- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- copper ores

Results for

Copper ores - Import export

SPANSET SECUTEX GMBH

Germany

“Heat”resistant buffer pad For hot processing. Nonferrous metals, such as gold, copper or brass, get hot during processing and have a sensitive surface. Rollers and cylinders coated with secutex Heat protect bar stock during production; abrasion and run marks are reliably avoided. Operating temperature up to 140°C Apart from the positive mechanical and chemical properties, secutex Heat is an elastomer material for operating temperatures up to a maximum of 140°C. Operating temperature up to 180°C As an option, „Heat“ can be finished with an aramide fibre surface. The operating temperature thereby even increases to a maximum of 180°C.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Brass float valves of open design in 3 and 4 inches can be combined with our hollow float balls made of high-quality PE-HD plastic (max. 70 °C), alternatively also with copper or stainless steel balls. The chemical nickel plating provides corrosion protection.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

The diaphragm float valves series F can be combined with our float hollow balls made of high-quality PE-HD plastic (max. 70 °C), alternatively with copper or stainless steel balls for high temperatures. This series has drinking water certification ACS, this grants the suitability of products with drinking water.

Request for a quote

P.V.A. PLASTIK-VENTIL-ARMATUREN GMBH

Germany

Brass float valve with high filling capacity. This is the PVA Series 8 external thread open type. This float valve is combined with hollow float balls made of high-quality PE-HD plastic (max. 70 °C), alternatively also with copper or stainless steel balls.

Request for a quote

N&H TECHNOLOGY GMBH

Germany

Powder technology has a long history in various sectors such as the chemical, food, pharmaceutical and metal industries. Measuring the physical properties of powder is very difficult and each industry uses different assessment methods. The PD-600 powder measuring system is the further development of the PD-51. It can determine the physical properties of powder via resistivity. Powder materials of carbon products: Materials used for rechargeable battery electrodes, condensers and resistance material and insulating electronics / cokes / graphite / carbon black / carbon fiber / nano carbon, etc. Metal powder: Materials used for battery electrodes, thin film materials such as copper powder or ITO powder, for circuit board materials, for example conductive paste and electro conductive paint. Others: Thermoplastic powder, Printer toner, Magnetic material such as ferrite, food material, pharmaceutical related and automobile parts.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELVION HOLDING GMBH

Germany

The wide range of product portfolio of coils with different tube diameters, tube patterns, fin profiles, materials and options allows us to customize our coils for any specific application and fluids: air heaters, air coolers, condensers and evaporators for HVAC and various industrial applications. Kelvion heat exchanger coils are manufactured with copper tubes and aluminum or copper fins. The fins are equipped with special profiles developed at our R&D department enhancing heat transfer and keeping pressure drop at a moderate level. The customized fin spacing is achieved by collars which also provide the contact between the fin block and the tubes. Mechanical expansion of the tubes guarantees a perfect bond between the fins and the tubes leading to maximum heat transfer between both fluids.

Request for a quote

ABS SAFETY GMBH

Germany

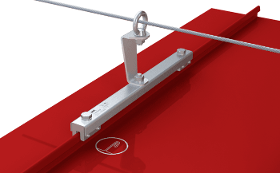

This stainless steel intermediate bracket - specially designed for lifeline systems - was developed for penetration-free installation on a standing seam roof. This device is attached using aluminium or brass clamps depending on your subsurface (steel, copper, aluminium or titanium zinc). EN 795:2012, C + CEN/TS 16415:2017 Clamped onto a standing seam without penetrating your roof surface Mounted on a single seam For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Designed exclusively for use in a lifeline system Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

Depending on the subsurface (steel, copper, aluminium or titanium zinc), this stainless steel anchorage point can be installed on a metal roof using either aluminium or brass clamps. It is simply attached to a standing or copper standing seam using the specially-designed clamps supplied - completely penetration-free. EN 795:2012, A + CEN/TS 16415:2013 Freely-rotating anchor eyelet Clamped onto a seam without penetrating your roof surface Mounted on a single seam For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; titanium zinc and aluminium ≥ 0.7 mm For Rheinzink and similar systems Incl. installation set

Request for a quote

ABS SAFETY GMBH

Germany

This stainless steel anchorage point can be installed on standing seam roofs made of steel, copper, aluminium or titanium zinc without penetrating the roof surface. Depending on the subsurface, this kind-to-your-roof device is attached using the aluminium or brass clamps supplied in the package. EN 795:2012, A + CEN/TS 16415:2017 Clamped onto two adjacent seams - completely penetration-free Seam intervals: 300 - 450 mm / 420 - 660 mm For steel and stainless steel ≥ 0.5 mm; copper ≥ 0.6 mm; aluminium & titanium zinc ≥ 0.7 mm For Rheinzink and similar systems; also suitable for copper standing seam panels (Cu) Incl. installation set

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Copper zirconium for welding applications spot welding

Request for a quote

NAGLER NORMALIEN GMBH

Germany

Tungsten copper electrode for EDM applications

Request for a quote

VERFAHRENSTECHNIK HÜBERS GMBH

Germany

Impregnation systems to close micropores in metal castings as well as in copper, aluminium or magnesium alloy castings. The parts to be impregnated are fixed in baskets. The latter are transported by a special crane system as well as with reservoir roller conveyors. Excess material is removed by centrifuging of the baskets. The impregnating agent remaining in the pores in fluid form is hardened by heating in a hot water bath. The process sequence runs fully automatically under a microprocessor control.

Request for a quoteResults for

Copper ores - Import exportNumber of results

13 ProductsCompany type