- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- air exhausters

Results for

Air exhausters - Import export

KUBOTA BRABENDER TECHNOLOGIE GMBH

Germany

— Filtering of displaced air during loss-in-weight feeder refill — Filter cartridge with filter material made of polyester fleece (conforms to FDA and GMP directives) — Trapped dust is automatically cleaned by pulses of compressed air (dust falls back into the feeder eliminating ingredient waste) — Models available for hoppers up to 1000 dm³ (35.3 ft³)

Request for a quote

ANTHERMO GMBH

Germany

Air-water / air-air heat exchanger as smooth tube heat exchanger up to 1,000 ° C Smooth tube heat exchanger as an air / water heat exchanger In the case of air-water heat exchangers (also called gas-water heat exchangers), a temperature exchange takes place between a gas (usually air) and a liquid. As a rule, the liquid medium flows inside the pipes, while the gaseous medium flows around the pipes outside the pipes. Smooth tube heat exchangers can cover various areas of application: heating, cooling and condensing as well as heat recovery. Smooth tube heat exchanger as air-to-air heat exchanger Smooth tube heat exchangers are also often used as air-to-air heat exchangers. In this application, a gas (e.g. exhaust air or exhaust gases) flows inside the pipes and a gas (e.g. fresh air) outside the pipes around the pipes.

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

Our OHLER product line is specifically designed for use in automobiles and caravans. Novelis is one of the leading suppliers of flexible tubes and hoses for the automotive sector with products used for heat protection, air ducts, exhaust pipes, thermal insulation and energy absorption.

Request for a quote

ANTHERMO GMBH

Germany

Temperature control of gaseous and liquid media Flat tube heat exchangers are generally used as air / air or air / liquid heat exchangers. Flat tube heat exchangers are used where the (exhaust) air is polluted and the installation space is limited. In heat recovery in particular, there are numerous applications for flat tube heat exchangers as so-called exhaust gas / exhaust air heat exchangers. Little installation space and less pressure loss While the rows of tubes in smooth tube heat exchangers consist of round tubes, the rows of tubes in flat tube heat exchangers have a special profile (see illustration). This special tube profile offers advantages over the round profile in certain applications. Flat tube heat exchangers require less installation space than smooth tube heat exchangers with the same exchange area and are therefore also lighter.

Request for a quote

ANTHERMO GMBH

Germany

Heat recovery with the help of heat exchangers In industry, waste heat occurs at many points in the production process, which is often released into the environment without being used. In many cases, energy is even used to cool the waste heat flows from production so that they can be released into the environment. Heat exchangers (also called heat exchangers) are used for heat recovery so that the waste heat generated in the production process can be used again in the company. Gaseous or liquid media Waste heat can be in the form of gaseous media (e.g. warm exhaust air, steam, exhaust gases, etc.) or in the form of liquid media (e.g. hot water or other liquids). With the help of heat exchangers, the waste heat can be recovered from both gaseous and liquid media and then made available to the production process at a suitable point as energy in gaseous or liquid media. This process is known as energy recovery or also as heat recovery.

Request for a quote

WIWOX GMBH SURFACE SYSTEMS

Germany

Thermal cleaning in the WIWOX® IGS thermal system at up to 500° C removes all organic residues, even from fine bores. Depending on the melting and decomposition point of the residues, they are either melted or pyrolysed. The resulting exhaust air during the carbonization phase is burned in the afterburner chamber at over 850° C. Cleaning in the pyrolysis process requires subsequent post-cleaning. Inorganic components, oxidation residues, corrosion, etc. remain on the tool surface and must be removed. The ultrasonic process with acidic or alkaline cleaning media or the blasting process with organic and mineral abrasives are suitable for this purpose.

Request for a quote

TROTEC GMBH

Germany

Practical benefits: Professional quality "made in Germany" - Original Trotec fabrication Extremely powerful radial blower- max. 1.050 Pa - optimal for ventilation over long hose distance Adjustable air flow up to max. 1.250 m³/h Carrying and stackable construction Light but also sturdy design Foot and transverse rubber feet for vertical or horizontal installation Operating panel guard Dual counter for operating hours and energy consumption Cable box Washable air filter Can be used with the air hoses with diameter 100 mm, 50 mm and 38 mm Technical details: Free exhausting air flow without adaptor plates: 1.250 m³/h Air pressure max.: 1.050 Pa Blower levels: variable Mains connection: 230 V / 50 Hz Power consumption: 170 W Sound level (distance 1,5 m): 73 dB(A) Dimensions (L x W x H): 355 x 430 x 235 mm Weight: 6 kg

