- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- bearing components

Results for

Bearing components - Import export

IGUS® GMBH

Germany

Shaft diameter d1 [mm]: Request iglidur® multi-component bearing Even higher loads The new iglidur® multi-component bearing combines the benefits of a hard polymer shell and a tribooptimized iglidur® core to make a unique bearing: Service lives previously not achieved in with an injection- molded polymer bearing heavy duty pivoting applications even beyond a radial load of 120 MPa show the potential. Lubrication-free wear-resistant Extremely shape stable Corrossion-resistant Application areas: Agricultural engineering, utility and construction vehicles, mechanical engineering Dimensions according to ISO 3547-1 and special dimensions Chamfer depending on d1 d1 [mm]: f[mm]: Ø 1-6 0,3 Ø 1-6 0,5 Ø 1-6 0,8 Ø > 30 1,2 Shaft diameter d1 [mm]:

Request for a quote

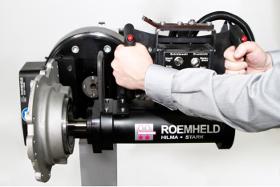

RÖMHELD GMBH FRIEDRICHSHÜTTE

Germany

Hydraulic pull-in device for mounting bearings max. pulling force 100 kN, stroke up to 200 mm, horizontal design Application The bearing press is suitable for the simple mounting of bearings, plain bearings or sleeves/bushings by hydraulically pulling them into the bearing seat. Main areas of application - Industrial assembly workstations - Mounting bearings in housings - Maintenance work - Bearing assembly on large/heavy components Description The bearing press is designed for the hydraulic insertion of bearings into housing components and is available in a horizontal design. Guided on a knuckle boom crane with a balancer (not included in the delivery), the bearing press can be used ergonomically anywhere and can also be mounted on a trolley. The pullin cylinder can be used either from the right or left by converting the hydraulic cylinder. The device is operated by means of a twohand control.

Request for a quote

TROTEC GMBH

Germany

Industrial condenser dryer DH 65 SThe compact industrial dehumidifier DH 65 S dries up to 80 liters per day This condenser dryer is an equally powerful and economic dehumidification solution for various dry keeping applications during industrial processes or product storage. In addition to the hot gas automatic defrost system, the DH 65 S comes with an aluminium tube evaporator without fins which permits an effective dehumidification performance even at a low humidity level. Moreover, the modular refinement of the electrical system and the water-bearing components of this industrial dryer was realized according to European standard. Hence, with the DH 65 S you have a particularly economic dehumidifier for reliable permanent drying applications. Owing to its sturdy swivel casters with RollStop catch, this drying unit can easily be transported from one application site to another.

Request for a quote

LT ULTRA-PRECISION TECHNOLOGY GMBH

Germany

We manufacture a large number of standard products as well as customer-specific special parts with optical surface qualities as contract manufacturing. You are welcome to get an overview in the category metal optics.You can also download all metal optics directly from our general overview or find them in our download area .In addition to such components with an optical function, we also manufacture precision parts for which a high geometric accuracy is in the foreground, such as air bearing components or micro-milled parts. With an extensive inventory of ultra-precision machines and the corresponding measuring technology, we manufacture with accuracies down to the sub-micrometer range and with roughness up to approx. 1 nm [Ra]. LT Ultra serves both single and series production. We look forward to your inquiry.

Request for a quote

SPIROL

Germany

Heat / Ultrasonic Inserts are designed for post-mould installation in thermoplastics. Heat and ultrasonic installation yield outstanding performance results. SPIROL offers several different series of Heat/Ultrasonic Inserts available in a long and short version of each thread size. Long lengths maximize torque and pull-out resistance, while short lengths are good for less stringent requirements at lower cost and shorter installation times. Some styles are available with or without a head. The head provides bearing surface for the mating component that also prevents jack-out (or when used in reverse, can prevent pull through). However, adding a head results in additional cost raw material of a larger diameter is required to create the head. Some non-headed Inserts are symmetrical – thus eliminating the need to orient the Insert prior to installation.

Request for a quote

DEMAG CRANES & COMPONENTS GMBH

Germany

Demag components for process cranes turn a crane into a fully fledged process crane, without the need for any additional design or development work. They're fast, safe and reliable, making these components extremely worthwhile elements of the Demag process crane engineering product line. The individual components – MPW open winch units, MPW open winch crabs and corner-bearing end carriages – are proven components that have been tried and tested for many years. They are individually configured to meet the specific requirements of your process crane. The variety of possible applications is virtually unlimited. See all the performance details and benefits on the product pages.

