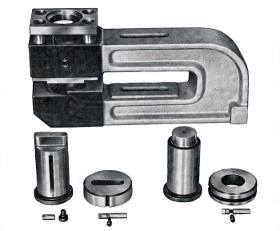

Punching units Punching unit with exchangeable cutting elements for sheets and profiles up to a material thickness of 25.0 mm and a hole diameter of 150.0 mm JOKA punching units consist of a special cast stand that accepts the punch and die and ensures the exact axis alignment between the cutting elements (punch and die). In addition, there is a stripping system in the upper part of the tool stand, as the material wipes off automatically after punching. The scraper contains two or more disc spring packages that guarantee perfect scraping even in the border areas. A fixed connection between the tool and the upper part of the press is therefore not required. To determine the exact position, each tool has a positioning pin (two for shaped holes) on the underside, which is precisely aligned with the cutting elements (center of the hole). The above picture shows a complete punching unit without cutting elements and one cutting set (punch and die) each for round hole or shaped hole.

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Horizontal End-Suction Pumps are centrifugal inline pumps with a compact design where the impeller is mounted onto the extended motor shaft. These pumps are not self-priming and must be gravity fed. All pumps are equipped with double mechanical seal. This pump series is designed for horizontal installations next to a tank and are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60 HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SBC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. Volumetric delivery: up to 1400 l/min Delivery head: up to 34 m

Request for a quote

BRINKMANN PUMPS K.H. BRINKMANN GMBH & CO. KG

Germany

Cutter Pumps The cutter pumps of the series SFC are capable of cutting aluminium chips and similar materials and pumping of these materials along with the coolant fluid. An agitator located at the pump suction helps to break up and separate any large bundles of chips or birds nests which reach the pump suction. The specially made cutting unit (>60HRC) is cuting chips and the above located semi-open impeller allows with its large clearances to pump the particles along with the coolant fluid from the machine back to the filter. The SFC pumps are capable of handling chip to coolant ratios of up to 1.5% by weight. The SFC pumps are equipped with the user-friendly 45 degree flange connection which allows for either vertical or horizontal pipe connection and the connection of a pressure gauge with G 1/4. Volumetric delivery: up to 1700 l/min Delivery head: up to 45 m Please contact us for delivery quantity.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ROHRE-KETTERER GMBH

Germany

is a cutting method that can be used for all material grades. The quality of the cut is superior to other cutting technolgies in precision, rectangularity and it is nearly burr-free. The result of the top quality machined surface is an optimized further processing of the parts especially if they have to be welded or soldered. Often there is no need to deburr the parts after the cutting. We cut with high precision and nearly burr-free on especially developed cutting units any geometry of tubes also shaped and manipulated parts without deforming the parts.

Request for a quoteResults for

Cutting united - Import exportNumber of results

7 ProductsCompany type