- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- automatic belts

Results for

Automatic belts - Import export

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. GEM 350 / GEM 360 / GEM 820 WITH ADJUSTABLE FORMAT AND WITH UPPER AND LOWER DRIVE BELTS The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close boxes high and narrow. Ideal for fixed format boxes close (with constant height and width). Structure of the machine body made of sheet steel bent, bolted and painted. The movement of the cartons is done by two side drive belts driven by a single motor, adjustments for the different formats are made through flywheels. The machine is equipped with 4 wheels with brakes.

Request for a quote

FERPLAST SNC

Italy

COMPLETELY AUTOMATIC STRAPPING MACHINE MOD. JN85-M Fully automatic strapping machine with high speed and reliability. The machine is equipped with motorized belts for insertion in packaging lines, aluminum arc with multiple flaps to facilitate the launch of the strap and the subsequent release and electrical system with Omron PLC. The electrical panel of the machine can manage the motorized loading and unloading belts (optional) and allows the use of the strapping machine in lines without operator.

Request for a quote

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. GEM 350 - GEM 360 - GEM 380 WITH ADJUSTABLE FORMAT AND WITH UPPER AND LOWER DRIVE BELTS. The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close boxes high and narrow. Structure of the machine body made of sheet steel bent, bolted and painted, the movement of the cartons is done by four drive belts flat, two lower and two upper, driven by a single motor, adjustments for the different formats are made through flywheels. The box has to get on the work surface with the top flaps closed. The machine is equipped with 4 wheels with brakes.

Request for a quote

FERPLAST SNC

Italy

CARTON SEALER MACHINE MOD. FP 9037 - UPPER AND LOWER BELTS The two heads simultaneously apply a strip of tape taping above and below the box. Ideal for close fixed format boxes (with constant height and width). Structure of the body in painted steel. Movement of boxes happens via two lower dive belts and two upper drive belts, adjustments for the different formats are carried out using flywheels. The machine is equipped with idle rollers 400 mm length for loading and unloading. The machine is equipped with wheels with brake.

Request for a quote

FERPLAST SNC

Italy

MODULAR LINE SEMIAUTOMATIC ANGULAR PACKAGING MACHINES Semi-automatic, angular machines offer maximum packaging flexibility, and a quality product at a competitive price. MODULAR 50S and MODULAR 70, which have recently been updated and revised, can be used to package products using any material, producing highly attractive results. MODULAR LINE uses an electronically controlled sealing system and the very latest safety devices. The lines can be used in automatic or semi-automatic mode, and the operating programs can be customised in order to simplify the packaging process and maximise productivity. MODULAR 50S and MODULAR 70 can also be used with the TUNNEL.

Request for a quote

FLOTTWEG SE

Germany

The Flottweg Belt Press is in use in many mechanical separation technology areas, especially in the production of fruit juice, concentrate and vegetable juice. But other products, too, such as algae extracts, coffee grounds, herbal extracts, soy, and starch, are produced using belt presses. Flottweg Belt Presses: ►Maximum quality: You obtain not just the best possible quality, also maximum yield at lower costs. ►Minimum operating difficulty: Its clear design makes it easily accessible for cleaning, operation and maintenance. Automatic belt control provides optimum tension and guidance of the belts. ►Long-lasting design: The consistent use of stainless steel means that the belt press not only meets the requirements of strict hygienic standards, also is built tougher to last longer. ►Flottweg Service: We are at your side at any time with years of experience and comprehensive know-how.

Request for a quote

VKF RENZEL GMBH

Germany

The "Easy" barrier stand is characterised by its particularly low base plate. This barrier post is ideally suited for the construction of personnel guidance systems as well as the marking of non-accessible areas. The included belt rewinds automatically and can be replaced if necessary using the belt cassette. Place the barrier post "Easy" in places where a flat stand is useful due to heating, sales counters or similar. You can choose the colour for belt and post in our offer to match your project.

Request for a quote

SHANGHAI NPACK AUTOMATION EQUIPMENT CO., LTD.

