- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- customised solutions

Results for

Customised solutions - Import export

ROLLON GMBH

Germany

1, 2 and 3 Cartesian axis linear modules with rack and pinion drive guarantee precise manipulation of loads from 10 up to 2000 kg with fast and silent functioning. Our main application fields are: robotics, palletization, production line, logistics and manufacturing machines with Cartesian axis movements. Our products stand out for their: easy and quick assembly; high quality and competitive performances; reduced and simplified maintenance; wide range of integrated solutions; possibility of customised solutions; constant technical support and CAD drawings available. Strong points include: hardened sloping tooth racks (ground on request); payloads from 10 to 2000 Kg; up to 12-m beams (longer lengths can be obtained with jointed versions), high level torsional rigidity, precise shape; precise machining of all profiles (on request: repeatability up to +/-0.05mm); hardened and ground steel guide rails, for rollers and ball slides with cage; easy installation of pre-assembled systems...

Request for a quote

IGUS® GMBH

Germany

- Low-maintenance system for travel up to 100 m - Other sizes and versions available, travel up to 200 m and more with E2 roller e-chains® - Protection against weather and dirt exposure - Cost-effective and fully enclosed complete solution - Standardized and modular design - Simple wall assembly or optional floor mounting - Cable lengths up to 50% shorter than festooning, low-profile installation and no cable junction - Cables are at all times guided with a defined bending radius, and tensile forces are absorbed by the e-chain® - Cables cannot hook, jam, or tear - No slip ring contacts (as is the case on motor drums) -Cables or hoses can easily be retrofitted at any time Reduce electricity costs - direct drive due to scraper, no additional drives needed (as is the case on motor drums) Scraper arm (e.g. as mechanical connection to the scraper carriage) optionally available - we document the situation on-site and will propose a customised solution

Request for a quote

LAWECO MASCHINEN- UND APPARATEBAU GMBH

Germany

For manufacturers and operators of rails and utility/commercial vehicles, LAWECO designs customised solutions for assembly work, e.g. for the installation and removal of drive units.

Request for a quote

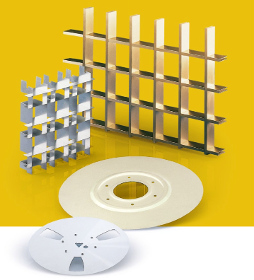

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Based on proven coil anodizing technology from our B57S® product, B73A can be used for shelving, furniture, medical and domestic appliances and many other applications. The surface of Novelis B73A is industrially pre-treated and coil anodised in a continuous process. This ensures a consistent high quality and is therefore the most cost-effective solution for the customer. B73A offers customised solutions with different functional and decorative requirements for the electronic, domestic appliances and chemical industries*. Our delivery program offers a wide product range, including a variety of colours and standard coating thicknesses. Standards are available in 1 ton lots on a short delivery time. *Please note: Due to the hardness of the anodic film, crazing can occur during extreme bending or forming. To minimise the effect more information is available on request.

Request for a quote

SCHMALE GMBH & CO KG

Germany

Our fastening machines can be adapted or constructed to customer requirements. Benefits / Characteristics • (Special shapes for customer products. E.g. oblique section cases, round cases, attaching to solid wood, etc…) • Highly automated solutions • Disability adapted machines • Fastening solutions for fittings of all types e.g. picture frames, jewellery hooklets etc…

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Customised system or individual part solutions are our core competence at KIS. We develop complete solutions for you based on our own KIS products and combine them with our comprehensive service for drive technology. Whether it's a careful selection of individual components or proper assembly ensuring your application functions perfectly: As bearing specialists based in Germany, we’re there for every step of the process, from development and construction, through monitoring of production and assembly, to quality inspections and practical tests.

Request for a quote

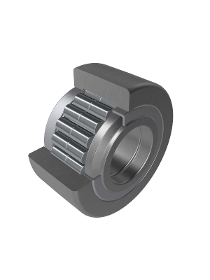

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

Our yoke type track rollers are available as single or double row needle roller or cylindrical roller bearings. Depending on the application requirements, the KIS range offers different ready-to-fit variants. Equipped with particularly thick-walled outer rings, our yoke type track rollers can support high radial loads and tolerate axial loads from minor misalignments, skewed running or short-term start-up shocks. Yoke type track rollers are mounted on axles and supported on a flat raceway (mating track). To meet specific requirements, we offer a wide range of different variants. Together with you, we develop the customised KIS solution carefully considering the use of cages, rib rings, seals and the profile of the outer ring running surface.