Request for a quote

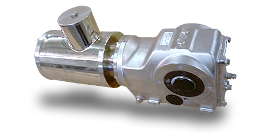

KAISER-MOTOREN GMBH

Germany

Stainless steel motors are used in sanitary areas such as in the food and beverage industry or in the pharmaceutical sector. The smooth surface of the motors is designed in accordance to the EHEDG guidelines to avoid dirt accumulation. To ensure longlasting and lowmaintenance operation, critical components such as bearings and seals are specially tested. Due to an extensive stock of motor components, standard and special motors can be delivered in a short time. Here are some of the common specifications Sizes 63160 0.18 to 22 kW 2 8 pole windings Special windings Enclosure IP66, optional IP69K Special shaft ends Terminal box or cables

Request for a quote

SPINDEL- UND LAGERUNGSTECHNIK FRAUREUTH GMBH

Germany

Bearings belong to those components which influence the production process considerably and contribute significantly to its quality. In addition they are normally subject to strong loads. A high quality and availability of equipment can be achieved by preventive maintenance based on its actual condition. Through the opportunity of reconditioning (rework) of bearings this process can be realized considerably more cost-efficient compared to exchange of bearings. Reconditioning of bearings and bearing units can already be economic from an outer diameter of 180 mm. The costs of reconditioning account to approx. 50 to 85 % of the sales price. Please consider the larger a bearing is the more economic is its reconditioning. Usually the lead time for reconditioning is even shorter than for newly produced bearings. In addition to repair of our own bearings we are also able to repair bearings made by other manufacturers.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

KFB Clarfeld Germany specialises in supplying automotive bearings with high quality and related parts to OE specification. We offer a wide range covering all popular bearings in order to support components for the majority of vehicles on the road today.

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

require high precision, large rated moving load, and high maximum rotation speed. By adopting the new technology of material processing, KFB has successfully manufactured bearings of long service life that are highly fatigue resistant and impact resistant. The types of bearings made by KFB for the metallurgical roller mills are: split bearings; unit rollers; support roller bearings; single row, double row, three row, four row cylindrical roller bearings, fully-loaded cylindrical roller bearings, spherical roller bearings. The use of split bearings appreciably facilitates assembly and repair operations compared to the use of nonsplit (conventional) bearings. It does away with the need for the disassembly and subsequent reassembly of intermediate parts and mechanisms, which is required when replacing conventional bearings. It also reduces costs and production losses. If provided with efficient cooling, reliable lubrication and proper sealing, split-bearing components can be used...

Request for a quote

KFB CLARFELD GERMANY GMBH

Germany

Axial needle cage assemblies Axial needle cage assemblies, composed of synthetic or metal axial cage assemblies with integrated needle rollers, have an extremely low overall height. They tolerate high axial forces acting in one direction, radial forces must be taken up separately. The deployment of axial needle cage assemblies requires that hardened and bevelled thrust surfaces may be used as raceways. Thrust bearing washers Thrust bearing washers are punched, hardened and polished and can be used as shaft or housing washers. These washers are appropriate when the adjoining machine part when not hardened, is rigid enough and of a stable form. Axial needle bearings Axial needle bearings are components made up of axial needle rollers and cage assemblies and axial washers with centring bore. They can be combined with needle sleeves, needle bushes and needle bearings. The thrust surface for the cage assembly must be hardened and bevelled. The product types AXK and K are applicable here

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft and ball bearings in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - optional potting against water jets (IP 69K) - electrical connections via round plug or lead exit.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft and ball bearings in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - optional potting against water jets (IP 69K) - electrical connections via round plug or lead exit.

Request for a quote

TWK-ELEKTRONIK GMBH

Germany

Robust case with wall thickness of 5 mm either in seawater resistant aluminum or in stainless steel - shaft and ball bearings in stainless steel - rotating components with permanent magnet in front chamber - electronic circuit with ASiC and Hall elements and interface components fitted within main chamber, separated from rotating components by a metallic wall - optional potting against water jets (IP 69K) - electrical connections via round plug or lead exit.

