- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic belts

Results for

Automatic belts - Import export

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

VKF RENZEL GMBH

Germany

The "Easy" barrier stand is characterised by its particularly low base plate. This barrier post is ideally suited for the construction of personnel guidance systems as well as the marking of non-accessible areas. The included belt rewinds automatically and can be replaced if necessary using the belt cassette. Place the barrier post "Easy" in places where a flat stand is useful due to heating, sales counters or similar. You can choose the colour for belt and post in our offer to match your project.

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

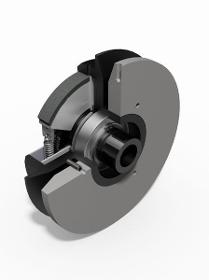

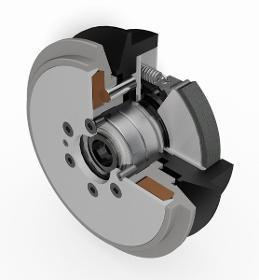

The centrifugal clutch with pulley, like the centrifugal clutch with automatic belt tensioners, offers the benefit of a compact build in which an additional tensioning roller is not needed in the belt drive. In the centrifugal clutch with adjustment disc, the drum is formed as a regulating hub. The regulating hub adjusts the belt pre-tension. The regulating nut is secured with grub screws in the adjustment area and can be set smoothly. These centrifugal clutches are also used in shaker plates.

Request for a quote

AMSBECK MASCHINENTECHNIK GMBH

Germany

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 HighSpeed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157 Operational Safety High level of operational safety through the strip design. Smooth Transfer Closed belt surface for a smooth package transfer. Belt Tracking Integrated Automatic belt track fittings integrated. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low structural height. (approximately 250mm)

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

The ultra-modern complete system EBS 2500 enables high-resolution printing on a wide variety of surfaces, even on porous or highly absorbent ones. This makes it particularly suitable for use as a replacement for expensive labels. — Lightweight, compact and easy to install — Convenient creation & editing of artwork designs using a web browser and their transfer via an Ethernet interface — LCD 5.7'' touch color display for printer control, file management & maintenance — Works virtually with any operating system - no separate printer software required — Static text & many variants of variable text (including counter, date, time, expiration date) — Rotatable texts, graphics, barcodes — Freely selectable printing direction (to the right/left, upside down) — Automatic measurement of the conveyor belt speed — Multi-level user management with access control

Request for a quoteResults for

Automatic belts - Import exportNumber of results

9 ProductsCountries

Company type

Category