- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting united

Results for

Cutting united - Import export

BENZ GMBH WERKZEUGSYSTEME

Germany

Cutting - Many different materials, one unit Where wood previously dominated, today you see materials like leather or textiles moving into the production process. Leather-covered seating, foamed-lined instrument cases or lampshades made of pieced-together veneer parts – the list of application examples is long. Despite this new mix of materials, nothing changes for you in production. Thanks to the BENZ SECO cutting unit, you do not need any special machines. Rather, you are able to cut these materials easily on your CNC machine – and without any splintering.

Request for a quote

MONGIN

France

Unit dose pipettes precutting N°3 - Lengthwise precutting knife N°4 - Cross-cutting knife Precutting of unit dose pre-filled syringes N°5 - Precutting blade N°6 - Precutting knife for sealing machine Precutting for blister pack N°7 - Cross-cutting blade Precutting for blister packof medical reagents N°8 - Precutting knife

Request for a quote

EWS WEIGELE GMBH & CO. KG

Germany

Compact and stable – this is EWS' new swivel head. The swivelling module, which is equipped with a Cylkro drive system, is 17 mm smaller than standard heads which, above all, offers greater flexibility in swivel ranges between 0° and 45° in the field of cutting tools. The swivel unit covers an angle of +/- 92°. During the swivelling process, the supply of coolant is directly carried along. A distance of at least 48 mm from the contact surface to the swivel axis can be proposed. Even a high-pressure interior cooling system of up to 70 bar can be built into the module without the exterior dimensions having to be modified. Rotational speed limit is 6,000 1/min, maximum transmittable torque is 16 Nm, and max. cutting tool diameter is restricted to 10 mm. The swivel head is mainly suitable for drilling or for simple machining tasks. EWS' TWK range is available. for greater demands with regard to torque and performance.

Request for a quote

TRIBUNAS & FIGUEIREDO, LDA

Portugal

TF Metals offers a flat sheet laser cutting service for sheet metal up to 30mm in iron/steel - stainless/aluminum. We have 2 laser cutting machines: - Fiber Laser Cutting HK N-Light Corona 12KW with automatic loading and unloading - CO2 Laser Cutting HK Panasonic 4KW

Request for a quote

COLORSLED

China

Double leds per cut for 24V,easily for customized application Mini cut unit up to 16.66mm Parameter matches with traditional ones,better for stock management Self-encapsulated design offers 5 optional 2700-6000K white lights NO/NA/ET/SG/EG IP process

Request for a quote

COLORSLED

China

2 LEDs per cut for 24V,easily for customized application Mini cut unit up to 11.90mm Parameter matches with traditional ones,better for stock management Self-encapsulated design offers 5 optional 2700-6000K white lights NO/NA/ET/SG/EG IP process

Request for a quote

COLORSLED

China

6mm wide luminous surface, slim and delicate. Adopt silcone co-extrusion process, featured in strong bending and flexing resistance, can achieve various top bending styles. Small cutting unit, more precise size, more free design. Great protective performance with resistance against water, fire, aging and chemical corrosion. Innovative outlet solution, suitable for outline decoration of furniture and other installation applications

Request for a quote

COLORSLED

China

11mm wide large luminous surface, 120°beam angle. Adopt silcone co-extrusion process, featured in strong bending and flexing resistance, can achieve various top bending styles. Built-in COF LED strip, displays brilliant colors. Small cutting unit, more precise size, meet the requirements of dimension accuracy in project customization. Suitable for laminate furniture or display racks in shopping malls as display lighting

Request for a quote

THOMSON MACHINERY BV

Netherlands

Specifications Manufacturer 2008.0 Condition Used Description mobile automatic friction feeder Bograma FR 550 Servo C from year 2008 for creating brochures and single sheets for offline operation with: Bograma- Individual modules, Bograma cutting systems, third-party units, etc.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Okuma Model LU 300 M Year 2005 Condition Used Made in Japan Control Unit OSP-E100L Cutting hours 3500 H Turning diameter 370 mm Turning length 370 mm Bar capacity 62 mm Tailstock MT5 Head motor 22 / 15 KW

Request for a quote

THOMSON MACHINERY BV

Netherlands

Manufacturer Mori Seiki Model NL 2500 Year 2006 Condition Used Control Unit Mori Seiki Cutting hours 6450 h Head motor 18.5 kW Head size A2-8 Bar pitch 80 mm Rapid speed 30 m / min Spindle speed 4000 rpm Cutting torque 80 Nm Dimensions L 3100 x W 2000 x H 2232 mm Weight 5800 Kg Availability Immediately

Request for a quote

AVOLA MASCHINENFABRIK A. VOLKENBORN GMBH & CO. KG

Germany

CF 30 G equipment is supplied completely assembled and ready for operation. The dust collection unit is suited for intermittent operation only, because regular cleaning of the pocket filter element in certain intervals is an absolutely must for the proper operation of the equipment. The cleaning intervals will depend on the operating conditions and must be established by experience. Normally cleaning intervals will be between operating times of 30 minutes to two hours. It is a prerequisite for sufficient and intensive cleaning of the filter cloth that dust collecting is interrupted during cleaning to achieve static pressures on the filter material. A retention time of 1 - 2,5 minutes between the end of the suction and the beginning of the cleaning process is therefore required. The filtered air must be removed outside - do not lead back to closed rooms!