China

Flat surface plane labeling machine can work for all kinds of objects with plane, flat surface, side surface or large curvature surface such as bags, paper, pouch, card, books, boxes, jar, cans, tray etc.Widely used in food, medicine, daily chemical, electronic, metal, plastics and other industries. It has optional date coding device, realize date coding on stickers. Features You Can Not Ignor: 1. It can label for any products with flat surface. More flexible arrangement for manufacturing schedule. 2. The labeling head convenient to adjust, the labeling speed is automatically synchronous with the conveyor belt speed to ensure precise labeling. 3. The speed of conveyor line, the speed of pressure belt and the speed of label output can be set and changed by the PLC human interface. 4. Use famous brand PLC, stepping or servo motor, driver, sensor, etc, good quality components’ configuration.

Request for a quote

FERPLAST SNC

Italy

The shrink tunnel, equipped with temperature adjustments, height and speed, is incorporated in order to make the machine compact and versatile, suitable for series production. The welding time is electronically set and the absence of fumes is ensured by teflon-coated blades. The sealing bar motorized, equipped with security system, the closed circuit cooling plant and motorized scrap-winder, are part of the standard equipment of the machine. FEATURES Digital panel with 6 programs Descent sealing bar manual or automatic Discharge conveyor for product Legs with locking wheels Only welding and welding + retraction Sealing bars with closed-circuit cooling system and patented safety system Emergency switch Teflon coated sealing bars Electromechanical automats Welding speed automatic controller Motorized conveyor belt with adjustable height Motorized scrap-winder Air flow shrink tunnel swiveling Adjustable temperature with electronic temperature controller

Request for a quote

AUROMAK MAKINA

Turkey

The tunnel-type hot water and multi-purpose washing, rinsing, drying and lubricating system is an effective cleaning and treatment method of ten used on a large scale in industrial production processes. This system is located inside a tunnel where materials move automatically on a convey or belt.

Request for a quote

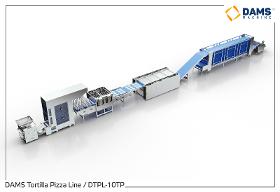

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Up to 11000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for10.000pcs/hour) 6 pocket stainless steel dough carrier tray 278 pieces active tray 1668 active pockets Removable and washable UHMWPE mesh pockets 2″roller chain for tray transport Main frame is stainless steel tube. Total power 1.5 kW.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 11000 pcs/hour capacity Weigh trange 40-140 grams (±2 gr) 6 pieces 50mm diameter pistons Changable outer drum for different weights 6 row outlet belts Automatic oil lubrication Variable speed controls for main drive and rounding unit Flour duster Dough bunker capacity is 210 kg Total power 5 kW 7 inc HMI TouchPanel , PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 6000pcs/hour) 6 pockets stainless steel dough carrier tray 139 pieces active tray 834 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chainfortray transport Main frame is stainless steel tube. Total power 1.5 kW Easy Access for maintenance Safety switches on doors.

Request for a quote

DAMS MACHINE

Turkey

DIVIDER & ROUNDER Upto 7000 pcs/hour capacity Weight range 40-140 grams (±2 gr) 4 pieces 50mm diameter pistons Changable outer drum for different weights 4 rows outlet belts. Automatic oil lubrication Variable speed controlsfor main drive and rounding unit Flour duster Dough bunker capacity is 140 kg Safety switches on doors Total power 5 kW 7 inc HMI Touch Panel PLC control INTERMEDIATE PROOFER Proofing time 10 minutes (for 4000pcs/hour) 4 pockets stainless steel dough carrier tray 146 pieces active tray 584 active pockets Removable and washable UHMWPE mesh pockets 2″ roller chain for tray transport Main frame is stainless steel tube Total power 1.1 kW Easy Access for maintenance Safety switches on doors

Request for a quote

F.E.S. GMBH

Germany

BK 0.5 US/K – BK 2.5 US/K (0.5 – 2.5 m² filter area) Dry cake discharge No fleece consumption compact systems are used for cleaning contaminated cutting fluids in metal processing and rolling mill operations. Cleaned cutting fluids have longer lifespan, improve the surface quality of workpieces or rolled goods, and help dissipate heat at the processing or forming location. Advantages: Fully automatic operation Excellent filtration results without fleece consumption Minimal carryover of cutting fluid Dry cake discharge Low maintenance requirements Full-flow filtration Maximum lifespan of cutting fluid Option for emergency operation with fiber fleece The cleaned cutting fluid is supplied to the system pump (A) from the clean tank (B) of the processing machine (C). The contaminated cutting fluid is introduced into the dirt tank (E) of the folding belt filter system through the lifting stations. The internal processing of the system consists of two steps: “Filtration” and “Regeneration.”