Request for a quote

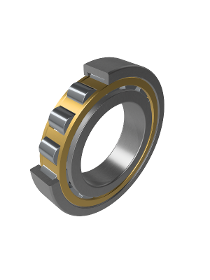

KIS ANTRIEBSTECHNIK GMBH & CO. KG

Germany

We offer our KIS cylindrical roller bearings in various designs and sizes. In addition to the number of roller rows and the design of the cage, the flanges on the inner and outer rings are also considered. Due to their low friction and high rigidity, our cylindrical roller bearings are the perfect, durable solution for applications with high radial loads. They can also compensate for axial displacements (e.g. due to thermal expansion) and are available in sealed designs. Sealed cylindrical roller bearings are protected from dirt, water and dust. The seal prevents the ingress of contaminants and keeps the lubricant in the bearing. Together with you, we will be happy to develop a customised KIS solution for your requirements.

Request for a quote

BERNSTEIN AG

Germany

The aluminium control enclosure CC-5000 neXt offers a unique design with a number of accessories such as the status light. The rounded contours ensure the enclosure is highly recognisable in machinery and mechanical engineering applications. — Customised solutions to your specifications — Innovative and modern industrial design — Freely selectable width and height (max. 1.000 x 1.000 mm) — Depths from 75 mm up to max. 370 mm — Rounded edges, no risk of physical injury — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Optimum heat dissipation due to aluminium sections — Integrated recessed grips for simple handling — Protection class IP65 — Internally-mounted front panel — Door configurations for direct access to the interior — Slimline design for configuring flat screen systems

Request for a quote

BERNSTEIN AG

Germany

The CC-4000 / CC-4000 SL are modular aluminium control enclosure systems. With their outstanding technical features, the enclosures simply and efficiently encapsulate industrial controllers and operator control panels for centralised and decentralised automation in production processes. — Customised solutions to your specifications — Simple and modern industrial design — Freely selectable width and height (max. 800 x 800 mm) — Depths from 52 mm up to max. 646 mm — High-quality extruded aluminium sections (naturally anodised) — Coloured areas that emphasize the design — Optimum heat dissipation due to aluminium sections — Integrated handle elements with vertical section — Protection class IP65 — Front panels internally-mounted or externally-mounted — Internal grooves for fixing components — Product features SL (in addition to CC-4000) - Two enclosure depths (55 und 99 mm) - Slimline design - For encapsulating flat IPCs

Request for a quote

BERNSTEIN AG

Germany

The CC-3000 light-duty operating enclosure is particularly suitable for encapsulating operator control panels, industrial computers and display components and, thanks to its modular concept, can be simply adapted to versions tailored to specific customer requirements. — Customised solutions to your specifications — Monitor-based industrial design — Freely selectable width and height (max. 600 x 600 mm) — Depths from 120 mm up to max. 255 mm — High-quality extruded aluminium sections (naturally anodised) — Customised colours from RAL range — Five possible enclosure designs — Optimum heat dissipation due to aluminium sections — Front panels internally-mounted or externally-mounted — Protection class IP65 — Screw-fixed or hinged rear panel — Internal grooves for fixing components — Extensive range of accessories

Request for a quote

FILLTECH GMBH

Germany

Made-to-measure gas supply If you are looking for a customised solution for your gas filling project, take advantage of our expertise and long experience for efficient, customized concepts. Together we will develop initial ideasinto tailored reliable systems. For the widest possible range of requirements in connection to the supply of gases, Filltech offers a solution; from compact stainless steel cartridges through various cylinder sizes and connecting valves to the development of filling plants. Gasfilling services Next to the production of custom-made gas filling stations, Filltech can als offer you additional gas filling services. The filling of cylinders with various gases such as carbon dioxide, noble gases, flexible and oxygen mixtures can be realized at our premises. From the ideato the optimal solution There is only one priority: the optimal design of your application with the appropriate requirements. In addition, our solutions can be flexibly integrated into your system. F

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine technology developed for coating round steel tubes with a temporary corrosion protection convinces with its high performance. The surface quality of the solvent free coating with 100 % UV lacquer, the fast curing time of ≤ 1 second as well as an overspray recovery rate of more than 95 % are impressive features which, by their very nature, offer high economic efficiency. Additional modules individually perform either the cleaning work, dust removal or marking of tubes. This machine technology ensures perfect transport of the tubes without damage to the lacquer coat, while flexibly taking tube properties into account, such as sleeves or caps, diameters from 20-200 or from 200 to 500 mm, required throughfeed speeds of 30 - 100 m/min as well as surface temperatures from +1°C to +40°C. Whether operated as an individual machine or integrated in an adjustment line, the output parameters are characterised by minimum space requirement and low operating and maintenance costs. An alkaline cleaning station that adjusts to the individual degree of soiling of the tube surface to ensure optimum results can be optionally installed together with a drying unit upstream of the pipe coating line. Venjakob offers individual system solutions for coating tube sleeves. This includes the application of a base coat and coloured rings, as well as marking. Customised solutions for tube marking are available as an option.

Request for a quoteResults for

Customised solutions - Import exportNumber of results

14 ProductsCompany type