Request for a quote

KW HYDRAULIK GMBH

Germany

Cable cutting unit in several sizes for cutting cables, in case of failure under voltage.

Request for a quote

ELMESS-THERMOSYSTEMTECHNIK GMBH & CO. KG

Germany

Electronic temperature monitoring devices - Thermal cut-out - Thyristor units - Temperature controllers

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

The containers are picked up by the in feed star wheel and transferred to the container table. The container rotation begins when they are positioned between container plates and centering bells. The speed of the feed roller is adjusted to the required label length for continuous web tension. A standard threading unit ensures optimal film feed. In the cutting unit, the labels are precisely cut while a PLC command and servo-motor provide an exact cut-off point. Two narrow strips of hot melt glue the labels together, which are applied by a heated glue roller to the leading and trailing label edges. The label with the glue strip on its leading edge is transferred to the container. This glue strip ensures an exact label positioning and a positive bond. As the container is rotated during label transfer, labels are applied tightly. Gluing of the trailing edge ensures proper bonding. Process: In feed bottle → pre-position →label cutting → gluing → labeling → label by press out → finish

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

Servo-electric press lines Modular X2000NC setup as a press line with various servo-driven presses for cold forming Back wall dimensions: approx. 5 x 3.5 m, total weight: approx. 45 t Tool setup: 6 stations, 23 mm wire fed in from decoiler and feeder, straightener and cutting unit, ready-to-use production parts Cold extrusion process with press lines Illustrative example of a modular X2000NC setup with servo-driven presses of various sizes as a press line for the cold forming of wire. This setup with servo-driven presses from 240 kN to 7,000 kN can take the place of a single large press with a progressive die. Our press line with synchronised servo transfer is compact, fast and affordable. Unlike large presses from other manufacturers, our line does not need its own press pit. If you need a machine for processing thick wire up to 26 mm in diameter – we’re the specialists to call.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PRESSTA EISELE GMBH

Germany

Double mitre saw with a fixed unit on the left and the other one movable. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 22,5° and 135°. Realized with cutting lenght of 4000 mm (7650 mm with accessories), 5000 mm (9650 mm with accessories), 6000 mm (11650 mm with accessories). It is equipped with the system EC 700x. Electro-welded sheet base which has been designed in such a way to offer the maximum rigidity and use practicality. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Wide cutting capacity by means of sawblades Ø 450 mm. Possibility to use a blade with a dia. 500 mm, only by eplacing the tool. Dynamic protection guards for a total covering of the cutting area. Mist spray lubrication tools (Venturi system). Pre-arranged to connect an exhaust extractor for swarfs. Pre-arranged to use a set of tanks to collect swarfs. Pre-arranged to connect a motorised belt conveyor.

Request for a quote

FERPLAST SNC

Italy

MG 300 SEALING MACHINE WITH CLOSING MAGNET Impulse sealers MG 300 series, with 300 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. Maximum weldable thickness 0.15 mm (0.30 tot). Available models: MG 300: bench sealing machine with manual closing of the bars MGM 300: bench sealing machine with motorized bar closing and electric pedal

Request for a quote

PRESSTA EISELE GMBH

Germany

A double head mitre saw with disappearing blades specifically studied for the tubular steel shapes. Automatic positioning of the movable unit. Electronic positioning of the cutting units on any angle within 45° and 135°. It is equipped with the system TS 690. Frontal and straight blade feed with speed adjustments. Hydro-pneumatic blade feed. Speed of rotation of the blades, variable by means of a frequency converter (inverter). Automatic shifting of the support plates of the profile once over the cutting cycle. Dynamic protection guards for a total covering of the cutting area. Blade lubrication cooling system with electric pump. Coolant liquid vat with extractable pump for vat cleaning. Cutting deepth stop device. Intermediate workpiece support automatically operating Mobile roller conveyor with pneumatic clamp for section support Compressed air treatment unit (filter/reducer/lubricator)

Request for a quote

FERPLAST SNC

Italy

Impulse sealers MG 820 series, with 820 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealers bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. Available models: MG 820: bench sealing machine with manual closing of the bars MGMI 820: bench sealing machine with motorized bar closing and electric pedal

Request for a quote

FERPLAST SNC

Italy

Impulse sealers MG 621 series, with 620 mm sealing bar and suitable for sealing polyethylene, pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. There are special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized bar closing. The MG 621 series sealing machines are available with mechanical or motorized closing bars with 3 or 5 mm sealing thickness depending on the model. Also available in stainless steel with mechanical closure of the bars and and 3 mm sealing.