Request for a quote

FORMEX MAQUINARIA

Spain

•Continuous dosing as the belt advances. •Manual adjustment of the dosing head height, which lowers automatically for each dose. •Adjustable belt speeds on the screen. •The dosing control is managed by a servomotor system that gives the machine greater speed, smoothness and precision to work with a wide variety of densities. •Thanks to the servomotor the user can control the dosage quantity electronically as well as loading and/or unloading speeds. •Anti-drip movement with suction of the product. •All this with great precision and with the facility to pre-record these parameters in more than 100 recipes.

Request for a quote

MARTIN GROUP SRL

Italy

double heating system with pre-heating that concurs to fuse with very low temperature respect to the standard temperature pressure system with “OUT” function for very delicate woven inside and outside belts cleaning devices carbon/graphite lower belt separation blade automatic turn ON and turn OFF by digital timer COUPLING, LAMINATION, TRANSFER, APPLICATIONS - COMPLETE LAMINATION LINE THAT CONCURS THE COUPLING OF 2 OR MORE LAYERS OF WOVEN WITH INTERLININGS, WEB GLUE OR FILM GLUE DIAGNOSTIC ON THE CONTROL PANEL introducion of the several rolls of wovens, interlinings, web glue or film glue by engine rolls perfect syncrony between fusing machine winding module and rewinding unit by inverter automatic cut machine availabilty for worked parts winding unit with vertical and horizontal control for a perfect alignment of the woven rolls during the winding fusing machine connected to the winding and rewinding module by inverter exit zone with rewinding unit equipped

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

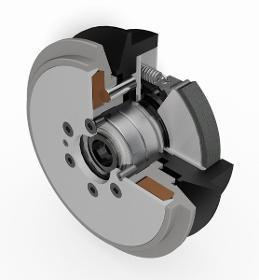

AMSBECK MASCHINENTECHNIK GMBH

Germany

For centrifugal clutches with belt outputs, the belts must be pre-tensioned in order to maintain the pressing force required to transfer force. Usually, tensioning rollers are used in the belt drive for this purpose. However, tensioning rollers are hard to use with short axle distances. The tried-and-tested centrifugal clutch with integrated, automatically acting belt tensioner compensates the length changes of the V-belts by adjusting the diameter of the pulley. Typically, these centrifugal clutches are used in high-quality reversible shaker plates.

Request for a quote

INOVA TECHNOLOGY GMBH DISTRIBUTION OF MEDICAL TECHNOLOGY

Germany

Welcome to our industrial document shredder area. These high-performance document shredders shred very large amounts of paper, media and other data carriers in a single pass, making them perfect for an office building. The waste is normally transported from the individual departments to the document shredder and shredded there at a fixed location. These industrial document shredders shred between 100-2100 kg of paper waste in one hour. Some models can shred bulky objects as well as complete folders with metal inserts. Industrial document shredders can usually be equipped with automatic loading and a conveyor belt. Financing options are available for all industrial document shredders (please give us a call). If you have thousands of documents or large quantities of paper in your warehouse every month, then our industrial document shredder is just right for you.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

MDF forming lines consist of machines for forming and monitoring the bre mat. Additional devices for quality monitoring complete the function. The plant modules can be adjusted to the respective requirements thus preparing the mat optimally for its compaction in a ContiRoll®. The equipment is designed to produce board thicknesses between 1.5 and 40 mm without any problem. The forming belt conveyor is a modular design as well tuned to plant output and feasible board formats. Features Forming belt with pneumatic tensioning station as well as electric drive station and integrated automatic reject m Integrated belt scale for controlling the mat former output to ensure consistent product quality Mat moisture meter Automatic edge trimming system ex prepress Monitoring equipment to prevent steel belt damage peak detectors metal detector