Request for a quote

MSE FILTERPRESSEN GMBH

Germany

Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient. THE RUBBERIZED FILTER PRESS OF MSE AS PROTECTIVE MEASURES AGAINST AGGRESSIVE SUSPENSIONS In a complex process, the load-bearing filter press components are coated with a layer of 3mm thick plastic. In the case of the rubberised filter press, the hydraulic stands, feed stand, pressure plate and supporting beams are hard rubberised and the smaller components are made of polypropylene. It is also possible to rubberise only the components in contact with the product, such as the feed stand and the pressure plate. The composition of the rubber coating depends on the special surface requirements of our customers.

Request for a quote

WALTHER TROWAL GMBH&CO.KG

Germany

PARTS CLEANING FOR REPAIR AND MAINTENANCEImportant components require thorough and regular cleaning and maintenance, especially in industry, mechanical engineering and the automotive sector. Our TRT 83 x 37 cleaning trough removes grease, lubricants and other residues thoroughly and reliably, before the components are reinstalled. WHICH WORKPIECES CAN BE CLEANED? You can use the TRT 83 x 37 cleaning trough to effortlessly clean workpieces measuring up to 80 cm in length and 30 cm in diameter. Here are some examples: Bearing shells and covers Engine components Gearbox components Shafts and axles Labyrinth rings Bearings, bearing units and bearing housings

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

HEIDENHAIN angle encoders with integral bearing are characterized in particular by very high system accuracy. The integral bearing in the encoders eliminates any effect on measuring accuracy from the bearing of the machine components. The integrated stator coupling in the RCN/RON/ECN series encoders guarantees lowest possible error from the effect of tolerances in the shaft coupling. All angle encoders with integral bearings feature shaft seals that ensure resistance to contamination (IP64 protection). These encoders enjoy an entire spectrum of possible applications in machine tools, measuring machines, telescopes, printing machines and many other areas. Absolute measuring method Hollow shaft diameter (up to 50 mm) Integrated stator coupling Simple installation Typical field of application: Rotational axes with reduced accuracy requirements

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STI GROUP / STI - GUSTAV STABERNACK GMBH

Germany

The perfectly matched components promote the product launch of Unilever at the POS both as product bearing components and as components that enhance product presentation. The display made entirely out of corrugated board creates an outer space ambience and showcases the product for the target group. An archway made of elliptical columns serves as an eye-catcher even from a distance. Floor stickers draw shoppers to the promotional zone.

Request for a quote

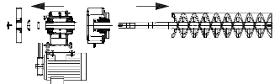

PALLMANN MASCHINENFABRIK GMBH & CO. KG

Germany

Characteristics, Function The new refiner feed screw bearing system is designed in a very maintenance-friendly wayThe bearing components, specifically the feed screw can be exchanged in no time at all and thereby increases the availability of the system.It is also possible with this design to provide the feed screw with a mechanical seal. Advantages Low downtimes Significantly increased system availability Available with mechanical seal Old feed screw can still be used

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

The LS 1679 has been specially developed for press brakes. The basis for its high accuracy and repeatability is its precise glass scale and high-quality integral bearing. Thanks to the material of its steel track and steel roller bearing component pair it is very robust. There are many variants for connection to the machine frame, whereby the ball coupling offers the most degrees of freedom. Besides the standard resolution with 5 µm measuring step there is also a variant with 1 µm. For perfect mounting to the two C-columns there are variants with rightward and leftward cable outlets.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

A major hallmark of HEIDENHAIN angle encoders is their very high system accuracy. This makes them particularly advantageous in demanding applications for machine tools, measuring machines, telescopes, printing machines, etc. Because the bearing is integrated into the encoder, machine component bearings have no effect on the measuring accuracy.

Request for a quote

DR. JOHANNES HEIDENHAIN GMBH

Germany

A major hallmark of HEIDENHAIN angle encoders is their very high system accuracy. This makes them particularly advantageous in demanding applications for machine tools, measuring machines, telescopes, printing machines, etc. Because the bearing is integrated into the encoder, machine component bearings have no effect on the measuring accuracy.

Request for a quoteResults for

Bearing components - Import exportNumber of results

23 ProductsCountries

Category

- Measurement - Equipment & Instruments (5)

- Bearings, roller (3)

- Potentiometers (3)

- Bearings - ball, needle and roller (1)

- Bearings, ball (1)

- Adjustment - machine tools (1)

- Cranes and gantries (1)

- De-humidifying equipment (1)

- Drainage systems and equipment (1)

- Electric motors - dC (1)

- Mechanical engineering - custom work (1)

- Metallurgy and iron and steel industry - machinery and installations (1)

- Plain bearings (1)

- Screw cutting - steels and metals (1)