Request for a quote

FERPLAST SNC

Italy

MG 421 SEALING MACHINE WITH CLOSING MAGNET Impulse sealers MG 421 series with 420 mm sealing bar and suitable for sealing polyethylene pvc and polypropylene bags. They have a special timer for adjusting the sealing time based on the thickness and type of material. The MG sealers are complete with a manual cutting unit for the trimming of the sealed bags and/or the creation of bags from tubular reels (if the machine is equipped with a roll holder). The sealing bars must be closed manually by the operator and are automatically held by a magnet until the end of the cycle. They can be equipped with special supports with mechanical pedal, for the manual sealing machine and with electric pedal for the sealing machine with motorized closing of the bars. The MG 421 series sealing machines are available with bars with mechanical or motorized closure with a sealing thickness of 3 or 5 mm depending on the model. There are also special models in stainless steel and with 2 parallel welds of 3 mm.

Request for a quote

JOKA WERKZEUG- UND MASCHINENBAU GMBH & CO. KG

Germany

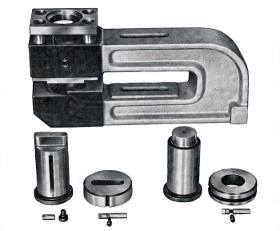

Punching units Punching unit with exchangeable cutting elements for sheets and profiles up to a material thickness of 25.0 mm and a hole diameter of 150.0 mm JOKA punching units consist of a special cast stand that accepts the punch and die and ensures the exact axis alignment between the cutting elements (punch and die). In addition, there is a stripping system in the upper part of the tool stand, as the material wipes off automatically after punching. The scraper contains two or more disc spring packages that guarantee perfect scraping even in the border areas. A fixed connection between the tool and the upper part of the press is therefore not required. To determine the exact position, each tool has a positioning pin (two for shaped holes) on the underside, which is precisely aligned with the cutting elements (center of the hole). The above picture shows a complete punching unit without cutting elements and one cutting set (punch and die) each for round hole or shaped hole.

Request for a quote

BIZERBA SE & CO. KG

Germany

Flexible sawing system for industrial food production The FK 32 Heavy Duty Meat and Bone Saw is made entirely from stainless steel with high IP protection and with top quality construction all round. Depending on production environment and the food to be processed, this saw is available with a variable work area or can be mobile by adding optional stainless steel wheels. Ergonomic and effective Heavy Duty Meat and Bone Saw cutting and portioning of fresh and frozen foods. This unit will easily cut through fresh and frozen fish as well as heavy cuts of frozen meat including the bones. The Heavy Duty Meat and Bone Saw is ideal for industrial use and has a number of optional extras that you may want to consider to include a Sliding table with removable remnant holder additionally a Stainless steel bench type stand with feet a Mobile CE compliant version, Special saw blades depending on the material that needs to be cut. Safety features. Safety In designing the Heavy Duty Meat and...

Request for a quote

APD MAQMASTER

Spain

Designed as a profile cutting center with control 3-axis numerical for cutting aluminum, PVC and all kinds of Light alloy profiles. The cutting unit with a 550 mm diameter disc can cut at any angle between 30° and 150°, offering a Wide cutting range. It has a feeding capacity of 10 profiles, which makes it an exceptionally efficient cutting center.

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

SEAMIAUTOMATIC SEALING DEVICE suitable for the sealing of all sorts of plastic and glass containers. 1. foil application device PolySeal Vario DIS (left hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale foil dispensing with 2 spot pre-sealing removable pre-sealing plates heat protection shield vacuum suction nozzle roller guide with running slide foil magazine for stackable pre-cut sealing lids VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure 2. sealing device PolySeal Vario PN (right hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale sealing head heating block, swingable, anodised aluminium hollowed out sealing die heat protection shield container holder VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure

Request for a quote

SCHNELL SPA

Italy

Electromechanical mesh cutting machine. It cuts in two directions thanks to the two kW 3 cutting motors, a kW 0.75 press motor and a kW 0.55 feeding motor. It is equipped with Reinforced framework; Continuous shear cutting unit; Rubber inlaid meshpressing beam.

Request for a quoteResults for

Cutting united - Import exportNumber of results

120 ProductsCountries

Company type

Category

- Industrial cutting machine tools (14)

- Food industry packaging machinery (9)

- Automation - systems and equipment (8)

- Air disinfection - equipment and systems (7)

- Plasma cutting machines (6)

- Package sealing machinery (5)

- Lighting (4)

- Metal industrial presses (4)

- Laser - cutting and welding machines (3)

- Paper - Printing - Machines & Equipment (3)

- Woodworking - machinery and equipment (3)

- Confectionery - machinery and equipment (2)

- Cooling and lubrication pumps (2)

- Food packaging (2)

- Machines for the manufacture of PVC and Aluminium Doors and Windows (2)

- Metallurgy - machinery and installations (2)

- Punching machine tools (2)

- Rolling mills - machinery and installations (2)

- Bakery - machinery and equipment (1)

- Bottling and filling - machinery and equipment (1)