Request for a quote

FMH CONVEYORS INTERNATIONAL LIMITED

Germany

From 0 to 2.5 meters per second. The Motion06 Full Belted Merge brings the packages or parcelled cargos onto the track like no other. Thanks to our sophisticated design using a belt, safe and fast transportation of the parcelled cargo are ensured. In connection with the Motion06 HighSpeed Diverter, the merge can also be used to transfer packages outwardly at different angles. FBM 112/157 Operational Safety High level of operational safety through the strip design. Smooth Transfer Closed belt surface for a smooth package transfer. Belt Tracking Integrated Automatic belt track fittings integrated. Short Lengths Available Extremely short construction lengths are possible. Low Height Possible Low structural height. (approximately 250mm)

Request for a quote

GIZELIS ROBOTICS

Greece

Regardless of the material to be handled (sack, carton box, tin or bottle), this robotic arm picks-and-places with utmost precision (≤0,25mm). It may also handle multiple product lines concurrently, as well as different types of products by means of special grippers, thus further increasing the degree of system flexibility. A comprehensive palletizing line includes, apart from the robot and gripper set, product conveyor belts, automatic pallet feeder for attaining higher speeds, ready pallet roller conveyors, pallet transport wagon for large areas, and automatic pallet wrapper with stretch film, automatic strapping machine, and safety fence for personnel safety.

Request for a quote

EBS INK JET SYSTEME GMBH

Germany

The ultra-modern complete system EBS 2500 enables high-resolution printing on a wide variety of surfaces, even on porous or highly absorbent ones. This makes it particularly suitable for use as a replacement for expensive labels. — Lightweight, compact and easy to install — Convenient creation & editing of artwork designs using a web browser and their transfer via an Ethernet interface — LCD 5.7'' touch color display for printer control, file management & maintenance — Works virtually with any operating system - no separate printer software required — Static text & many variants of variable text (including counter, date, time, expiration date) — Rotatable texts, graphics, barcodes — Freely selectable printing direction (to the right/left, upside down) — Automatic measurement of the conveyor belt speed — Multi-level user management with access control

Request for a quote

EFARGE MAKINA IMALAT SAN. VE TIC. A.S.

Turkey

Disc Diameter : Ø 300 - 400 Size Calibration System : Servo (Ball Screw + Linear Guides) Max. Cutting Thickness : 50 mm Min. Cutting Width : 200 mm Max. Belt Width : 1200 mm Control Panel : PLC + SCREEN Automatic Water Valves : Available Conveyor Belt Speed : 0-8 mt/dk Line Length ≌ 10000 mm

Request for a quote

ALPER MAKINA CHOCOLATE PRODUCTION LINES

Turkey

Cooling Tunnel – Our cooling tunnel is used for cooling chocolate coated biscuits,jelly, nougat, fondant and similar products. – Belt widths 400,600, 800,1000, 1200 mm – Cooling unit is in the middle part of the tunnel. Two blowers supply the necessary air current. – Tunnel temperature is controlled by a digital thermostat. – Tunnel temperature can be down to 0°C. – Belt sped is controlled by electronic frequency drive. – Covers are insulted. – The tunnel can be cleaned by opening the top covers. – Tunnel has a automatic belt adjustment system. – Sharp edged infeed. – Tunnel has scrapers

Request for a quote

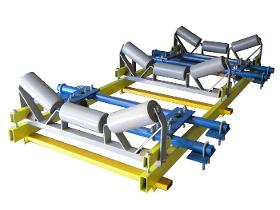

SPF SWEDA LTD

Ukraine

Automatic belt scales (belt weigher) SWEDA VK are designed for continuous measurement of the mass of bulk and lumpy materials transported by belt conveyors and indication on a digital display of the current conveyor performance and the value of the mass of weighed bulk and lumpy materials on a accrued total during commercial, accounting and technological operations. Features: - Accurate weighing and accounting of material in the flow (± 0,5%); - Measurement and indication of momentary сapacity; - Summation and indication of the total weight per shift, day, total; - Wide operating temperature range; - Possibility of calibration and verification without material overweight; - Modular construction, which makes it easy to transport and mount the scales directly at the enterprise; - Data output to a remote display and a computer as part of the process control system; - More than 1000 serial samples are in operation in 15 countries.