Request for a quote

NOVELIS DEUTSCHLAND GMBH OHLER® - FLEXROHRE

Germany

By creating specialized aluminum alloys, pioneering new treatments and combining aluminum components with other materials such as paper, plastic and fiberglass, Novelis has become the global quality leader for the transportation manufacturing industry. We have created a range of transportation manufacturing products that provide insulation against heat, sound and gases, high strength so components remain effective under pressure, and superior flexibility for a full range of designs and implementations. Key Novelis aluminum components include heat exchangers, heat protection mats and sleeves, energy absorption elements, hoses, silencers and flexible tubes, including heat protection tubes, air ducts and exhaust pipes. Novelis is a leading supplier of light-gauge, narrow-slit aluminum fin stock (bare and clad) and brazing sheet used in the production of heat exchangers.

Request for a quote

ANTHERMO GMBH

Germany

Customized air-air heat exchanger for the industry (up to 1.000°C) Hot outgoing air and cold incoming air Very often hot exhaust gas gets out in the environment without any use. On the other hand cold incoming air must be lead into the production process and shall be warmed. This occurs for example very often within drying technology. In this case air-air heat exchangers can be used very efficient in heat recovery. As result you have great potential to save energy expenses. Three types of air-air heat exchangers The Anthermo GmbH delivers three types of different air-air-heat exchangers: cross-flow heat exchanger straight-tube heat exchanger flat-tube heat exchanger The technical figures (for ex. amount of air, temperature, pressure, waste of air) can be different for the air-air heat exchanger. Also the operating conditions and the environment conditions can vary from application to application.

Request for a quote

TROTEC GMBH

Germany

The TTV 3000 is a real whirlwind on every construction site. This unit is a true professional: distinctive German industrial design with built-in carrying handle, shock-protected switch and stackable polyethylene housing. And all other features of the TTV 3000 are nothing to hide either. With its high-performance, encapsulated fan, this conveying fan which is as robust as lightweight can variably transport fresh air over long distances into adjacent storeys or shafts and exhaust polluted air over equally long distances. Those are ideal conditions for the required air exchange rates for ventilation during channel construction works or welding. Hoses of up to 38 metres in length can flexibly be attached to the blow-out or suction side of the TTV 3000 because this axial fan is equipped with the respective connections on both sides.

Request for a quote

GEBRÜDER LÖDIGE MASCHINENBAU GMBH

Germany

The Lödige laboratory tablet coater has a modular design, so that integration of any components is customised according to the customer’s specific requirements. A dividable drum and a dividable nozzle arm allow processing of even very small volumes (0.6 l). The coater and the optionally available liquid supply station consist of Corian®, a highly resistant, light-weight, FDA-approved material, which is crucial for the particularly functional and modern design of the laboratory coater system. The laboratory coater is not just a “laboratory machine”, but a full coating system, in which process conditions comparable to those of Lödige production coaters are generated. The mobile laboratory coater incl. the drum for the tablets and drawer for the nozzle arm and tool form the base unit. In addition, the following equally mobile modules are available: — Air supply unit — Exhaust air unit — Liquid supply station (optional)

Request for a quote

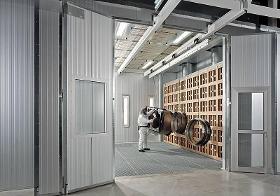

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pre-treatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The correct air budget is an often underestimated quality factor in surface treatment technology. Where heating, cooling, movement and filtration is concerned, a great deal of energy can be saved with innovative solutions. Supply air systems replace extracted air quantities and ensure: Supply and exhaust air systems Supply air systems ensure draught-free and clean ventilation of work rooms, while high-efficiency exhaust air systems with fans and filter systems are responsible for the necessary air exhaust. This takes place with the lowest possible use of energy and with the longest possible intervals between maintenance and cleaning operations. We also offer intelligent air solutions for dryers, pretreatment plants and cooling zones. Heat recovery A further important point is heat recovery. We can achieve up to a maximum of 80% heat recovery with the most diverse systems. Cross-current, rotary heat exchanger, heating pipe or circulatory systems – they all have their own advantages and efficiencies, which we integrate according to requirements during the planning of the plant.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Up to three processes – cleaning, painting and drying in one booth. Multi-process booth Just one booth for cleaning, painting and drying (up to three processes). Dry paint filter and wet cleaning in one booth – that is actually a contradiction in itself. Thanks to the separate air guidance, the exhaust air is fed downwards through the grating when drying and laterally through the filter boxes when painting, so that very little moisture enters the dry filter and virtually no particles get into the cleaning water. In order to prevent the ingress of particles, the gratings can additionally be covered over during painting. Any paint that does get into the cleaning water is usually already dry, so that no dilution in the classic sense takes place; instead, it behaves like small, filterable plastic balls. Advantages:

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Force-of-gravity separators, which are used as pre-filters or for the separation of large quantities of dust and swarf. Cyclone separator Cyclones are force-of-gravity separators. The separation principle is based on centrifugal force, which is produced by the tangential injection of the raw air. Cyclones are used as pre-filters or for the separation of large quantities of dust and swarf. The degree of separation of a cyclone is not normally sufficient to meet the usual environmental protection requirements. The cyclone exhaust air must be post-filtered in most cases. Product description A cyclone essentially consists of three parts: the intake cylinder, the cone and the immersion tube. In the intake cylinder, the raw air is brought into a circular path by means of tangential injection. Due to the taper of the subsequent cone, the speed of rotation increases sharply, so that the particles are pressed by centrifugal force against the outer wall and decelerated by friction, causing them to drop out of the air stream and fall down. The cleaned air leaves the cone in an upward direction via the central immersion tube. Cyclones are usually welded sheet steel structures. Cellular wheel sluices or, in individual cases, double-gate sluices are used for the pressureless discharge of the material. In order to increase the cyclone effect, or the degree of separation, counter-spirals with a pipe connection can be placed on top of the immersion tube. Further options are, for example, wearing devices, explosion pressure relief devices, control flaps, level monitoring devices and manufacturing in stainless steel or galvanised sheet steel.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

The term inline filter refers to an expandable, bolted, modular system. Depending on requirements, appropriate filter and air injection sections are connected together in series. The capacity range extends from approx. 10,000–300,000 m³/h. RS / RX filter The RS / RX series are a proven, expandable, modular system with low-pressure purge-air cleaning. Depending on requirements, appropriate filter and air injection sections are connected together in series. The capacity range extends from approx. 20,000–300,000 m³/h. RS / RX filters are suitable only for vacuum and positive pressure operation. The housing parts are usually made of 2 mm thick galvanised sheet steel. A thicker material in a painted execution as well as in stainless steel is also optionally available. The RS / RX series is 2.85 m wide. Filter hose lengths of 3 m (standard) and 4 m are available for this. The RSEC series has been designed for smaller air quantities and for above-roof installation. This series has a housing width of 2.4 m and 2 m-long filter hoses. The filter hoses are manufactured from polyester needle felt; the filtering direction is from the outside inwards. Filter cartridges and filter tubes are alternatively possible. The filter hoses are cleaned off using the material-preserving low-pressure purge-air system. The purging trolley inside the clean air compartment drives over the hose openings either continuously or controlled by pressure. In the direction of movement the first filter hose row is neutralised, while the second row is flushed from the clean air side. The third row is likewise neutralised. This results in a draught delay, which is necessary in order to allow the dislodged dust to fall into the discharge. The dust is discharged by a tried-and-tested drag conveyor with a downstream cellular wheel sluice. The return air pipes are provided with fire protection flaps and switching devices for exhaust air operation. The filter housing has been tested for resistance to pressure surges. Standard safety devices include likewise tested explosion pressure relief devices, fire extinguishing systems, mechanical and thermal monitoring systems as well as pressure-surge-resistant and flameproof cellular wheel sluices. The transport fan is arranged on the clean air side and is not exposed to swarf and dust. Hence, the conditions of a dust explosion zone do not prevail in the transport fan. RSV/RXV filter This series essentially differs from the RS/RX series in that its fans are arranged on the clean air side. RSV/RXV filters are suitable only for vacuum pressure operation. The capacity range extends from approx. 20,000 - 300,000 m³/h. The filter hoses are likewise cleaned off using the material-preserving low-pressure purge-air system.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

