- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- cutting of tubes

Results for

Cutting of tubes - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

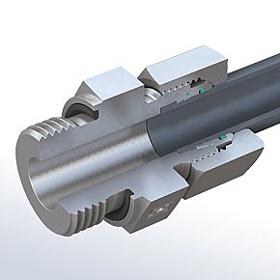

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 28 x 2 mm for stainless steel tubes Shortest separation length: — 25 mm (without pull apart) — 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 50,8 x 2,5 mm Shortest separation length: - 25 mm (without pull apart) - 55 mm (with pull apart) Separation efficiency: up to 2,000 pcs per hour

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 80 x 3 mm Shortest separation length: - 70 mm (without pull apart) - 100 mm (with pull apart) Cycle time: 5-10 sec. (depending on material, diameter, wall thickness and cutting length)

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

There are many good reasons to separate tubes chiplessly. And first of all, of course, the cleanliness. Precision and output, too, are not insignificant. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can be formed immediately afterwards. That saves time and money. Technical specifications: Separation efficiency: max. Ø 105 x 3 mm Shortest separation length: - 100 mm (without pull apart) - 170 mm (with pull apart) Cycle time: 5-10 sec. (depending on material, diameter, wall thickness and cutting length)

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

Created for precision. Our chipless orbital cutting machines make precise cutting results possible. Your tubes can then be directly processed further and for instance be formed straight afterwards. That saves time and money.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TRANSFLUID® MASCHINENBAU GMBH

Germany

Fewer steps to the finished workpiece With t project you can see all the variables of the bending process before you start the production. Adapted to the material and collisionfree, it makes it possible to plan and execute complex bending geometries. The virtual bending simulation determines exact bending timings and cutting lengths; it also tests tube geometries in advance for feasibility. Tube data and bending results are documented with accuracy and they can then be replicated 100% . All the most common interfaces are available for the import and export of data and connection to BDE or ERP over the network.

Request for a quote

TRANSFLUID® MASCHINENBAU GMBH

Germany

In form, double strength. For the optimum processing of your individual requirements we simply combine our transfluid forming techniques, as simple as that, in particular the axial forming and the rollforming. The additional clamping unit makes even extreme forming feasible in one work sequence. The cutting before the axial tube forming is also possible, as well as the rollforming of a preformed geometry. That saves you valuable time. A strong partnership axial forming and rollforming. Our t form combination machines is the perfect union of axial and rolling tube processing, with up to 6 axial forming steps, two rollforming stations, two powered tool holders for flange orientation and an additional clamping unit. The horizontal clamping system makes the processing of bent tube geometries possible.

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

The electro-hydraulically operated STAUFF Press Assembly Machine SPR-PRC-MA allows the assembly of cutting rings in the Light Series (L) as well as in the Heavy Series (S) according to ISO 8434-1 / DIN 2353 on metric tube ends with outer diameters from 4 mm to 42 mm. Exchangeable heads allows the device to be adapted for 37° flaring of metric and imperial tube ends with outer diameters from 4 mm to 42 mm and from 1/4 in to 1 1/2 in respectively according to DIN 3949 or SAE J514 / ISO 8434-2. Short times for tool changes, setup and assembly (even when changing the assembly type from cutting ring assembly to 37° tube flaring) make it possible to carry out series production as well as the assembly of small and medium quantities with a high level of economic efficiency, reproducibility and process reliability with considerable reduction of times and cost of assembly of fittings. The adjustable return stoke of the cylinder helps the operator to further optimise the total cycle...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Soft-Sealing Cutting Rings provide an additional safety and protection against potential leakage risks, e.g. caused by the settling of purely metallic sealed connections, temperature fluctuations or considerable pressure and vibration loads in the system. "Sweating effects" on the connection points can be permanently avoided. The type FI-WDDS Soft-Sealing Cutting Ring of the STAUFF Connect range is characterised by the elastomer sealing, which is located in a specially designed groove close to the rear end of the 24° taper and protected to prevent loss. An additional o-ring is used to secure the secure the second potential leakage path between the cutting ring and the tube – even in the event of unfavourable tolerances FKM/FPM (Viton®) is used as the standard sealing material and enables problem-free use of the system for challenging applications involving high temperatures or aggressive media. Like all other components in the STAUFF Connect product range, the cutting ring...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

STAUFF Connect 24° Tube Fittings with Cutting Ring have been developed and designed for the reliable, leak-free connection of metric tubes with outside diameters between 4 mm and 42 mm / between .16 in and 1.65 in respectively. Therefore, the most relevant key dimensions of the tube fittings (e.g. through bores and widths across flats) also have metric dimensions. With regards to their dimensioning and general design, STAUFF Connect 24° Tube Fittings with Cutting Ring fully comply with the latest versions of the ISO 8434-1 and the DIN 2353 standards. The operating principle of STAUFF Connect 24° Tube Fittings with Cutting Ring is based on a double-edge cutting ring, which cuts into the tube twice, thus ensuring the necessary force and form closure in the cutting area. Thanks to the optimised geometry of this ring, the two edges do not cut simultaneously, but rather one after the other. In addition to increasing the incising effect, this method maximises the tear strength of...

Request for a quote

WALTER STAUFFENBERG GMBH & CO. KG

Germany

Manual Final Assembly Stud Type FI-FK Manual Final Assembly Studs of the FI-FK series facilitate the final assembly of cutting rings on tube ends, thus allowing for consistent assembly results with a maximum degree of accuracy, reliability and process stability Characteristics and Features Manual Pre-Assembly Stud Type FI-VK Manual Pre-Assembly Studs of the FI-VK series facilitate the pre-assembly of cutting rings on tube ends, thus allowing for consistent assembly results with a maximum degree of accuracy, reliability and process stability Characteristics and Features

Request for a quote

C. AUGUST HÜCHELBACH GMBH & CO. KG

Germany

Our high-grade friction saw blades, MALTESERKREUZ BRAND, are used among other things for cutting profiles, thin-walled tubes, gratings etc.. It is characterised by its high abrasion resistance and a long life-time. Basic version in material 80 CrV 2 (material-no. 1.2235) chrom-vanadium-steel, plain hardened, hollow or surface ground, tensioned and straightened. Tooth geometry: Tooth Trennjäger; pointed toothing Standard Dimension: 400 x 3,0 mm 240 teeth 450 x 3,0 mm 240 teeth 520 x 3,0 mm 300 teeth 520 x 4,0 mm 300 teeth 550 x 4,0 mm 300 teeth 600 x 4,0 mm 300 teeth 700 x 5,0 mm 300 teeth 1000 x 8,0 mm 350 teeth

Request for a quote

ROHRE-KETTERER GMBH

Germany

Cutting or sawing tubes to required lengths is often only the beginning of multiple treatments necessary on the way to a finished part. We can offer machining fulfilment no matter if your parts have to be milled out, drilled or worked. Or have to be stucked and need a thread insert or durface treatment.Or all of this together. Our samples show you a range of the possibilities we have to fulfill your needs.

Request for a quote

ROHRE-KETTERER GMBH

Germany

is a cutting method that can be used for all material grades. The quality of the cut is superior to other cutting technolgies in precision, rectangularity and it is nearly burr-free. The result of the top quality machined surface is an optimized further processing of the parts especially if they have to be welded or soldered. Often there is no need to deburr the parts after the cutting. We cut with high precision and nearly burr-free on especially developed cutting units any geometry of tubes also shaped and manipulated parts without deforming the parts.

Request for a quoteResults for

Cutting of tubes - Import exportNumber of results

15 ProductsCompany type