Request for a quote

PL CONTROL LTD.

Bulgaria

It is a combination of a manipulator with Cartesian X-Y kinematics and a belt feeding transport packaging. The packaging products come directly from the output of the last machine in the production process. The particular implementation is packing oil packets that enter the packing system into a group of 15 pieces every 2.5 seconds. The manipulator monitors each incoming group and automatically orientates itself to its position on the inbound conveyor belt. After taking the group by vacuum, the electro-mechanical system physically compresses the group so that it enters the transport pack. The process is repeated until the transport packaging is full. This is followed by the automatic closing and positioning of a new transport packaging. The whole system is subject to modification, depending on the product packaged and the pace of work, transport packaging and physical space of the workspace.

Request for a quote

DISPA MACHINE

Turkey

• Semi-automatic double miter for cutting profiles and solid material in steel and non-ferrous material and an excellent price-performance ratio • Manually swiveling saw frame with hydraulic clamping for optimal • Hydraulic clamping of the horizontal vise • Automatic saw frame raising on the cut end • Double speed motor 1.0/1.3 KW Gearbox • Sensitive cutting pressure regulation function of the material properties • Hydraulic-mechanical belt tension • Tape guide with hard metal pads sheets and rolls • Thermal overload protection and no-volt release • Automatic shut-off after cut end • Automatic belt break protection Driven

Request for a quote

CARONI S.P.A.

Italy

Tough and simple to use The tough and simple-to-use TL series, available in versions TL0900 - TL1200 and TL1500, is specialized in cutting grass on any type of terrain. Three rotors can be used: type A for a normal cut, and type F, fitted with twice the number of blades with respect to type A, to give a more accurate and closer cut, and type P, which thanks to the horizontal cutting edge of the blade permits an excellent finish cutting of the grassland. These mowers have fixed tractor hitches, and their drive is provided by 2 trapezoidal belts with automatic spring-adjusted tensioner. TM 1300 - TM 1600 TM 1900, which can also be mounted with an additional rotor with respect to the TL series. This B type rotor is ideal for cutting down bushes and can therefore be used for clearing undergrowth, uncultivated fields, motorway verges. It can also be used for stalk shredding after crop harvesting. The TM series differs from the TL series in that its hitches and 3rd point have two different positions, and three belts are used for the drive, which is decidedly more substantial in the TM series. Both series, however, guarantee the correct cutting height by using an adjustable rear roller and a scraper, which keeps the mower clean. A set of side skids can be supplied upon request to suit the various different types of terrain. Both the TM and TL series mount steel protections as a standard to safeguard the driver when the rotor is in operation. The hitches, which are also standard fittings, allow the mower to be used with any type of tractor. HYDRAULIC SHIFT KIT FOR FLAIL MOWERS, SERIES TL AND TM It can be applied to all models of TL and TM series, 1200 to 1900 mm long. This hydraulic shift kit is an actual optional accessory to be ordered with the machine or separately. The kit makes the machine particularly agile on any kind of ground for easy mowing, even in areas difficult to reach. It permits to improve the performance of your flail mower with no need for purchasing a new machine equipped with a specific shift frame. SHIFTING DIAGRAM

Request for a quoteResults for

Automatic belts - Import exportNumber of results

30 ProductsCompany type

Category

- Packing and packaging - machinery and equipment (5)

- Bakery and confectionery industry - machinery and equipment (4)

- Clutches (2)

- Automation - systems and equipment (1)

- Beverage industry - machinery and equipment (1)

- Blades for saws and cutting machines (1)

- Bottling and filling - machinery and equipment (1)

- Cakes and pastries, factory-baked (1)

- Cocoa and chocolate - machines and equipment (1)

- Conveyor belts (1)

- Conveyor systems (1)

- Electric and electronic components - machines for manufacturing (1)

- Food Industry - Machines & Equipment (1)

- Industrial equipment hire (1)

- Industrial washing facilities (1)

- Laminating machines and equipment (1)

- Marble cutting machines (1)

- Package sealing machinery (1)

- Palletising machinery (1)

- Plate glass and mirrors (1)