With high-quality filter tubes and PTFE diaphragms. Paint dust filters Wet painting also results in overspray. Overspray is the solid portion of the paint that is not taken up by the workpiece. According to the purpose of use, the overspray is moist and sticky immediately after release. It is captured by the exhaust air stream in the spray booth and fed to a filter. This can be, for example, a baffle plate filter, paper filter, fleece filter, glass fibre filter or also combinations of these. The adhesive effect causes the paint particles to adhere to the contact surfaces of the respective filter medium, as a result of which a good degree of separation is achieved. However, all these filters are storage filters, i.e. the filters clog up more and more during operation and cannot be regenerated. A filter exchange becomes necessary if the exhaust air rate of the spray booth falls below the minimum. This can be very time-consuming under certain circumstances and the work process must be interrupted in order to do it. To make things worse, not only must the filtered and bound paint residues be disposed of, but also the actual filter materials. Such tooling times are not justifiable for automatic, continuous or multi-layer painting processes. Continuous procedures such as automatically cleaned filters are likewise required for this. The humidity and the adhesiveness of the particles to be filtered are thereby the problem. In order to solve this problem, the paint particles should be relieved of their adhesive capability as far as possible whilst still inside the paint booth. Our patented ‘RTS-Rotation’ system is outstandingly well suited for this. The system is comprised of slowly rotating brush rollers, which take up the adhesive paint particles on the surface of the bristles and allow them to dry there. The bristles are automatically regenerated at pre-specified time intervals by combing devices that swing in at the rear of the brush rollers. The dislodged paint residues can then be removed and disposed of either manually during work breaks or automatically during operation. The degree of separation of this system is, however, insufficient to satisfy the environmental protection requirements concerning residual dust content in the exhaust air. A further filter stage is necessary for that. It must be assumed that the paint particles arriving here are to a certain extent still damp and sticky. For this we use special paint dust filters with high-quality filter tubes with PTFE diaphragms. If necessary, precoating agents (auxiliary dust) are used in order to neutralise the adhesive capability of the particles and to keep the dust layer on the filter elements permeable to air. The precoating agent is injected into the raw air pipe by means of special dosing units. The filter tubes are cleaned by means of compressed air impulse cleaning. The use of this technology requires special know-how. We have had the appropriate experience for almost ten years. The implemented plants have capacities ranging from 5,000 to 90,000 m³ /h. Because of the large number of different paint systems, individual experiments are usually necessary in our pilot plant in order to find the correct solution for the individual case.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

In this system, high air speed is used for intensive drying. A modular construction enable different dryer lengths, depending on the application. Temperature, air speed as well as supply and exhaust air can be manually set at the dryer. A frequency controlled version is available upon request. Flow meters monitor the exhaust air values and thus the correct function of the drying process.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

For its exhaust gas purification systems, Venjakob Umwelttechnik offers heat exchanger systems for utilizing the waste heat. These are characterized by: We build complete heat exchanger systems for heating water, steam, air, and gas or heat transfer fluid. The residual or excess energy contained in the clean gases of the Venjakob exhaust air cleaning systems often has sufficient potential to effectively support the actual production process, the building heater or other energy consumers. Whether as an individual system for heat transfer fluid, warm and hot water, hot air, and vapor, or combined as a downstream system solution for an exhaust air purification system - the planning, construction and production of the plant are done on an individual basis.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

The adsorption system (AD) from Venjakob Umwelttechnik serves to concentrate exhaust air flows containing low concentrations of pollutants, and is particularly suitable for removing extremely low to medium concentrations of solvent-based pollutants (VOCs). This machine is characterized by: During the adsorption process, the pollutants are physically retained on the surface of a solid material (e.g. activated carbon, zeolite). The pollutants are then removed /desorbed from the zeolite by means of a small, hot stream of air. Afterwards, the flow of exhaust air from the desorption process is cleaned by means of an exhaust air cleaning system (TI, RTO, CTO). By reducing the volume and by increasing the concentration, the operating costs of the downstream exhaust gas purification system can be kept very low and make autothermal operation possible among other things The rotor is mounted vertically on a shaft with bearing and rotated slowly in the air flow. During rotation, the adsorption and desorption take place simultaneously in separate chambers with cooling on a hydrophobic (water-repellent) incombustible zeolite material. For tough applications, versions can be provided with a removable wear layer and / or higher temperatures of up to 300 ° C for desorption. Two containers are operated alternately. While one of the containers is adsorbing, the other container can be desorbed The adsorption process can be used for smoothing pollutant concentration peaks. If pollutant peaks occur during a process that could lead to a potentially explosive mixture (> 25% lower explosion limit), they cannot be introduced into an incinerator. However, the pollutants may be temporarily stored in an adsorber and then be released during the desorption phase. In certain situations, the installation of an additional fixed bed adsorber (molecular sieve) may further enhance the process (safety, operating costs).

