- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- all forming

Results for

All forming - Import export

TRANSFLUID® MASCHINENBAU GMBH

Germany

With the new generation of our combination machines, we have continued to develop the new diversity for forming pipes. Geometries that effectively replace high-cost and expensive turned parts can be formed directly at the pipe end in the endforming machine – for a final component of a single workpiece that is ready for use without elaborate soldering or welding. Implementation of the combination can be specified by you or based directly on the forming geometry. This is usually done using up to 6 axial forming stages and at least one rotary unit. Trimming, as well as axial and rotary forming, may require 2 rotary forming stations. Simple trimming or deburring after forming at the pipe end are no demanding challenges. Therefore, all our axial forming machines and combination machines are equipped with one or several single-drive axes. They have a servo-electrical drive and can be used in each of the holders for the forming stages, making the system is very flexible and compact.

Request for a quote

JERKO-SPRÜHSYSTEME GMBH

Germany

Jerko flow measurement is a unique success story since the beginning of the project. At the request of the German Massivumformung e.V., a sensor system for the reliable detection of spray quantities was developed. Of course, the partners of Massivumformung e.V. could rely on the innovative power of Jerko and now have the possibility to monitor their process even better. The sensor is suitable for all common forming lubricants - whether they contain oil or solids. Even non-Newtonian fluids are reliably detected. The sensor has a space-saving design and can be integrated into almost any spray system, even retrospectively. With the sensor you know even before the next forming operation whether the tool has been supplied with the required amount of lubricant and eliminate the resulting tool damage or consequential costs.

Request for a quote

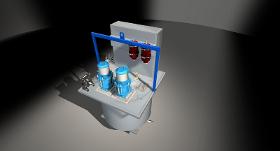

JERKO-SPRÜHSYSTEME GMBH

Germany

Our supply tanks are suitable for all common lubricants. No matter if graphite containing, salty or oil based products, the Jerko spraying unit is equipped for all applications. Standard sizes form 250 litres up to 2.000litres Due to the special surface and well thought-out cleaning function, the unit is durable and requires low maintenance. For cleaning, the complete cover can be lifted off with a few simple movements. This modular system allows easy replacement of the components. The necessary pressure to supply the spray equipment is generated by a piston pump developed by Jerko with a transmission ratio of 1:3.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The high-rack store is primarily for linking board production with the downstream processing systems. Formatted raw-board stacks from board production and boards with papers for board lamination are stored intermediately in the high-rack store and delivered to the downstream systems as required. The high-rack store may be installed separately or combined with complete transport systems for connection to the production systems. Tailored to customer requirements, the high-rack store is designed with all the components needed for storage / removal and connection to the production facilities. Our goal: to achieve the best product in all forms through the optimum use of resources! The machines used are tailored in the best way possible to the products, the required capacity and interactions. It is possible to take account of extension stages from the start. Advantages Optimum use of space Safe and gentle material transport

Request for a quote

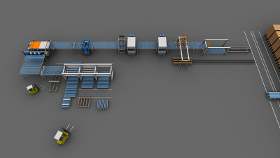

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

The sanding / saw line manufactures the end product to be sold / the basis for subsequent processes – e.g. lamination – from the master board. Very smooth surfaces and dened dimensions may be realised with great accuracy. The sanding line may be installed separately or combined with the saw line as a closed concept. The sanding machine, saws and other process components are designed and combined on the basis of customer requirements. Our goal: to achieve the best product in all forms through the optimum use of resources! Advantages High capacity Safe and gentle material transport, short conveying distances due to direct connection to machines High exibility Rapid access times Optimum coordination of the machines used with the products, the required capacity and interactions

Request for a quote

HANS KÖRBER GMBH

Germany

Our range of elbows covers a broad spectrum of measurements, standards and materials for all forms of use in pipeline construction – up to and including those applications with the highest safety requirements. Unusual angles? Non-standardised radii? Limited tolerances? No problem for us – we develop the solutions together with you and customise them to your needs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

All forming - Import exportNumber of results

6 ProductsCompany type