Request for a quote

OGE GROUP

Germany

Bases Exhaust diffusers Plenums Inlet Ducts Exhaust Ducts Exhaust Casings Inlet Collectors Exhaust Collector Air Intake Manifolds for gas turbines Piping Vessels Small high alloy parts

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This "stand-alone solution" is designed to meet flexible production requirements and can be used for solvent and water based paints. This spray coating machine is both economical and environmentally friendly. It can optionally be equipped with a belt cleaning system and/or a paper transport belt.This makes it possible to alternate between both modes of operation. A quick change between two paint systems (water/solvent based) is simple and fast. This makes it especially attractive for smaller companies to replace manual painting. Working width: 1,300 mm, Working height: 920-960 mm, Machine dimension: 1,900 mm (length) Feed speed: 2-4 m /min. Exhaust air volume: 7,000 m³/h, Supply voltage: 9.6 kW/ 12 A,

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

This machine has a twin cleaning unit, therefore it can be used for a dual application of water and solvent based paint systems. Reproducible results guarantee process reliability. The modular construction enables future expansion of the machine line and thereby ensures your investment for the future. Working width: 1,300 mm Working height: 920-960 mm Feeding speed: 3-8 m/min. Exhaust air volume: 7,000 - 10,000 m³/h Connect value: 20 KW Machine dimensions: 5,100 x 3,440 x 2,850 mm (L/M/H) The twin cleaning units of this flexible system technology enable a dual application for water and solvent based paint systems. The targeted paint-recovery by means of the patented V-belt system offers a maximum of profitability and environmental friendliness.

Request for a quote

VENJAKOB MASCHINENBAU GMBH & CO KG

Germany

With its VEN SPRAY PERFECT Venjakob has the innovative answer to all requirements encountered on the market. Based on decades of know-how in the realisation of high-performance spray painting plants, it is the flexibility of this new generation that convinces. In the long term, the modular system takes into account all production requirements. At the time of machine purchase, its concept realises all variants, from "one off batch size" through to large series production in the high-end range. The modular concept permits implementation of changing framework conditions at any point in time by retrofitting new modules, thereby making your investment future-proof. Working width: 1,300 / 1,600 / 2,200 mm Working height: 940 mm Feed speed: 3-8 m/min Exhaust air volume: 7,000 - 10,000 m³/h Connection value: 20 KW Machine dimensions: 2,280 / 2,800 mm (length of booth) The sophisticated spray gun control minimizes the rate of overspray. With the patented V-belt design up to 98 % of the liquid overspray can be reclaimed. The paint retrieved in this way is recycled into the paint process. Over and above, the innovative ventilation system improves the ecological energy balance. The short setup times, long service life of the filter elements, fast changing times for spray systems and automated paint-change procedures offer a very high degree of efficiency. The twin cleaning units allow the use of solvent-based paints as primer and the direct switchover in split seconds to the second cleaner operating with water-based paints. Maintenance and cleaning operations take place completely separate from the production process.

Request for a quote

WÖHLER GMBH

Germany

APPLICATION * Measurement of air speed, temperature, humidity at the air vents * Measurement of CO2 at the air vents * Detection of air leaks * Integrated measurement of volume flow * Direct measurement of volume flow at air vents in combination with the cone * Direct measurement of flow rate at the air nozzle in combination with a funnel ADVANTAGES * Easy handling with automatic identification of the cone * Two measurements in one step: determination of flow rate and evaluation of the inlet and exhaust air quality via CO2, T, RH * Selectable units: m/s, fpm, m3/h, CFM, °C, °F, cm2, Inch2 * Backlight LC display * Wöhler telescope handle e.g. for ceiling vents

Request for a quoteResults for

Air exhausters - Import exportNumber of results

28 ProductsCompany type

Category

- Heat exchangers (3)

- Pipes and tubes, aluminium (2)

- Ventilators and fans - domestic (2)

- Air purification - equipment and systems (1)

- Heat recovery systems (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Oiling - machines and systems (1)

- Pharmaceutical industry - machinery and equipment (1)

- Sandblasting equipment (1)